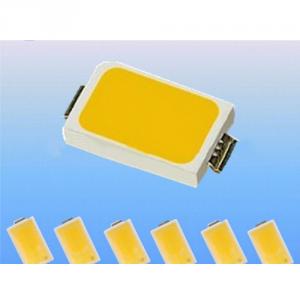

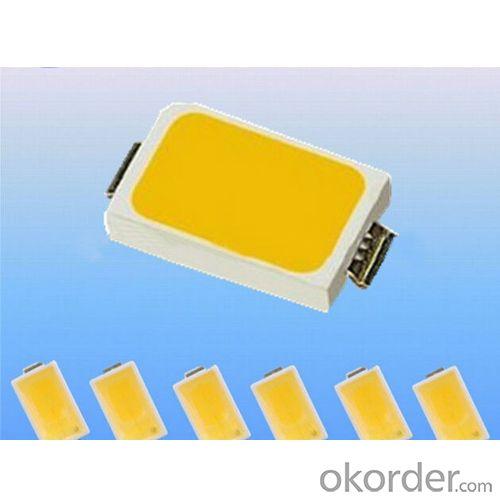

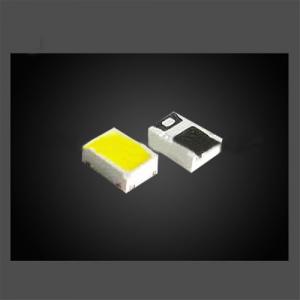

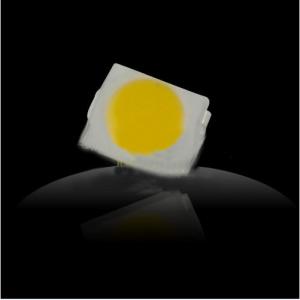

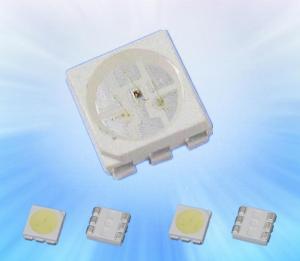

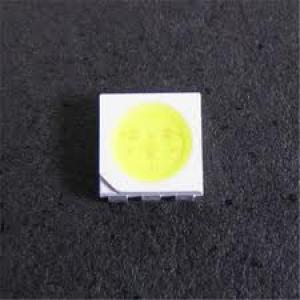

Shenzhen Factory High Brightness SMD5730 LED Chip

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 10000 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

Shenzhen Factory High Brightness SMD5730 LED Chip

Feature

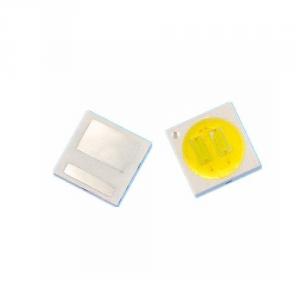

A)Size(mm):5.7*3.0*0.9

B)Emitting Angle:120 degree

C) Soldering Method: re-flow soldering

D)RoHS compliant

E)Dice Material: InGaN

F)Suitable for all SMT assembly and solder process.

Application

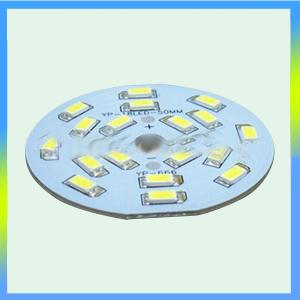

A) Optical indicator

B) Indoor lighting

C) Interior automotive lighting

D) Backing for LED,switch and symbol,display

E) Light pipe application

F) Advertisement

Specification

| Part No. | Dice | Lence Type | CRI | Luminous flux | Viewing Angle | |||

| Min. | Max. | Min | Max | 2θ 1/2 | ||||

| 5730W450-1B0 | White(InGaN) | Yellow Diffused | 70 | 87 | 40 | 45 | 120 | |

| 50 | 55 | |||||||

| 55 | 60 | |||||||

Electro-optical characteristics at Ta=25°C

| Parameter | Symbol | Min. | Type | Max. | Units | Test conditions |

| Forward Voltage | VF | 2.8 | 3.0 | 3.6 | V | IF=150mA |

| Reverse Current | IR | — — | — — | 10 | μA | VR=5V |

| Color Coordinates | X | — — | 0.371 | — — | — — | IF=150mA |

| Y | — — | 0.37 | — — | — — | IF=150mA | |

| Color Temperature | TC | 4000 | 4200 | 4500 | K | IF=60mA |

Electro-optical characteristics at Ta=25°C

| Power | Symbol | Rating | Units |

| Power Dissipation | Pd | 500 | mW |

| DC Forward Current | IF | 150 | mA |

| Peak Forward Current[1] | IFP | 200 | mA |

| Reverse Voltage | VR | 5 | V |

| Eletrostatic Discharge(HBM) | ESD | 1000 | V |

| Operating Temperature | Topr | —40-+85 | °C |

| Storage Temperature | Tstg | —40-+100 | °C |

Application notes

A) The LEDs should be kept at 30°C or less and 90@ RH or less. The LEDs should be used within a year. When storing the LEDs, moisture proof packing with absorbent material(sillica gel) is recommended.

B) The LEDs should be kept at 30°C or less and 70%RH or less. The LEDs should be soldred within 24 hours(1days) after opening the package. If unused LEDs remain, they should be stored in moisture proof packages, such as sealed containers with packages of moisture absorbent material(sillica gel). It is also recommennded to return the LEDs to the original moisture proof bag and to reseal the moisture proof bag again or it need to rebake before using next time.

Notes

Baking condition:temperature 70°C±5°C;humidity:less than 10%RH

Our Services

Reply your inquiry in 24 working hours

Customized design is available,OEM and ODM are welcomed

Delivery the goods to our customer all over the world with speed and precision

Offer customer the lowest price with high quality product.

- Q: What determines the brightness of the patch LED?

- The current through the lamp itself. If the same lamp, so it is necessary to ensure consistency in the different current circuit, the test voltage of little significance, especially in the case of parallel lamp, current a few beads each share is not the same, some big, some small.

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- (1): LED full color light emitting module display module is generally yellow green, pure green module price is more expensive; SMD full color LED display using pure green tube coreThe display module (2): LED full color pixel visual feeling is thick, low brightness, easy to have the mosaic phenomenon; patch LED full color consistent, high brightness;(3): maintenance module LED full color display is not easy to maintain, the whole module replacement cost is high; SMD full-color LED screen for easy maintenance, repair and replacement of single lamp;

- Q: How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- With double-sided adhesive, the temperature will not be very high. So it won't fall either. That's how I got it. It took me more than half a year, and I didn't have any problems

- Q: What is patch SMD-LED?

- This really do not know how to answer you, like a sheet of the same type of solder paste used to operate, it can be said that the plug-in is not, it is patch it!

- Q: What is the difference between patch LED beads and LED beads: General

- A pin of the lamp, and outside a resin cap, because the reason LED beads can spotlight cap;There is no pin on the patch and there is no resin cap outside. Because of the lack of cap, the LED patch can not be concentrated.LED patch lamp is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.

- Q: Patch LED beads can be bought in what place?

- If you don't want to constantly change with it, suggest you go to OSRAM, Nichia, Corey, Taiwan Tongjia enterprise authorized agency purchase.

- Q: How many volts is a single LED on the LED patch band?

- LED patch lamp is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.

- Q: What are the storage requirements of SMT patch LED (LED)?

- Clean? use no designated chemical liquids to clean SMD LED. These chemicals may damage SMD LED.. When necessary, wipe LED at room temperature with alcohol and dry at room temperature for 15 minutes before use? the effect of ultrasonic cleaning on SMD LED is related to the ultrasonic power and the SMD LED assembly method, and shall be checked in advance to ensure that the ultrasonic cleaning process does not impair the SMD LED

- Q: The quality of the LED patch module

- Luminous efficiency。 The LM value per watt is called luminous efficiency. This is an important criterion for judging whether LED is energy-saving or not. The incandescent lamp is about 14.4LM/W, the fluorescent lamp is about 51LM/W, the neon lamp is 43LM/W or so, and the LED is up to 150LM/W at present, but most of the LED light effects in our country are in 60~100LM/W. It should be noted that only the white light can achieve such high luminous efficiency in LED, and that red, yellow and blue are generally relatively low (mainly related to human visual definition). But compared with neon light, there is no heavy metal pollution, easy to maintain.

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- If the power of the lamp, because heat high power do very well, so not good welding, the temperature at the highest (300 degrees), the use of horseshoe iron head, not waiting to solder, because the heat is very powerful, quick action.

Send your message to us

Shenzhen Factory High Brightness SMD5730 LED Chip

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 10000 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords