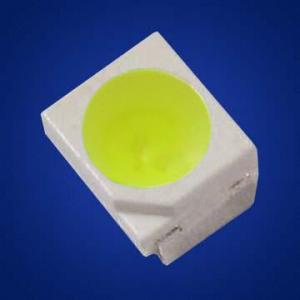

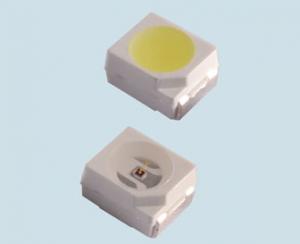

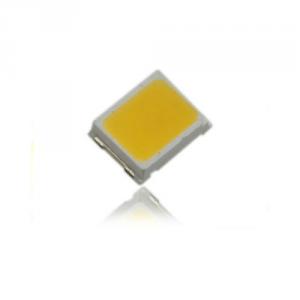

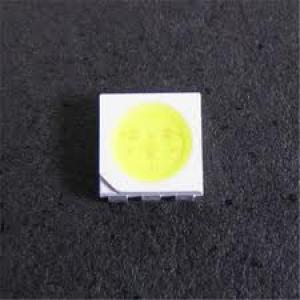

high luminance 3030 light emitting diode LED

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 180000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Features & Benefits

- Package: 3.0*3.0*0.60mm (Top view white LED)

- Power:1W(6V@150mA)

- Emitted Color: White

- CRI:Ra>80

- Saturated Red:R9>0

- Enables 3-, 4-, 5-step MacAdam ellipse kits

- Conforming to the ANSI standard

- Soldering methods: All SMT assembly methods

2. Typical Application:

- Bulb、Spotlight、Tube Lamp、Stage lamp

- Indoor & Outdoor sign board back light

- Advertising backlighting

- General use.

| Parameter | Symbol | Min. | Type | Max. | Unit | Condition |

| Forward Voltage | Vf | - | 6.2 | 6.6 | V |

IF=150mA |

| Luminous Flux | Φ | - | 130 | Lm | ||

| Color Rendering Index | Ra | 80 | - | - | ||

| Viewing Angle | 2θ1/2 | - | 120 | - | deg | |

| Saturated Red | R9 | 0 | - | - | ||

| Reverse Current | IR | - | - | 0.5 | μA | vr=10v |

3. Precautions for use

3.1 Soldering

SMD LED encapsulation is very flexible, outside force easily demolish radiant surface and plastic, As soldering , Please handle with care!

a. With No-clean Flux, according to reflow soldering cure condition when soldering, Reflow soldering should not be done more than two times, simultaneity you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

b. Don’t process manual soldering except repair. Recommended to be soldered with 25W Anti-static iron, The temp. of the iron should be lower than 300℃ and soldering time should not be done more than three seconds, at the same time iron can’t touch radiant surface and plastic.

c. Don’t twist LED in course of manual soldering and experiment, Otherwise, the lights will not work possibly.

d. Please use the same BIN grade in one panel, and don’t mix the difference BIN grade in one panel when soldering. Otherwise, it will cause a serious uneven color problem.

e. Please control the sulfur content of solder paste and PCB.

f. Pb-free solder temp.-time profile as below:260℃Max.

3.2 Cleaning

a. Don’t be cleaned with ultrasonic. Recommended to be wiped with isopropyl alcohol or pure alcohol, wiping time should not be more than one minute. LED must be placed at room temperature for fifteen minutes before producing .you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

b. LED can’t be in contact with acetate、trichloroethylene,acetone、sulfur、nitride、acid、alkali、salt. These matters can destroy LED.

3.3 Sealing

a. Sealing glue can’t contain sulfur,because these matter can affect fluorescence powder poisoning.

b. When using normal sealing glue, recommended will be operated life for 168hrs under normal temperature.

3.4 Storage

a. Don’t open the moisture proof bag before ready to use the LEDs.

b. The LEDs should be kept at 30℃ or less and 60%RH or less before opening the package. The max. period before opening the package is 1 year.

c. After opening the package, the LEDs should be kept at 30-35%RH or less, and it should be used within 3 days. If the LEDs should be kept at 30-35%RH or more, and it should be used within 4 hours.

d. If the LEDs be kept over the conditions of 20%, baking is required before mounting. Baking condition as below: 70±5℃ for 12 hours for bulk goods, 105±5℃ for 1 hours for roll goods.

e. The environment have no acid、alkali、corrosive gas、intensively shake and high magnetic field.

3.5 Static

a. Static and Peak surge voltage can destroy LED, Avoiding Instantaneous voltage when turn on or turn off the lights.

b. Please wear Anti-static wrist band、Anti-static glove、Anti-static shoes in the course of operation, and the equipment must be grounded.

c. After LED is be destroyed, leakage current increase obviously, and it will be forward voltage falling or failure lamp in the case of low current.

3.6 Test

a. Customer must apply the current limiting resistor in the circuit so as to drive the LEDs within the rated current. Otherwise slight voltage shift maybe will cause big current change and burn out will happen.

b. Also, caution should be taken not to overload the LEDs with instantaneous high voltage at the turning ON and OFF of the circuit.

c.The reverse voltage mustn’t exceed 5v when lighting on or testing the LED, otherwise, LEDs will be damaged.

- Q: What determines the brightness of the patch LED?

- The brightness is consistent over a short period of time, that is, only by considering current and voltage consistency.Long term brightness is consistent with the consideration of the spacing and heat dissipation of different circuits. Uneven heat can also affect brightness.

- Q: 0603,0805,1206,3020,3528,5050,355 what is the current and voltage of these patch LED? Please give advice!

- SMD LED specification:(1) metal stent type: 0402, 0603, 0805, 1206, 3mm, 5mm, 6mm, 8mm, 10mm and so on.(2) metal support (commonly known as small butterfly) type: 2mm, 3mm and so on.(3) TOP LED (white shell) type: 1208 (30*20), 1311 (35*28), 1312 (35*32), 2220 (55*50) and so on(4) side light LED:0905 (22*12), 1105 (28*12) 1605 (40*14) and so on.

- Q: How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- Installed indoors, you can directly tear off the stickers on the 3M double-sided adhesive surface, and then fix the light bar where it needs to be installed. Just press it with your hands.

- Q: What, in what way do I shunt the LED?

- The voltage problem is determined by the size of your POWER SUPPLY, according to Ohm's Law: the series voltage is accumulated and the shunt voltage is the same.

- Q: Patch LED beads can be bought in what place?

- SMD LED lamp is now very popular, mainly because of long service life, but also rarely appear dead lights or dark, but there are many defects exist

- Q: Which is good for LED patch and LED bulb?

- The LED patch is the same as the LED bulbLED (light emitting diode) patch (package)The LED patch (SMD) is made of FPC circuit board, LED and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.LED bulbWith the LED patch or LED plug-in LED (light emitting diode), series or parallel, driving power supply, making a combined shell lampshade capable of converting electrical energy into visible solid semiconductor devices, which can be directly converted into electricity to light.

- Q: What are the storage requirements of SMT patch LED (LED)?

- Moisture-proof packing- anti SMD LED in the transport and storage of moisture absorption, SMD LED shall be placed in sealed moisture-proof bag, inside put damp proof agent for protection, and placed the humidity humidity SMD display card packaging bag.

- Q: The quality of the LED patch module

- Luminous efficiency。 The LM value per watt is called luminous efficiency. This is an important criterion for judging whether LED is energy-saving or not. The incandescent lamp is about 14.4LM/W, the fluorescent lamp is about 51LM/W, the neon lamp is 43LM/W or so, and the LED is up to 150LM/W at present, but most of the LED light effects in our country are in 60~100LM/W. It should be noted that only the white light can achieve such high luminous efficiency in LED, and that red, yellow and blue are generally relatively low (mainly related to human visual definition). But compared with neon light, there is no heavy metal pollution, easy to maintain.

- Q: What does "1210" mean in patch LED?

- At present, most manufacturers of SMD light strip used by 3528 and 5050, and 3535 and 5630 in the majority, there are many of the 3528 and 5050 and 3535, such as patch LED used in automotive lighting.

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- When soldering, the temperature is best to be lower, and the average welding temperature is about 360. That's enough, because the melting temperature of the tin wire is about 220 degrees, so if it is allowed, the temperature can be reduced as low as possible.

Send your message to us

high luminance 3030 light emitting diode LED

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 180000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords