Raw Materials for High Density Oven Insulation Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Oven insulation board

1.Max Tem.:1800C

2.Density:300-700kg/m3

3.Size:Customized

High density oven insulation board

Oven insulation boardbelongs to wet vacuum suction filter molding, the loose cotton and organic

and inorganic binder.

The product has hard texture and excellent strength, anti erosion, easy processing cutting

The chemical properties of refractory fiber material stability, and light weight, good thermal

insulation effect,it is a multi-purpose product, which can be applied to the lining surface of heat resistant flame and high

temperature air directly impact.

High stability

Low thermal conductivity

Low thermal capacity

Resistance to thermal shock

Resistance to erosion

Easy to be processed and cut

High thickness precision and size precision

Exceptional ability to withstand flames and gas flows

Regular size of Oven insulation board :

LxW:600mmx400mm,1000mmx500mm,1000mmx600mm

Thickness:20-150mm

Epecial size:According to custoers' requirement

Packing:Carton or wooden box

Model | LEPE-1000 | LEPE-1260 | LEPE-1400 | LEPE-1600 | LEPE-1800 | |

Classification temperature | 1000°C | 1260°C | 1400°C | 1600°C | 1800°C | |

Density(kg/m3) | 300-700 | 300-700 | 300-700 | 300-700 | 300-700 | |

Reheating Linear Change (%) | (800°CX24h)<1 | (1050°CX24h)<1 | (1200°CX24h)<1 | (1500°CX24h)<1 | (1600°CX24h)<1 | |

Chemical Composition (%) | Al2O3 | 38 | 42 | 50 | 68 | 85 |

Al2O3+SiO2 | 96 | 98 | 99 | 99.5 | 99.8 | |

Fe2O3 | 0.2 | 0.2 | 0.2 | - | - | |

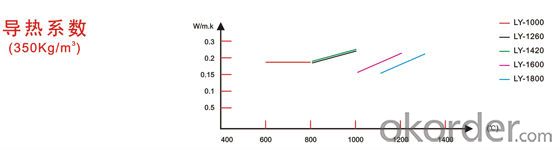

Thermal conductivity of Oven insulation board

- Q: What are the electrical fire protection materials?

- Electrical fire protection materials are the following: 1, fire proof board It is the most commonly used materials in the market, which has the advantages of fire prevention, moisture, abrasion, oil, easiness to clean, and more varieties of colors. Installed in the building exit corridors, stairs and corridors, such as fire ceiling ceiling, it can ensure that people can be evacuated safely, and to protect people from the spread of the fire. 2, fire proof door, fire proof door is divided into wooden fire door, steel fire door and stainless steel fire door. Fire proof doors are usually used for the opening of the firewall, the entrance of the staircase, the evacuation of the aisle, the openings and other parts of the pipeline, the fire prevention, playing an important role in reducing the loss of fire. 3, fire shutter It can be set in the location where it is not convient to install a fire proof wall, fire shutter generally has functions such as good fire resistance, heat insulation, smoke, compression, anti aging, wear and corrosion. 4, fireproof and mothproof wood fire wood moth is made by putting ordinary wood into the solution containing calcium and aluminum, and then into the solution containing phosphate and silicate. In this way, two ion will be undergong chemical reaction in the wood, forming materials similar to the ceramic, and filling the gap of cells and tissues, so that allowing it to have fireproof and mothproof performance.

- Q: What are the models of refractory cables?

- There are bout four types. 1.NA-YJV / NB-YJV Crosslinked polyethylene insulated PVC sheath A (B) class fire-resistant power cable 2.NA-YJV22 / NB-YJV22 Crosslinked polyethylene insulated steel belt braiding PVC sheath A (B) class fire-resistant power cable 3.WDNA-YJY / WDNB-YJY Crosslinked polyethylene insulated polyolefin sheath A (B) class low smoke no halogen fire retardant power cable 4.WDNA-YJY23 / WDNB-YJY23 Crosslinked polyethylene insulated steel belt braiding polyolefin sheath A (B) class low smoke no halogen fire retardant power cable

- Q: What's the definition of fire endurance of the fire-resistant coating for steel structure?

- 1. Fire endurance. Conduct fire resistance test of any building component according to the standard time-temperature curve, and the time when it is subjected to the fire to the time when it loses support capability or fire insulation function or its integrality is destroyed is referred to fire endurance. 2. Steel has relatively low fire endurance which is usually 0.25h only, namely 15 minutes; 3. Of steel structure buildings, steel can be used as beams, pillars, etc. but its fire endurance is not enough (usually these components have higher requirement on fire endurance, and take pillar as an example, it is usually demanded that the fire endurance should be 2-3h), and under this condition, it needs to brush fire retardant coating so as to raise the fire endurance. As to the specific quantity or types of the fire retardant coating, it is decided upon the actual conditions. In short, the building material needs to meet the required fire endurance of the buildings.

- Q: What are the specific steps of stirring the steel ladle castable?

- Steps are as follows. 1 Compulsory mixer is used to stir the castable and bags, rope and other debris can not mix in the castable when stirred. 2, Castable should be unpacked on the scene. Stirred volume depends on the capacity of the mixer. Castable should be accurately measured and put into a blender. 3 The process of first dry mixing and then wet mixing is adopted. After the castable is added to the mixer, it is dryly mixed for 2 minutes, add about 5.2 to 5.5 percent of water and continue to add water while stirring. Water that is 80% of the total should be added, and then decide whether to continue to add or not depending on the consistence (noting that the water must be clean water and sewage can not be used). Then it is wetly mixed for 4 minutes and stirred for not less than 6 minutes at one time, until castable is even. In general, the bottom is slightly dry and the wall of the ladle is slightly dilute (the amount of water is only for reference). 4, The amount of water and mixing time should be controlled strictly when stirred to ensure that the needs of the consistency are met. If castable is too thin, it will seriously affect the quality of the material. The stirred volume, stirring time and water that is added should be consistent and they can not suddenly be thick or suddenly be thin. If the consistency does not meet the requirements, the castable should be put back to the mixer and stirred with appropriate water or dry materials. 5, It should be stirred evenly and casting should finish in 20 minutes, in order to avoid sclerosis, affecting structural strength of ladle lining 6, After each completion of construction, varieties of castable should be changed and the mixer should be cleaned 7, Stirring can stop in halfway. If the mixer breaks down and it can be repaired in a short time, some of the materials have to be removed before the machine is opened. If the machine can be repaired on time, castable refractory should all be removed.

- Q: Which one is the best refractory material?

- Resin bonded refractory is mainly abot aluminum magnesium carbon, and carbonaceous etc. Thermoplastic resins need to add the coagulant (Uto), ageing mixture for a period of time, so the production cycle is long. Hot hard resin is relatively not so complex, but it’s not as good as thermoplastic resins in thermoplastic binding.

- Q: How many refractories are there for boiler above 1200 ℃?

- In addition to refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and the like. Refractories often used are azs brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nitride, silicide, sulfide, boride, carbide and other nonoxide refractory materials, calcium oxide, chromium hemitrioxide, aluminium oxide, beryllia and other refractories. Thermal insulation refractory materials often used are diatomite product, asbestos product, insulation?board,etc. Unshaped refractories often used are repairing?mass, ramming?mass, castable refractory, plastic refractory, refractory mortar, refractory gunning mix, sling refractory, refractory coating, lightweight refractory?castables, stemming, etc.

- Q: what is the specs of thermal insulation refractory slab ?

- fireproof?panel is also called refractory slab, which refers to a layer of veneer. Its thickness is generally about 0.8 mm and there is a veneer made after compression of surface layer of paper, colored paper and multilayer kraft paper. Wear-resistant, heat-resistant and fire-resistant properties, scratch resistant and easy to clean, rich colors and good stability.

- Q: Pals who know something about fire resistant material please tell me how many types of refractory material there are

- Refractory materials used in special applications include high temperature oxcide, such as alumina, lanthanum oxide, beryllium oxide, calcium oxide, zirconia and other, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, mainly contain metal ceramic, high temperature inorganic coatings and fiber reinforced ceramics.

- Q: Which refractory is better for building 1500 degree kiln ?

- High alumina brick or 99 alumina hollow ball brick is OK, which can withstand a temperature of 1600 ℃.

- Q: What needs to be paid attention to in the construction of high- temperature refractory mortar?

- As far as I'm concerned, in the construction of high-temperature refractory mortar, these matters should be noted: 1. During the use of high-temperature daub masonry stove, the minimum mortar joint should be 0.5mm and general mortar joint should be 3-5mm, which can solve the processing and fine grinding of refractory brick on the brick grinder. Besides, it is conducive to the health of workers, and can reduce the masonry effort, ensure the quality and speed up the construction progress. 2. When making urgent repair on the stove, if the joint is much too large, 2-3mm refractory pieces can be appropriately added into the high- temperature refractory mortar, and stirred to fill the joint so as to shorten the repair time and ensure normal production. 3. High- temperature refractory mortar can be painted inside various furnace body, and it should be guaranteed that the surface of the furnace body has no dust or debris before painting.

Send your message to us

Raw Materials for High Density Oven Insulation Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords