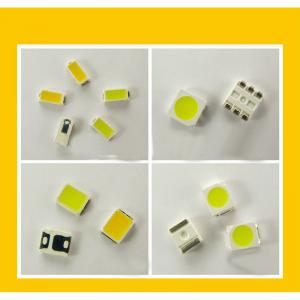

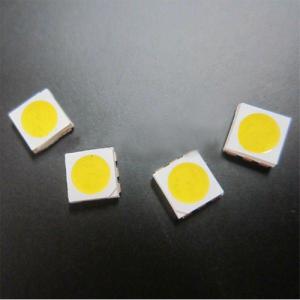

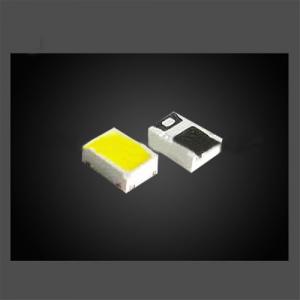

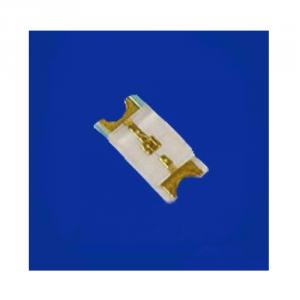

High Cri 5630 SMD LED (Ra95)

- Loading Port:

- Beijing

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

High Cri 5630 SMD LED (Ra95)

Features

-High CRI (Ra > 95, R9 > 90) to illuminate objects' true colors

-Full emission spectrum close to sunlight

-Half-power emission angle: 120°

-Internal structure: Aluminum base covered by silver

-Warm white and normal white available

-RoHS compliant

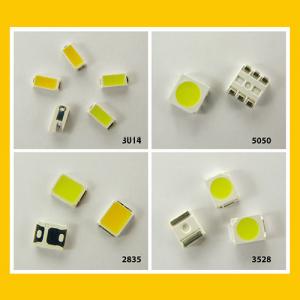

- 5.6mm*3.0mm surface-mount

Applications

Accent lighting products:

Photography lights

Museum and art gallery lighting

High-end shopping center

Exhibition or visitor center

Food display in supermarket

Hospitality or bar light

Hospital lighting

General indoor lighting

Electronic Products:

Display

Back-light unit

Medical equipment lighting

Optoelectronic Parameters (Ta=25°C)

Specification

Item | Symbol | Min | Typical | Max | Unit | Condition | |

Luminous flux | IV | 20 | ---- | 27 | lm | IF=120mA | |

HP Angle* | 2θ1/2 | ---- | 120 | ---- | Deg. | IF=120mA | |

Color Temp | Normal White | CCT | 4000 | ---- | 5000 | K | IF=120mA |

Warm White | CCT | 3000 | ---- | 4000 | K | IF=120mA | |

Forward voltage | VF | 3.3 | ---- | 3.5 | V | IF=120mA | |

Reverse current | IR | ---- | ---- | 5 | μA | VR=5V | |

Color Rendering | Ra | 95 | ---- | 98 | ---- | IF=120mA | |

Note

Half-power emission angle is calculated asθ1/2, where 2θ1/2 = θ1/2 + θ1/2

Our Service

With the continued development of LED technology and the expansion of LED applications, users are no longer only pursuing LED light efficiency and brightness. Instead, high CRI (Color Rendering Index) and tight binning (exact color temperature) are becoming two of the most important considerations for lighting designers, especially for those looking for accent lighting in order to show objects’ colorful appearance or create a certain atmosphere.

Advantages

1. R & D capabilities. We have our own LED packaging and LED phosphor research & production centers, by which we are able to develop our industry-leading technology to strictly control the light quality.

2. High color rendering. In addition to the CRI value (R1-R8 average), we focus on each R value. This is the only way that CRI be truly meaningful to evaluate the LED’s color rendering ability. Particularly, R9 (red) and R12 (blue) are difficult to improve, but meanwhile, indispensable in showing skin tones, foods, fabrics, etc.

3. Light efficiency. Most LEDs with claimed CRI 95 in the market have relative low luminous efficiency than normal LED. We are using the best LED chip and phosphors to keep our light efficiency competitive given CRI 95.

4. Excellent team. We have passionate members with expertise knowledge.

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- When making a batch of LED lights, the brightness values of various lights are in accordance with certain rules. Due to achieve a white balance, three RGB color brightness required by the ratio of 3:6:1, that is to say the blue light required brightness is very low.

- Q: What is the principle used in SMD LED lamp, should pay attention to what the problem?

- LED white is the light emitting diode, a PN junction to the most important use of SMD beads is the heat, according to the different manufacturer beads, glue package is not the same, should pay attention to pre baking time and temperature, the latter should pay attention to the patch temperature, the most important is the price, many manufacturers in order to cost savings, internal chip used is too small does not meet the standards, support steal frugal material, with iron, the failure cycle shortened, LED lamp can not reach the ideal effect. Again, the LED supply current must not exceed the rated value, which is an important factor in damage to lamps and lanterns

- Q: How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- More attention is paid to the lamp with waterproof and the installation of a solid in the outdoor installation, outdoor installation often adopts the mode of fixed card slot, need to cut and connected place, and indoor installation, just need another with waterproof glue, waterproof effect to consolidate the connection point.

- Q: What, in what way do I shunt the LED?

- LED lights are current driven, first of all, look at your LED's IF and VF values. How much power do you have?. Make sure the current is in line with the IF and the current limit can be achieved with resistors.

- Q: What is patch SMD-LED?

- This really do not know how to answer you, like a sheet of the same type of solder paste used to operate, it can be said that the plug-in is not, it is patch it!

- Q: What does patch LED light mean?

- Look, what's your product?. Some products have volume requirements, straight line will be relatively large, patches of small affixed to the circuit board does not occupy space, if only the light source, it may be an ordinary light bulb, as LED power saving.

- Q: Which is good for LED patch and LED bulb?

- Chip LEDLED patch lamp (SMD) is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.LED bulbThe light emitting diode, is capable of converting electrical energy into visible solid semiconductor devices, which can be directly converted into electricity to light; LED Large Electronic = Display, LED = large electronic display; Lupus erythematosus disseminatus, systemic lupus erythematosus, a chronic idiopathic autoimmune disease; LED lead the past and past participle, meaning "leadership, led the Russian Pulkovo Airport IATA code.

- Q: Patch LED features

- The principle of luminescence is that of cold luminescence, not by heating or discharging light, so the component life is about 50~100 times longer than that of tungsten filament bulb, and about one hundred thousand hours.

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- They differ in form and belong to the SMDLED category. Encapsulation uses liquid silicone and epoxy resins as well. The patches are basically made of epoxy resin. Relatively speaking, the amount of liquid silica should be relatively large.

- Q: SMD LED lamp working voltage?

- Voltage range of white LED lamp: 3.0-3.4VThe pressure drop of the red LED is 2.0--2.2VThe yellow light emitting diode has a pressure drop of 1.8 - 2.0VThe green light emitting diode has a pressure drop of 3 - 3.2VThe blue light emitting diode has a pressure drop of 3.0-3.4VSMD voltage is basically the same as double lead line. Current is generally 20~60mA, and some work current can exceed 100mA.

Send your message to us

High Cri 5630 SMD LED (Ra95)

- Loading Port:

- Beijing

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords