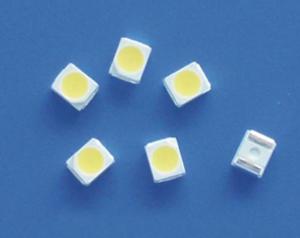

high luminance high efficiency 2835 CRI>90 light emitting diode LED

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 PCS

- Supply Capability:

- 1800000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Features & Benefits

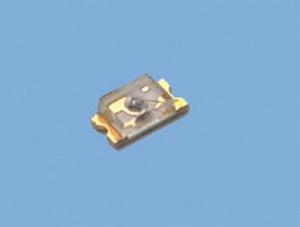

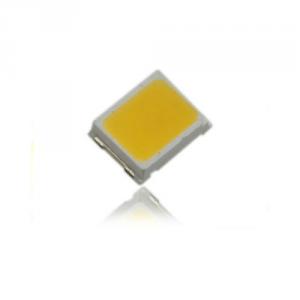

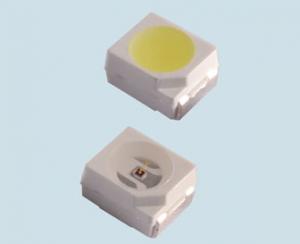

- Package: 2.8*3.5*0.65mm (Top view white LED)

- Emitted Color: White- Soldering methods: All SMT assembly methods

- Enables 3-, 4-, 5-step MacAdam ellipse kits

- Extremely wide viewing angle,standard form factor design flexibility

- The minimum luminous efficiency 110lm/w @60mA

2. Typical Application:

- Bulb

- Indoor & Outdoor sign board back light

- Advertising backlighting

- General use.

3. Precautions for use

3.1 Soldering

SMD LED encapsulation is very flexible, outside force easily demolish radiant surface and plastic, As soldering , Please handle with care!

a. With No-clean Flux, according to reflow soldering cure condition when soldering, Reflow soldering should not be done more than two times, simultaneity you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

b. Don’t process manual soldering except repair. Recommended to be soldered with 25W Anti-static iron, The temp. of the iron should be lower than 300℃ and soldering time should not be done more than three seconds, at the same time iron can’t touch radiant surface and plastic.

c. Don’t twist LED in course of manual soldering and experiment, Otherwise, the lights will not work possibly.

d. Please use the same BIN grade in one panel, and don’t mix the difference BIN grade in one panel when soldering. Otherwise, it will cause a serious uneven color problem.

e. Please control the sulfur content of solder paste and PCB.

f. Pb-free solder temp.-time profile as below:260℃Max.

3.2 Cleaning

a. Don’t be cleaned with ultrasonic. Recommended to be wiped with isopropyl alcohol or pure alcohol, wiping time should not be more than one minute. LED must be placed at room temperature for fifteen minutes before producing .you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

b. LED can’t be in contact with acetate、 trichloroethylene, acetone、 sulfur、 nitride、 acid、 alkali、 salt. These matters can destroy LED.

3.3 Sealing

a. Sealing glue can’t contain sulfur,because these matter can affect fluorescence powder poisoning.

b. When using normal sealing glue, recommended will be operated life for 168hrs under normal temperature.

3.4 Storage

a. Don’t open the moisture proof bag before ready to use the LEDs.

b. The LEDs should be kept at 30℃ or less and 60%RH or less before opening the package. The max. period before opening the package is 1 year.

c. After opening the package, the LEDs should be kept at 30-35%RH or less, and it should be used within 3 days. If the LEDs should be kept at 30-35%RH or more, and it should be used within 4 hours.

d. If the LEDs be kept over the conditions of 20%, baking is required before mounting. Baking condition as below: 70±5℃ for 12 hours for bulk goods, 105±5℃ for 1 hours for roll goods.

e. The environment have no acid、alkali、corrosive gas、intensively shake and high magnetic field.

3.5 Static

a. Static and Peak surge voltage can destroy LED, Avoiding Instantaneous voltage when turn on or turn off the lights.

b. Please wear Anti-static wrist band、Anti-static glove、Anti-static shoes in the course of operation, and the equipment must be grounded.

c. After LED is be destroyed, leakage current increase obviously, and it will be forward voltage falling or failure lamp in the case of low current.

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- Epoxy resins turn yellow during short wave irradiation or long periods of high temperature, so they are very short lived when applied to high power lighting. That's why the LED lighting market is dominated by silica gel.But because of the low price of epoxy resin (silica gel and not at a level), and storage, use and processing is superior to silica gel, so the low power LED and some optical components still use epoxy resin package.

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- The peak reflow temperature: 260 degrees or below this temperature. (surface temperature) 2 temperature over 210 DEG C required time: 30 seconds or less than this time. 3 reflow times: no more than two times. 4 after reflow, LED needs to be cooled to room temperature before contact with colloid.

- Q: LED light SMD LED package in what form, trouble you under the guidance of...

- The LED chip has bumps and is welded to the PCB board using FLIP CHIP to packaging technology.LED is English light emitting diode (light emitting diode) abbreviation, its basic structure is a electroluminescent semiconductor chip light emitting materials, with silver glue or glue curing to the bracket, connecting a chip and a circuit board and then with silver or gold, then sealed with epoxy resin around, to protect the internal core role finally, the installation shell, so the seismic performance of LED lamp is good. Field of application involves mobile phones, desk lamps, household appliances and other daily household electrical appliances and machinery production.

- Q: Is the forward voltage drop of the patch LED too large or too small?

- If you have to be good or bad, then I can say "small" to you,Some clients have strict requirements for this

- Q: Patch LED light does not flash, why?

- Hit the meter on the buzzer and measure the patch individually. If the flash is a patch, the light goes off.

- Q: What does patch LED light mean?

- The screen is divided into standard lamp and patch type, the light emitting diode lamp is inserted into the circuit board, and the patch is a patch welded on the circuit board. Two light sources are not the same. If only light, not so clear.

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- The same, stick pieces is an early product, stick pieces than patch mature, stick pieces of my lamp has almost can not see what changes for three years with only a patch of brightness, years have been feeling a lot of dark. I believe the quality will be good soon.

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Mold release agent is a functional substance between the mold and the finished product. The release agent is chemically resistant and is not soluble in contact with the chemical constituents of different resins (especially styrene and amines). Release agent also has heat and stress properties, not easy to decompose or wear; release agent bonded to the mold, and not transferred to the processed parts, without prejudice to painting or other two processing operations. Because of the rapid development of injection molding, extrusion, calendering, molding and laminating, the dosage of mould release agent is greatly improved.

- Q: What does "1210" mean in patch LED?

- At present, most manufacturers of SMD light strip used by 3528 and 5050, and 3535 and 5630 in the majority, there are many of the 3528 and 5050 and 3535, such as patch LED used in automotive lighting.

- Q: How do led patches measure good or bad?

- LED patch how to measure methods: use two meter meter test, red pen is positive, black pen negative, if there is "bee" sound is bad, if the light is good

Send your message to us

high luminance high efficiency 2835 CRI>90 light emitting diode LED

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 PCS

- Supply Capability:

- 1800000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches