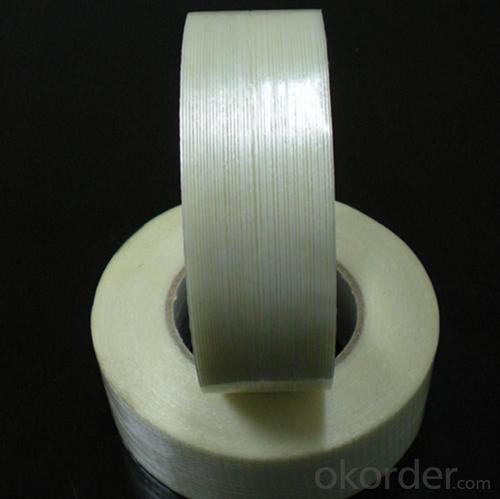

High Quality Fiberglass Tape FGT-200 for Heat Machine Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1x20' FCL roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Genaral Information Of High Quality Fiberglass Tape FGT-200

1. Filament / fiberglass tape is with PET film and bi-directional fiberglass.

2. The tape is with high tensile strength, used for palletizing, holding, bundling, reinforcing, heavy duty packing, carton packing & sealing.

3. Standard cut roll packing: one roll per plastic bag, then into cartons. We can also offer special packing as per customer's requirements, such as label, core printing and sticker.

acking: Bi-directional Fiberglass + PET film

Adhesive: Hot melt rubber based adhesive

Total Thickness (adhesives + backing): 200micron

Initial Tack: more than 20# steel ball

Tensile Strength: more than 120N/25mm

Peel Adhesion: 13 N/25mm

Holding power: not less than 50h (1kg/25mm)

Mesh: 6/6

Temperature resistance: 60C

Elongation: 1.00%

Sizes:

Jumbo Roll: 1.02 x 1000m

Cut Roll: As per customer's requirement

Packing Of High Quality Fiberglass Tape FGT-200

Core I.D.: 3” (76mm?1)

Jumbo Roll:1280mm x 4000m

Cut Roll: As per customer’s requirements

Application Of High Quality Fiberglass Tape FGT-200

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

Service Of High Quality Fiberglass Tape FGT-200

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

Handing and Storage Of High Quality Fiberglass Tape FGT-200

Handling procedures:Caution with edge of sheet. After using this sheet, wash hands.

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Stability and Reactivity Of High Quality Fiberglass Tape FGT-200

Chemical Stability: Stable and non-reactivity

Conditions to Avoid: Away from high temperature

Incompatibility with various substances:specific materials/condition to avoid.

Hazardous Decomposition Products:Thermal decomposition will produce mainly C02,and slightly CO.

Hazardous Polymerization:Can not occur

Transport Information Of High Quality Fiberglass Tape FGT-200

Not a hazardous material for DOT shipping.

UN:None

Packaging sign:According to the buyer

Packaging Category:No information found/According to the buyer.

Shipping Marks: According to the buyer

Remarks Of High Quality Fiberglass Tape FGT-200

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: 10%; Width: 3mm; Length: Cut Roll & Log Roll 0.3m, Jumbo Roll 0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: Can packaging tape be used for sealing musical instruments or equipment?

- Packaging tape is not recommended for sealing musical instruments or equipment. It may not provide adequate protection or support, and could potentially damage the instrument or equipment. It is best to use specialized products designed specifically for sealing and protecting musical instruments or equipment.

- Q: Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can definitely be used for other purposes besides packaging. Due to its strong adhesive properties and durability, it can be used for a variety of tasks. For example, it can be used for household repairs such as fixing a broken book spine or securing loose cables. Additionally, it can be used for crafting projects like creating temporary or permanent decorations, making durable envelopes, or even in DIY projects like creating makeshift labels or organizing items. Furthermore, packaging tape can also be used for temporary fixes, such as sealing small leaks or cracks in pipes or containers until a permanent solution is found. The versatility of packaging tape makes it a handy tool to have around the house or office for various purposes beyond just packaging.

- Q: Can packaging tape be used for securing shipments during transit?

- Yes, packaging tape can definitely be used for securing shipments during transit. Packaging tape is specifically designed to provide a strong and reliable seal for packages, ensuring that they remain intact and protected during transportation. It is commonly used for sealing cardboard boxes, securing bubble wrap or other protective materials around items, and reinforcing the closure of packages. Packaging tape is durable, easy to use, and provides a secure bond, making it an ideal choice for securing shipments during transit.

- Q: Can packaging tape be used for sealing packages with irregular or uneven surfaces?

- Yes, packaging tape can be used for sealing packages with irregular or uneven surfaces. Packaging tape is designed to adhere to various types of surfaces, including those that may be uneven or irregular. The strong adhesive properties of packaging tape ensure that it securely seals the package, even on surfaces that may not be completely flat or smooth. Additionally, packaging tape is flexible and can conform to the shape of the package, allowing for effective sealing on irregular surfaces. However, it is important to ensure that the tape is applied evenly and pressed firmly onto the surface to maximize its sealing capabilities.

- Q: Does packaging tape leave residue?

- Yes, packaging tape can leave residue on surfaces after it is removed.

- Q: Can packaging tape be used for sealing industrial or manufacturing goods?

- Yes, packaging tape can be used for sealing industrial or manufacturing goods. It is commonly used in industries and manufacturing settings to secure and seal boxes, packages, and other items for storage, transportation, and shipping purposes. Packaging tape is designed to provide strong adhesion and ensure the integrity of the sealed goods during handling and transit.

- Q: What's the tape for sealing tape?

- The base material of the sealing adhesive tape is BOPP film.BOPP is a very important flexible packaging material, and has been widely used. BOPP film is colorless, odorless, tasteless, non-toxic, and has high tensile strength, impact strength, rigidity, toughness and good transparency. It is a high quality substrate for making transparent sealing tape. BOPP film has low surface energy, and it needs corona treatment before gluing or printing. However, the BOPP film has good printing adaptability after corona treatment. It can be printed by printing and has a beautiful appearance, so it is often used as the surface material of composite films. BOPP film is also inadequate, such as easy accumulation of static electricity, no heat sealing and so on. In the high-speed production line, BOPP film is easy to generate static electricity. Electrostatic eliminator is necessary. In order to obtain the BOPP heat seal film, can be on the surface of BOPP film after corona treatment coating heat sealing resin glue, such as PVDC, EVA latex latex, can also be coated with solvent glue, coating or extrusion method can be applied to the production of extruded composite heat sealing film BOPP. The film is widely used in bread, clothing, footwear and other packaging, and cigarettes, books cover packaging. The tear strength of BOPP film increases after stretching, but the secondary tearing strength is very low. Therefore, no cut can be left at the ends of the BOPP film, otherwise the BOPP film is easy to tear when printed and compounded. BOPP coated self-adhesive, we can produce our commonly used sealing tape, tape sealing tape, is a larger amount of BOPP market.

- Q: I saw a lot of different sizes of sealing tape on the Internet. Some are very thick and some are thin. Will the thickness of the same number be the same in the same number of yards? Some 100Y have around 1.5cm of the flesh, but some 100Y only about 0.7cm of the flesh, what is this possible? Or is it true or false? Ask the personage inside course of study to help solve!

- 100 yards, 150 yards, can be found everywhere! To do adhesive tape, we must find good faith partners! Professional to undertake all kinds of sealing tape production and wholesale

- Q: Can packaging tape be used for sealing plastic toys?

- Yes, packaging tape can be used for sealing plastic toys. Packaging tape is designed to be strong and adhesive, making it ideal for securing and sealing various types of materials, including plastic. It can effectively hold together the different parts of a plastic toy and provide a secure seal, ensuring that the toy remains intact. However, it is important to note that packaging tape may not be as aesthetically pleasing as other specialized tapes designed specifically for toy packaging, such as clear tape or decorative washi tape.

- Q: What are the considerations for using packaging tape on glossy surfaces?

- When it comes to using packaging tape on glossy surfaces, it's important to keep a few key things in mind. First and foremost, the smoothness and slickness of the glossy surface can affect how well the tape sticks. The glossy finish creates a barrier that can make it difficult for the tape to adhere securely. That's why it's crucial to make sure the surface is clean and free from any dirt, oils, or residue that could prevent the tape from sticking properly. Choosing the right type of packaging tape is also important. Opting for a tape specifically designed for glossy surfaces, like high tack or acrylic adhesive tapes, can provide better adhesion and last longer. These tapes are specially formulated to stick well to smooth surfaces and create stronger bonds compared to regular packaging tape. It's also a good idea to test the tape on a small, inconspicuous area of the glossy surface before applying it everywhere. This will let you see how well the tape sticks and ensure that it doesn't leave any residue or damage the glossy finish when you remove it. Temperature and environmental conditions should also be taken into consideration. Extreme heat or cold can affect how well the tape performs on glossy surfaces. For example, high temperatures can cause the adhesive to soften, leading to the tape failing, while cold temperatures can make the tape more brittle and prone to peeling. Lastly, it's crucial to handle the glossy surface with care to avoid leaving fingerprints, smudges, or scratches that could detract from its appearance. Wearing gloves or using protective films can help prevent these issues. By keeping these factors in mind, you can enhance the effectiveness and reliability of packaging tape on glossy surfaces, ensuring that your packages are securely sealed without compromising the glossy finish's aesthetic appeal.

1. Manufacturer Overview

| Location | Dongguan, China |

| Year Established | 2011 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | 30.00% North America 10.00% South America 20.00% Eastern Europe 20.00% Northern Europe 10.00% Western Europe 10.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangzhou Port |

| Export Percentage | 10% - 20% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 1000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | bopp tape, PE foam tape, EVA foam tape, cloth tape, masking tape, PET tape, kraft paper tape |

| Product Price Range | High; Average |

Send your message to us

High Quality Fiberglass Tape FGT-200 for Heat Machine Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1x20' FCL roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords