High Light Monochrome Film for Decorative

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of High Light Monochrome Decorative Film:

High Light Monochrome Decorative Film for Decoration covered by vacuum/membrane press/laminating machine on the surface of various boards, such as MDF, veneer boards, flake boards, fiberboards, block boards and other materials of high-pressure floor slabs, asbestos boards, slates, aluminum and plastic profiles. High Light Monochrome Decorative Films are widely used for indoor decoration and furniture making industry.

2.Main Features of the High Light Monochrome Decorative Film:

Different models and various kinds of style

Sparkle silver and wood grains are available

Easy cleaning

Eco Friendly

Exquisite color, high saturation, environmentally-friendly, waterproof, unfading,acid and alkali resistant.

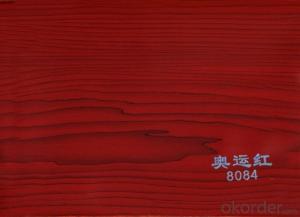

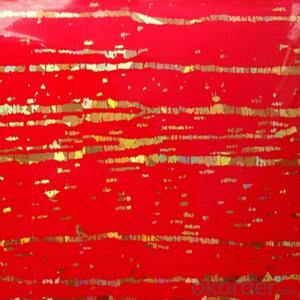

3. High Light Monochrome Decorative Film Images:

4. High Light Monochrome Decorative Film Specification:

Thickness from 0.12mm to 0.60mm

Length: 100-500m/roll

Width: 200-1,575mm

5. FAQ of High Light Monochrome Decorative Film:

We have organized several common questions for our clients, may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of PVC decorative sheet is a new kind of environmental protection material, it has strong sense of grain simulation, waterproof, acid and alkali resistant, fire from self quenching characteristics, because it will not fade, so the construction without paint, convenient operation, which shortens the construction period and reduce the cost, especially without paint pollution gas.

2) What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is original iPad coated with a protective film?

- No. There's almost nothing complimentary with original iPad.

- Q: How to remove the protective film on stainless steel elevator?

- Try to heat the film with electric hair drier before you peel it off!

- Q: What to do if there are some white dots on the protective film coated on high-light product?

- Please use protecive film of better quality. The foggy white dots may be generated because the glue reacts with the air.

- Q: The mirror protective film is what, how should the truth!

- The film mirrors the strange name, reflecting film is like a mirror, in outdoor use or have a certain reflection.

- Q: The way to distinguish acrylic glue from silica gel.

- The states of existence of acrylic glue and silica gel are different. Thus their effects are different.

- Q: The family has three or four months of baby, my mother let me tear up, said airtight, the mother-in-law said no, said is easy to dirty, how should I deal with?

- Some suggestions for the maintenance of mattresses:1. turn regularly. The new mattress during the first year of purchase, every 2 to 3 months, positive or negative, or around the corner to turn each other, so that the mattress spring force evenly, and then about once every six months can turn.2. keep clean. To do a good job bedding hygiene, sun drying. If the mattress stain, you can use toilet paper or cloth to suck moisture, not washed with water or detergent. Avoid lying in bed after sweating or after sweating, or using electrical appliances or smoking in bed.3., do not often sit on the edge of the bed, bed angle. Because the 4 corners of a mattress is the most fragile, long in the edge of the bed sit, easy to make the edge damage early spring.

- Q: What areas is protective film mainly used in?

- Protective film can be used on surface protection in fields as follows: metal products, coated metal products, profiles, electronic products, plastic products, scutcheons, automotive products and other products. The structure and material of protective film is highly demanded in Hualibao company to meet different needs in different fields of the customers.

- Q: How to change the screen of mobile phone screen?.

- (3) along the direction of the film gently pushing credit card or hard plastic sheet, film direction do gently pushing, the purpose of doing so is to ensure that no film produced in the process of pushing the bubble, while at the same time, while also observed fit part whether there is a bubble, once found on bubbles. Should gently lift, remove dust to continue after the operation, if completely good, then there are bubbles, remedy is not easy.5, completely paste flat, and slowly tear the surface of the second sub membrane. If the model screen is depressed, you can stick it with a strong adhesive glue.

- Q: How to remove the protective film of stainless steel?

- Blow the film using electric hair drier and then tear it off.

- Q: Adhere to the surface of metal material, tear the film after punching, so that the metal surface is free from scratch and the size is not affectedHow to distinguish and identify the quality of protective films from different manufacturers?.

- Adhere to the surface of metal material, tear the film after punching, so that the metal surface is free from scratch and the size is not affected

Send your message to us

High Light Monochrome Film for Decorative

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches