China 400mm High Purity Graphite Electrode for Smelting Zinc

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

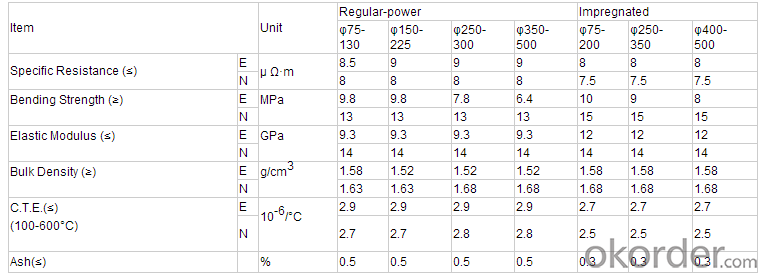

Graphite Electrodes Specifications

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Why should supercapacitors use graphite as electrode material?

- Because graphite material processing speed is fast, the cost is low.

- Q: Why use platinum ferroalloy instead of iron as electrode?

- Silica (Silica) is widely used in paint, ink, plastic, rubber and cosmetics, are often added to increase the performance of silica, such as oil absorption, extinction, strengthen the mechanical... Etc., and can reduce the cost of...

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- Indeed, the original battery electrode potential using two different electrodes, produce potential difference, so that the electron flow generated current. Graphite is used as an electrode because of its excellent electrical conductivity and stability

- Q: How long is the graphite electrode machining cycle?

- The dust produced in the processing of graphite electrode is relatively large, the possible intrusion to the machine tool guide screw and spindle, which requires a corresponding machining device of graphite graphite dust machine, sealing better, because the graphite toxic.

- Q: What's the purpose of the electrode material?When the electrolytic molten state of NaCl is said, what is the use of the graphite electrode and the iron electrode?

- 1. graphite (two kinds of EDM3 and EDM200)2. copperIn general, graphite electrode for extensive escape material (graphite texture loose, discharge energy is relatively large, removal of materials faster, but face flowers that roughness is relatively large

- Q: Do electroplating experiments, graphite as an electrode, graphite how to pre process to ensure that the coating will not fall, resulting in increased color of the solution

- Both of these will be a little bit absorbed, when plating, the anode and anode inside the syrup will run on the negative pole,

- Q: How can the graphite powder be processed into high quality carburizing agent? Thank you

- Basically, it can no longer be a "good" carburizing agent

- Q: Graphite electrode press device

- Graphite electrode is mainly in the petroleum coke and needle coke, coal tar pitch as binder, calcination, mixing, kneading, pressing, baking and graphitization, and made the processing machine, is a conductor in an electric arc furnace to form arc release electricity for heating and melting of the charge, according to the quality index level, can is divided into ordinary power, high power and ultra high power.

- Q: What kinds of carbon are there?

- Carbon products by product use can be divided into graphite electrode, carbon block, graphite anode, carbon materials, carbon electrode, carbon paste, electric, carbon fiber, special graphite, graphite heat exchanger etc..

- Q: How can I electroplate iron? I would like to use graphite as an electrode. Iron is plated on graphite with iron solution, so it can be processed into iron parts. I wonder if it can be done

- Iron plating can be, with 2 valence iron, but on the graphite joint force is good, it is difficult to say, electroplating is bad, peeling is also common. Relatively speaking, iron parts on nickel plating is relatively simple, also more applicable

Send your message to us

China 400mm High Purity Graphite Electrode for Smelting Zinc

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords