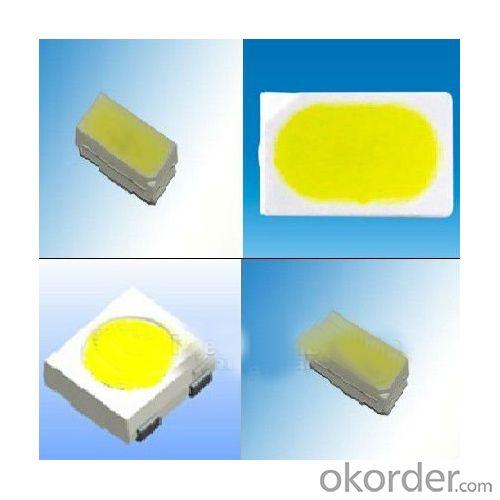

High Quality SMD 2835 Chip LED

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

| Model: | 3528-H0120 | Name: | 3528 SMD LED |

| Chip: | Taiwan Epistar | Input Volatge: | 3.0-3.2V |

| Color Temperature: | 2900-6500K | Luminous Flux: | 7-8lm |

| Warranty: | 2 Years | Life Span: | 50000hours |

Advantages

1.High brightness.

2.Small size .

3.Long lifespan .

4.Energy saving and environmental protection.

5.Light color pure .

6.Wide light emitting angle.

7.Silicone packaging .

8.Anti-UV capability .

9.Resistance high temperature .

10.Can be applied to a variety of harsh environments.

11.High consistency in light color, high cost-effective.

Application of SMD LED 3528

1) Indoor and outdoor displays .

2) Substitution of micro incandescent lamps.

3) Traffic lights.

4) Interior and exterior automotive lighting(e. G. Dashboard backlighting and brake lights .

5) Backlighting (LCD, cellular phones, switches, keys, displays, illuminated advertising)

6) LED tube, LED strip, LED bulb, LED spotlight and so on .

About us

We are a manufacturing and sales of LED light series products, Holy lighting has a well-trained team,including experienced technicians and salesman, .Continuous product innovation and reliable cooperation with our customers are the foundation of our development.

LED series:We specialize in LED Auto car light,SMD 3528/5050 LED,G4 bulb,LED Module strip,LED GU10/MR16/MR11/E27/E17/E14 light,Led tube & project infrastructure,etc. all of them prove that we can supply excellent quality and good service to you. Your OEM or ODM projects are welcomed.

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: 0603,0805,1206,3020,3528,5050,355 what is the current and voltage of these patch LED? Please give advice!

- The patch LED is also called SMD LED. Its principle of luminescence is to pass the current through the compound semiconductor. Through the combination of the electron and the hole, the excess energy will be released in the form of light to achieve the effect of luminescence.

- Q: LED light SMD LED package in what form, trouble you under the guidance of...

- There are 3 types of LED packages: inline LED, piranha LED, and surface mount LED

- Q: What, in what way do I shunt the LED?

- In series, the voltage is 20 times the rated voltage, in parallel, the voltage is rated voltage, but in tandem, a LED is broken, it is not bright, so it is recommended not to use it.

- Q: Patch LED light does not flash, why?

- There are three main reasons:1, the temperature is too high, resulting in LED lights, dead lights.2, do not do anti-static measures, electrostatic breakdown chip, resulting in damage to the LED light.3, the use of LED lamp quality is too bad, the purchase price reasonable LED lights

- Q: Patch LED beads can be bought in what place?

- Many LED packaging plants do patch LED, you can find the relevant manufacturers to contact, or go to the local electronic components market according to your needs

- Q: Patch LED market conditions

- Conventional monochrome SMD LED package sizes are 1206 (3215), 1004 (2510), 0805 (2012) and 0603 (1608). Chinese manufacturers can provide a minimum size of 0603, the thickness of only 0.3 mm. A smaller LED of 0402 (1005) is still in trial manufacture

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Mold release agent is a functional substance between the mold and the finished product. The release agent is chemically resistant and is not soluble in contact with the chemical constituents of different resins (especially styrene and amines). Release agent also has heat and stress properties, not easy to decompose or wear; release agent bonded to the mold, and not transferred to the processed parts, without prejudice to painting or other two processing operations. Because of the rapid development of injection molding, extrusion, calendering, molding and laminating, the dosage of mould release agent is greatly improved.

- Q: What does "1210" mean in patch LED?

- 1210 refers to the lamp specifications.LED common lamp specifications and parameters of patch0603, 0805, 1210, 3528, 5050 refers to the LED lamp belt, often used in light-emitting components ----LED size (English / Metric) name, for example, 0603 refers to the length of 0.06 inches, width of 0.03 inches. But note that the 3528 and 5050 units are metric

- Q: SMD LED lamp working voltage?

- Voltage range of white LED lamp: 3.0-3.4VThe pressure drop of the red LED is 2.0--2.2VThe yellow light emitting diode has a pressure drop of 1.8 - 2.0VThe green light emitting diode has a pressure drop of 3 - 3.2VThe blue light emitting diode has a pressure drop of 3.0-3.4VSMD voltage is basically the same as double lead line. Current is generally 20~60mA, and some work current can exceed 100mA.

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- Recommend to communicate with older employees, they will have a lot of welding experience

Send your message to us

High Quality SMD 2835 Chip LED

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords