High Quality Automatic Flexo Printing Machine FP5-480

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 Days/1 Set set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

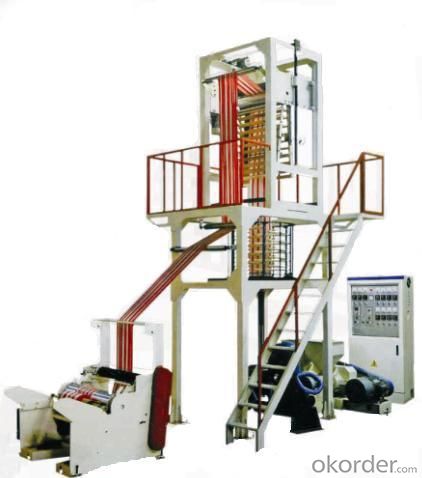

General Information High Quality Automatic Flexo Printing Machine FP5-480

Features:

1.Adopting anilox roller to spread ink.

2.Unwinding and rewinding processes are controlled by magnetic powder brake and clutch (or optional automatic tension controller made in Japan).

3.Each printing unit adopts 360°registration adjustment.

4.Each printing unit is equipped with IR (infrared) drier.

5.The rubber roller can break away automatically while the machine stops working or runs at a low speed, so as to prevent ink from drying.

6.The main motor adopts stepless speed regulation control with frequency conversion.

7.This machine can once complete unwinding, printing, varnishing (UV), IR drying, laminating and rewinding.

Technical Data High Quality Automatic Flexo Printing Machine FP5-480

Type: FP5-480

Max. Printing Width (mm): 450

MiinOrder: 1set

Package: Package wooden carton

Max. Web Width (mm): 480

Printing Color: 5

Max. Printing Speed (m/min): 60

Max. Unwinding Diameter (mm): 800

Max. Rewinding Diameter (mm): 750

Printing Girth (mm): 175~580

Precision of Chromatography (mm): ±0.1

Dimension(L x W x H) (mm): 2300 x 1260 x 2700

Machine Weight (kg): 2400

Packing of High Quality Automatic Flexo Printing Machine FP5-480

Packed with wooden carton of customized size and then placed on the pallet.

Storage Of High Quality Automatic Flexo Printing Machine FP5-480

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Remarks of High Quality Automatic Flexo Printing Machine FP5-480

Due to machine development, above information may be changed at any time without prior notice. The actual specifications are according to the agreement between buyer and seller.

Service of High Quality Automatic Flexo Printing Machine FP5-480

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

- Q: What is the general packing cost of beer beverage packaging?

- In addition, according to the product's own conditions to set, the packaging machine prices are generally in the range of 3-5 yuan

- Q: What are the main functions of packaging machinery?

- In order to meet the requirements of many customers, our company has learned from all aspects of the role of packaging machinery and equipment, so that we need customers for reference

- Q: What are the main plastic forming processes?

- 3. cold pressing molding. Cold pressing molding is also called cold pressing sintering molding. The difference between the cold press molding and the ordinary compression molding is that the material is pressurized and molded at room temperature. The mold after release can be heated or cured by chemical action. This method is used in the forming of polytetrafluoroethylene and some high temperature resistant plastics (such as polyimide, etc.). The general process is three steps of billet sintering cooling.4. transfer molding. Transfer molding is a molding process for thermosetting plastics. When molding, the mold is heated and softened in the heating chamber and then pressed into the mold cavity where it has been heated. According to the different types of transfer molding equipment form: trap type; the tank; the piston.The requirement of plastic molding for transfer molding is that the plastic should have a greater fluidity before reaching the curing temperature, and the curing rate must be faster at the curing temperature. Phenol, melamine, formaldehyde and epoxy resins can meet this requirement.Transfer molding has the following advantages: less waste edge products, can reduce the processing quantity; second molding with fine or brittle insert and perforation of the products, and can keep the insert and the hole position is correct; the product performance is uniform, accurate size, high quality; the mould wear small. The disadvantage is that the manufacturing cost is high compression mold die; the plastic loss; the fiber reinforced plastics for fiber orientation and anisotropy; and around the insert around the plastic, sometimes due to melting is not strong and make the products according to the strength reduction.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- Is it settled?. Not really! It is not recommended to use torque as parameter control here. This is a tricky amount of control. And easy to fluctuate, prone to misoperation

- Q: What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q: Whether you can press paper plastic molding after PET

- Another hot pressing mould pressing needs, blister sealing machine uses a plastic bakelite mold mold, high frequency plastic welding machine is used Aluminum Alloy mold. The size of the mold needs to be determined by blister.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- If these are good, and then talk about the price, always a penny goods, this side, quick packaging machine is not bad,

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- Because the packaging machinery is divided into many types, so many species also have different models, basically need to use packaging products requires packaging machinery, if not to fine some, it is necessary to sort of packaging machinery, slowly down. Packaging machinery is not required to use a certain scale, packaging machinery as well as automatic, semi-automatic, manual distinction. Most small workshops, or small factories, are semi automated or manual. If some of the larger factories will use automatic, or even a whole production line to complete automated packaging.

- Q: What are the packaging machines that use temperature control watches?

- Such as shrink machine, vertical packaging machine, pillow type packaging machine, continuous sealing machine,

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 25.00% North America 15.00% South America 15.00% Eastern Europe 5.00% Southeast Asia 10.00% Northern Europe 15.00% South Asia 5.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 10% - 45% |

| No.of Employees in Trade Department | 17-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 3,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | twister, packing machine, |

| Product Price Range | High; Average |

Send your message to us

High Quality Automatic Flexo Printing Machine FP5-480

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 Days/1 Set set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords