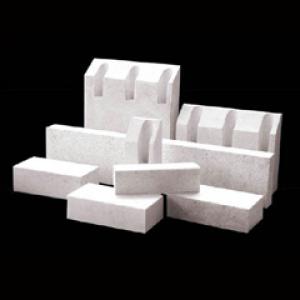

High Quality Corundum Brick - Purity Corundum Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | High Purity Corundum |

| SiO2 Content (%): | 0.2% | Al2O3 Content (%): | 99% | MgO Content (%): | -- |

| CaO Content (%): | -- | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | -- |

| SiC Content (%): | -- | Model Number: | CB | Brand Name: | LIRR |

| Name: | High Purity Corundum refractory bricks | Company: | Sinosteel Luoyang Institute of Refractories Research Co., Ltd. | Experience: | 51 years |

| Type: | R&D- Production-Sales/Manufacture | Certification: | ISO,CNAB,IAF | Main markets: | India,South Korea,Denmark, Russia, Europe, the United States |

| Packaging: | Fumigated pallet 2 Four bricks in carton, separated by foam board | Model: | CMB-70,CMB-80,CMB-90,CB-99 | CCS,MPa: | 70 |

| Long term service temp.,℃: | 1700 |

Packaging & Delivery

| Packaging Details: | 1 Fumigated pallet 2 A stable stack of bricks 3 Lables on two opposite faces 4 Card edges 5 Steel or nylon bands 6 Plastic wrap 7 Overall dimension:1.0*1.0*1.0m (Routine) 8 Gross weight:1.2-1.6MT (Routine) |

| Delivery Detail: | Based on order |

Specifications

Corundum series with high density, good mechanical property, stable chemical property, maily used in chemical, ceramic industry.

Product Description

1. High purity corundum bricks, which is characterized by good mechanical property at high temperature and good chemical stability,

2. Is widely used in oil gas gasifier, ethylene-generated furnace, and ammonia decomposing furnace in petrochemical industry, carbon black reactor in chemical industry, and high temperature kilns in refractories and ceramics industry.

3. It has gained the Third Prize of Science & Technology Progress from Sinopec and the former Ministry of Metallurgy Industry.

4. The brick has been used in the thermal equipment of domestric made or imported. It has been exported and used in German Texaco gasifier with good performance.

Physical and chemical index

| Item | Corundum Mullite Products | Corundum product | |||

| CMB-70 | CMB-80 | CMB-90 | CB-99 | ||

| Bulk density,g/cm3 | 2.5 | 2.6 | 2.8 | 3.15 | |

| Apparent porosity,% | 19 | 19 | 19 | 18 | |

| CCS,MPa | 60 | 70 | 70 | 70 | |

| Refractoriness under load,℃(0.2MPa,0.6%) | -- | -- | 1700 | 1700 | |

| Long term service temp.,℃ | -- | -- | 1700 | 1800 | |

| Linear change on heating,(1600℃×3h) | -- | -- | ±0.3 | ±0.3 | |

| Chemical composition,% | Al2O3 | 68 | 78 | 88 | 99 |

| SiO2 | -- | -- | -- | 0.2 | |

| Fe2O3 | 0.4 | 0.3 | 0.3 | 0.15 | |

Our Services

♥ Research of application basis, new technical process and new technology, development of new product, and technical consultation.

♥ Optimum solution and product supply of refractories for high temperature industries, such as iron&steel, non-ferrous, petrochemical and building materials.

♥ Engineering design, contract and consult for refractories, and civil architecture design.

♥ Research,development, manufacture and sale of superhard materials.

♥ R&D, manufacture and sale of special packing materials for export.

♥ Inspection,supervision and arbitration of refractories.

♥ Consultation and services in refractories information.

♥ Training and cultivation of high-level talents in refractories profession.

- Q: How much is a thermal brick?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: What is the main component of corundum?

- Corundum is the main component of Al2O3, often containing trace impurities such as Cr, Ti, Fe, V and so on.

- Q: What material is used in an iron smelting furnace?

- In fact, refractory refractory ah is special ceramic frequently used AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials.

- Q: What's the jade stove for?

- Corundum furnace for corundum smelting furnace, usually electric arc furnace for smelting dense corundum, corundum, white corundum, zirconia corundum, magnesia, magnesium aluminum spinel and fused refractory materials, professional design, Xi'an Xinda furnace engineering limited liability company manufacturing corundum furnace.

- Q: Which is good, glazed brick and whole cast glazed brick?

- Vitreous tile is all ceramic tile, the material is hard, strong wear resistance, smooth finish is very good, in general, looks very bright. Microcrystalline brick, corundum brick Market said, they really mean bohuazhuan. Because of its low water absorption and high strength and hardness, glazed tile has been widely used. Many hotels, shopping malls and office space are widely used glass tile.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: What is the hardness of corundum refractory bricks?

- Such as zirconium corundum refractory brick, chrome corundum refractory titanium corundum refractory brick.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- Refractory brick is non-metallic materials can be classified according to a kind of inorganic material, high aluminum brick, clay brick, magnesia brick, corundum brick, mullite bricks, silicon carbide materials such as brick, high alumina brick is used as a relatively wide range of products in accordance with the refractory brick high alumina refractory materials by high aluminum brick is generally divided into Al2O3 content three: I - II - >75% Al2O3 content; the content of Al2O3 is 60 ~ 75%; III - Al2O3 content from 48 to 60%.

- Q: What is the difference between corundum and high alumina?

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

Send your message to us

High Quality Corundum Brick - Purity Corundum Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords