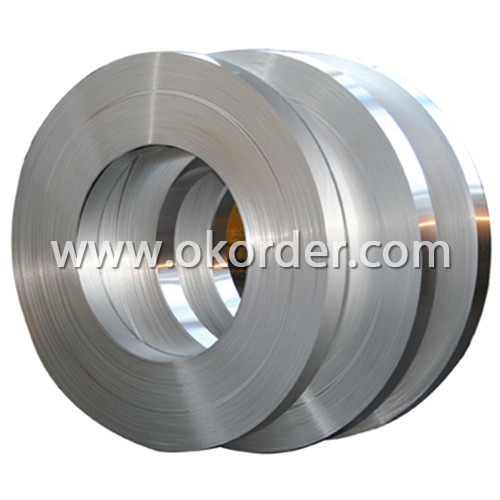

High Quality Aluminum Diamond Plate Strips AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of High Quality Aluminum Strips AA3003

Alloy Number | AA3003 |

Temper | Temper H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness | 0.10-500mm |

Diameter | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of High Quality Aluminum Strips AA3003

Aluminum strips are widely used for PS printed materials substrate, building decoration materials, stamping products, building mirror materials, nameplate, insulation materials, aluminum plastic composite material, capacitor strip, transformer strip, welding parts, heat exchanger, clock surface and disk, kitchen utensils, reflecting apparatus etc.

3. Packaging & Delivery of High Quality Aluminum Strips AA3003

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of High Quality Aluminum Strips AA3003

Rolling--Annealing--Slitting—Sawing, Cut-To-Length, Shearing

- Q: Is there any risk associated with the use of aluminum strips for roofing and siding purposes?

- <p>While aluminum strips are generally safe for roofing and siding, there are a few concerns to consider. Aluminum can expand and contract with temperature changes, which may lead to buckling or warping over time. Additionally, it is a good conductor of heat and electricity, so it may not provide the best insulation or protection against lightning strikes. Aluminum is also prone to denting and can be noisy in heavy rain or hail. However, it is lightweight, durable, and resistant to corrosion, making it a popular choice for many homeowners. Proper installation and maintenance are crucial to minimize these risks.</p>

- Q: Is it possible to use aluminum strips as a material for roofing purposes?

- <p>Yes, aluminum strips can be used for roofing. They are known for their durability, corrosion resistance, and lightweight properties, making them a popular choice for metal roofing. Aluminum roofing strips are low maintenance, energy-efficient, and can be recycled, offering environmental benefits. They are also resistant to harsh weather conditions and can last for several decades with proper installation and care.</p>

- Q: Is it possible to construct awnings or shelters using aluminum strips?

- <p>Yes, you can use aluminum strips to make awnings or shelters. Aluminum is a popular choice due to its lightweight, corrosion resistance, and strength. It can be bent and shaped easily to create the desired structure. However, it's important to consider the thickness and grade of aluminum to ensure it can withstand the weight and environmental conditions it will be subjected to. Proper support and reinforcement should also be included in the design to maintain stability and durability.</p>

- Q: Is it possible to utilize recycled aluminum in a project as an alternative to new raw materials?

- <p>Yes, you can use recycled aluminum in your project instead of new raw materials. Recycled aluminum is not only more environmentally friendly but also often more cost-effective. It requires significantly less energy to produce compared to new aluminum, reducing carbon emissions. Additionally, using recycled aluminum can help conserve natural resources and reduce waste in landfills. However, it's important to consider the quality and purity of the recycled material to ensure it meets the specifications required for your project.</p>

- Q: What are the safety standards or guidelines that should be followed when using aluminum strips?

- <p>Yes, there are safety standards for using aluminum strips. These include ensuring that the aluminum is of the correct grade for its intended use, following guidelines for handling and storage to prevent contamination or damage, and adhering to regulations regarding worker safety, such as wearing appropriate personal protective equipment. Additionally, it's important to comply with local and international standards like ASTM or ISO specifications for aluminum products. Proper ventilation should be maintained during processing to avoid inhalation of dust or fumes, and safety measures should be taken to prevent fires, as aluminum can be a fire hazard in certain conditions.</p>

- Q: This question asks about the ease of installation for aluminum strips.

- <p>Aluminum strips are generally easy to install. They are lightweight and can be cut to size with basic tools. Installation usually involves peeling off a protective backing and adhering the strip to a clean, dry surface. For best results, it's important to ensure the surface is free of dust and grease. Some types of aluminum strips may require additional fasteners or adhesive for a secure fit, but overall, the process is straightforward and can be done by most DIYers with a little patience and attention to detail.</p>

- Q: Explain the distinction between aluminum foil and aluminum strips, including their typical uses and characteristics.

- <p>Aluminum foil and aluminum strips are both made from aluminum but differ in thickness and application. Aluminum foil is very thin and flexible, typically used for food packaging, cooking, and insulation due to its light weight and barrier properties. It is often found in kitchens for wrapping food or lining baking sheets. Aluminum strips, on the other hand, are thicker and more rigid, used for structural purposes, such as in construction, automotive parts, or electrical components. They are also used in manufacturing for creating more durable and robust products. The thickness and flexibility of aluminum strips make them suitable for applications requiring strength and shape retention.</p>

- Q: Is it feasible to recycle aluminum strips?

- <p>Yes, aluminum strips can be recycled easily. Aluminum is one of the most recycled materials due to its lightweight, high strength, and the energy efficiency of the recycling process. The recycling of aluminum saves up to 95% of the energy needed to produce new aluminum from raw materials. Aluminum recycling is also beneficial as it reduces waste in landfills and conserves natural resources. The process involves melting the aluminum, which is much less energy-intensive than mining and refining bauxite. Recycled aluminum is used in various products, from cans to car parts, demonstrating its versatility and the ease of recycling.</p>

- Q: What factors should be considered to determine if an aluminum strip is suitable for a specific application?

- <p>To determine if a certain type of aluminum strip is suitable for your application, consider the following factors: mechanical properties such as strength and ductility, corrosion resistance, thermal conductivity, and electrical conductivity. Assess the strip's dimensional tolerances and surface finish to ensure they meet your requirements. Check if the strip's formability and weldability align with your manufacturing processes. Also, consider the strip's weight and cost-effectiveness. It's advisable to consult with a material scientist or supplier who can provide specific recommendations based on your application's unique needs.</p>

- Q: This question asks for criteria to determine if an aluminum strip is still safe and effective for use.

- <p>To determine if your existing aluminum strip is still suitable for use, you should check for any visible signs of damage such as cracks, bends, or corrosion. Ensure that the strip is clean and free from any contaminants that might affect its performance. If the strip is part of a mechanical system, check its dimensions to ensure it hasn't warped or lost its shape. Additionally, consider the strip's age and the conditions it has been subjected to, as prolonged exposure to certain elements can degrade its properties. If you're unsure, consult the manufacturer's guidelines or have a professional assess the strip's integrity.</p>

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Aluminum Diamond Plate Strips AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords