High Light Flash Film Uesed For Decorative

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of High Light Flash Decorative Film:

High Light Flash Decorative Film can be applied on flat panel or walls easily, and if you want to change, you can tear it easily without damage your wall. Our High Light Flash Decorative Film is very easy to install and eco friendly.Our High Light Flash Decorative Film can be used on Furniture, kitchen wall, bedroom, hotel etc. many fields.

2.Main Features of the High Light Flash Decorative Film:

Surface is smooth, exquisite

Water-proof, resistance to deformation

Environmental friendly

Different models and various kinds of style

Sparkle silver and wood grains are available

Easy cleaning

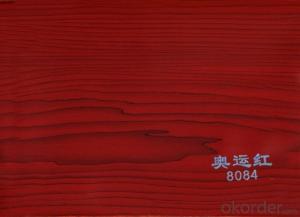

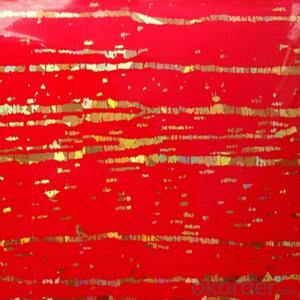

3. High Light Flash Decorative Film Images:

4. High Light Flash Decorative Film Specification:

Thickness : 0.10 - 0.50mm

Width : 1240/1260/1400 mm

Weight : 20-21 KGs / Carton

Length : Based on customer's requirement

5.FAQ of High Light Flash Decorative Film:

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of PVC decorative sheet is a new kind of environmental protection material, it has strong sense of grain simulation, waterproof, acid and alkali resistant, fire from self quenching characteristics, because it will not fade, so the construction without paint, convenient operation, which shortens the construction period and reduce the cost, especially without paint pollution gas.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What can the PET protective film be used for?

- PET protective film refers to protective film made from PET materials. The beverage bottles we often see are made from those PET materials. This kind of film can be used to protect the screens of mobile phones, cameras, etc. from scratching.

- Q: How to clean the aging protective film sticked to the steel door?

- Chemicals will damage the steel plate! 1. Scrubing the door using hot water with washing powder. 2. I don' t know what metarial the surface of the door is made from. Thus I don't know the film can be cleaned by knife. 3. Using chemical reagent: lacquer thinner which is sold everywhere. By the way, you can heat the film with lighter to make its edge curl, which will make it easy to tear the film off. It won't damage the steel plate.

- Q: Is the laptop monitor covered with protective film?

- We know that the LCD protective film factory configuration is a layer of plastic film, and the film, not only greatly affect the visual effects, reduce the permeability and have a lot of reflection, will affect the user's eye. In addition, the heat dissipation of the display is extremely unfavorable. The plastic film is not a good conductor of heat. The liquid crystal panel will heat up after a period of time, and touch the panel with the back of the hand. You can tell that the temperature is very high. If the surface is coated with a protective film with poor thermal conductivity, it virtually prevents the cooling of the liquid crystal and even shortens the effective life of the display.

- Q: How to remove the mobile phone protection film?

- Slowly should be able to get down, and the latter affixed to the film affixed to the tight, may not be easy to tear down, you can use a little alcohol, oh, so OK.

- Q: Does anyone know of a glue that sprays up to form a protective film?

- I was a technical director of a well-known enterprise with mature technical formulations, oily and water-based, most of which were used for PE protective films.. The following is a recipe note, and I hope it will help your company.

- Q: What's the reason why watermarks are easy to appear on protective film of high adhesion?

- NOTE: Standard protective film is anti-static. You can't feel it adhesive by hands. It's the only choice of high-class digital camera and digital vidicon. Some protective films on the market is very sticky because it's just a layer of plastic film coated with glue. There may be bubbles or watermarks on the screen after you cover it on the screen. The display effect will be very bad. And this kind of film is very difficult to remove. It's even more difficult to clean up the glue. Remember it: if you really cherish your cell phone, digital camera or digital vidicon,NEVER use this kind of film on it!

- Q: What are the requirements for PE protective films?

- The excellent mechanical properties: meet user requirements of tensile strength, elastic modulus and elongation etc..

- Q: Is it good or bad to put a protective film on the keyboard?

- To sum up, if you like beautiful keyboards, like to buy new keyboards, and typing needs comfort, don't use the film.

- Q: Is it necessary to tear off the protective film on surveillance camera?

- The image will be clearer if you tear off the film. But of course it won't affect too much if you do not.

- Q: What harm can the protective film on bottled water do?

- It's not harmful. It's separated from the water bottle. And there are national security standards to keep it under control.

Send your message to us

High Light Flash Film Uesed For Decorative

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches