Ceramic Fiber Module High Heat Insulation DZ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

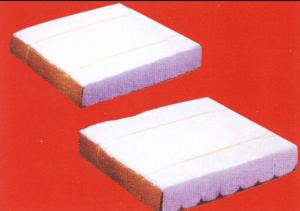

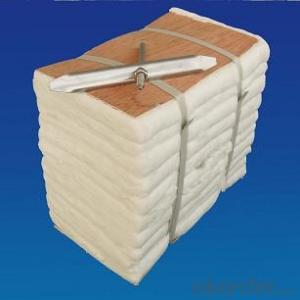

General Information of Ceramic Fiber Module

CMAX ceramic fiber Module is made from high quality Gao-Ling clay, high purity alumina and silica oxides by spun or blown process. It is asbestos free. Double-side needling provides Module with great tensile or handing strength for easy installation.

The products are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃,1100℃,1200℃ and 1350℃

Feature of Ceramic Fiber Module

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

High tensile strength

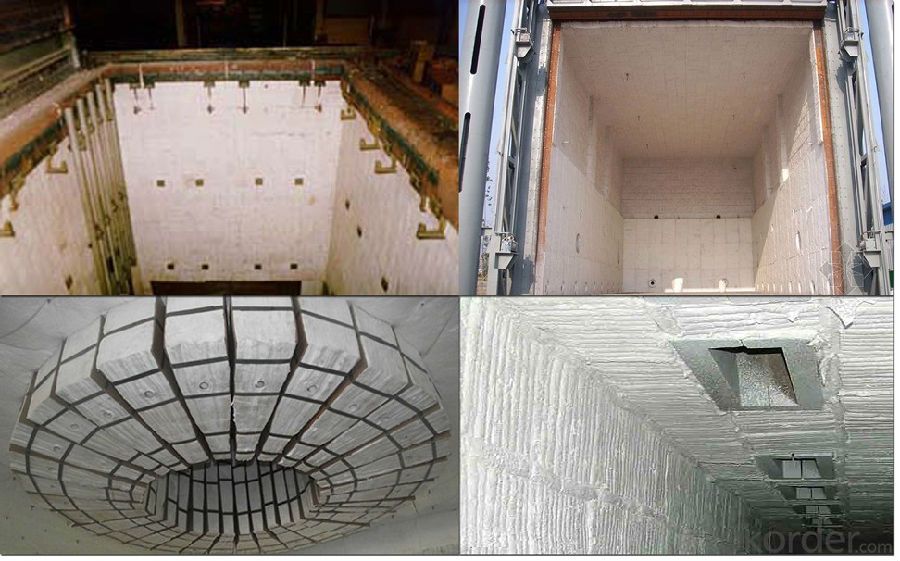

Application of Ceramic Fiber Module

Petrochemical process heater refractory fiber lining

Heat treating furnace or Intermittent(shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

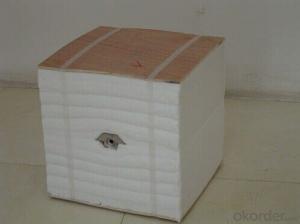

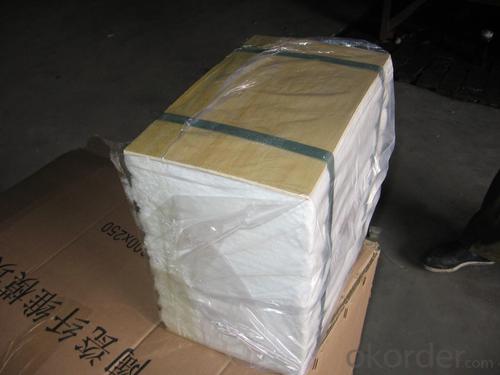

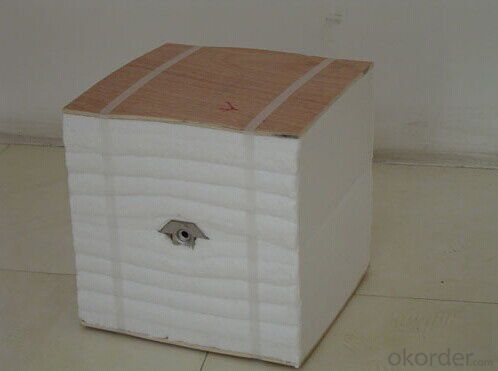

Picture of Ceramic Fiber Module

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Yes, only the machines require more special

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- Hot galvanizing furnace is usually burning natural gas to the new pot heating, natural gas heating will produce higher wind speed to 21m/s, so the hot galvanized furnace insulation materials have certain requirements. The hot galvanizing furnace before 2013 is usually made of refractory bricks for heat preservation, and the energy saving effect is common.

- Q: How to install refractory fiber?

- Good chemical stability; good thermal stability; excellent elasticity, ceramic fiber module is pre pressed state, in lining up after the expansion of ceramic fiber module to enable seamless lining, and can compensate for fiber lining contraction, in order to improve the insulation performance of fiber lining, the overall performance is good; excellent thermal stability and thermal shock resistance the ceramic fiber module; quick installation, and anchors set in the wall lining noodles, can reduce the anchor material requirements.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- Heat insulation material with low thermal conductivity of ceramic fiber products, but this insulation material is soft material, some aspects of the use of defects. In contrast, Tianjin solid microporous nano insulation board has lower thermal conductivity.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life, corrosion resistance, aluminum, zinc and other non-ferrous metal corrosion capacity; has a good low temperature and high temperature strength;

Send your message to us

Ceramic Fiber Module High Heat Insulation DZ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords