High Quality Automatic Flexo Printing Machine FP5-320

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 Days/1 Set set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

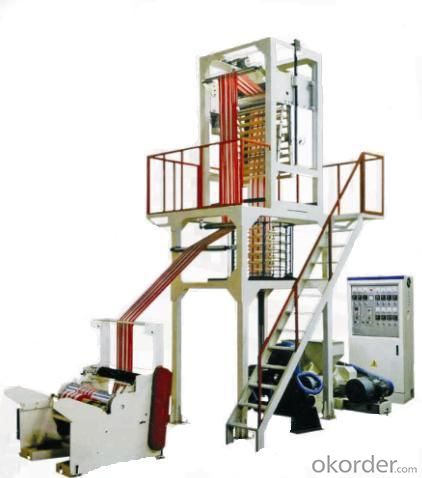

General Information High Quality Automatic Flexo Printing Machine FP5-320

Features:

1.Adopting anilox roller to spread ink.

2.Unwinding and rewinding processes are controlled by magnetic powder brake and clutch (or optional automatic tension controller made in Japan).

3.Each printing unit adopts 360°registration adjustment.

4.Each printing unit is equipped with IR (infrared) drier.

5.The rubber roller can break away automatically while the machine stops working or runs at a low speed, so as to prevent ink from drying.

6.The main motor adopts stepless speed regulation control with frequency conversion.

7.This machine can once complete unwinding, printing, varnishing (UV), IR drying, laminating and rewinding.

Technical Data High Quality Automatic Flexo Printing Machine FP5-320

Max. Printing Width (mm): 310

Max. Web Width (mm): 320

Printing Color: 5

Max. Printing Speed (m/min): 60

Max. Unwinding Diameter (mm): 600

Max. Rewinding Diameter (mm):550

Printing Girth (mm): 175~380

Precision of Chromatography (mm): ±0.1

Dimension(L x W x H) (mm):2100 x 1100 x 2600 mm

Machine Weight (kg): 2200

MiinOrder: 1set

Package: Package wooden carton

Packing of High Quality Automatic Flexo Printing Machine FP5-320

Packed with wooden carton of customized size and then placed on the pallet.

Storage Of High Quality Automatic Flexo Printing Machine FP5-320

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Remarks of High Quality Automatic Flexo Printing Machine FP5-320

Due to machine development, above information may be changed at any time without prior notice. The actual specifications are according to the agreement between buyer and seller.

Service of High Quality Automatic Flexo Printing Machine FP5-320

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

- Q: What is the design basis of automated packaging?! Just for today!

- Increase productivity and reduce process costGerman packaging machinery, especially beverages, beer filling machinery and food packaging machinery, with high speed, complete sets, high degree of automation and good reliability and so on. Beverage filling speed up to 1200 bottles / D, when the cigarette packaging 12000 / min.. Increasing the speed of the machine is a complex problem. The faster the piece production cost is, the higher the use area of the workshop is. In addition, the speed of the motor is limited, so do not think how fast, how fast. In general, the speed increase by 15%, 20%, will lead to a series of complex problems. In addition to increasing the speed, the productivity can be solved from other channels:1. continuous or long work. Packaging machinery works a batch type and continuous type, design, design should strive for continuous work, also can improve the productivity; one device may also have multiple production lines, the production of the same product or several different products, but must improve the reliability.2. reduce scrap rate and provide fault analysis system. The loss of waste to production is enormous, not only product loss, but also material loss. So try to force to reduce the rejection rate; packaging machinery sale should also provide maintenance services for the fault analysis system, the modal analysis is carried out to find fault, or through the Inter network for remote diagnosis, the maximum to meet customer needs. In the future, the packaging machinery will be further intelligent, that is, the equipment itself to find fault, to solve their own failure, to reduce waste rate and failure rate, so that the normal productivity can be improved.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- Hello, in recent years, Chinese packaging industry, although the annual growth rate ranked in the traditional industry for the first time, but in line with the international market, to accelerate the development of packaging technology, make its development to the economic, efficient, multi-functional direction. According to the development plan of Chinese national economy and to realize well-off life level, this year a few years for the packaging industry, the food industry to provide equipment for 100 billion yuan to 200 billion yuan, 80 billion yuan to 100 billion yuan to provide equipment for the "vegetable basket", this is a good opportunity for development of enterprises. At the same time, I learned from the relevant ministries, "95" period, will invest 10 billion yuan in the packaging industry to support and transform large and medium-sized packaging enterprises.

- Q: What are the packing machines?

- Heat shrink packaging machine, mask packaging machine, pillow type packaging machine, food packaging machine, I suggest you can go to see

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- This situation is best to find after sale processing, you have difficulty adjusting normal

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- 10 bags were randomly extracted from each of them, and the actual quality was measured as follows: (unit G)A: 501500503506504506, 500498497495B: 503504502498499501, 505497502499

- Q: What are the main functions of packaging machinery and equipment?

- Such as cleaning, stacking and disassembly. In addition, also includes the measurement or the package seal etc.

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

- Q: What is a packaging machine?

- Meet the needs of mass production and meet the requirements of clean sanitationUsually some non-standard equipment, the common is pneumatic and simple combination of electrical components, to meet the requirements of factory automation

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Mechanical sales are nothing more than two points: first, equipment aging, need to update; two, equipment efficiency is low, need to improve. You don't know anything about the customer. Come up and sell the product. If you are a customer, I don't think you have the patience to listen

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 25.00% North America 15.00% South America 15.00% Eastern Europe 5.00% Southeast Asia 10.00% Northern Europe 15.00% South Asia 5.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 10% - 45% |

| No.of Employees in Trade Department | 17-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 3,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | twister, packing machine, |

| Product Price Range | High; Average |

Send your message to us

High Quality Automatic Flexo Printing Machine FP5-320

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 Days/1 Set set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords