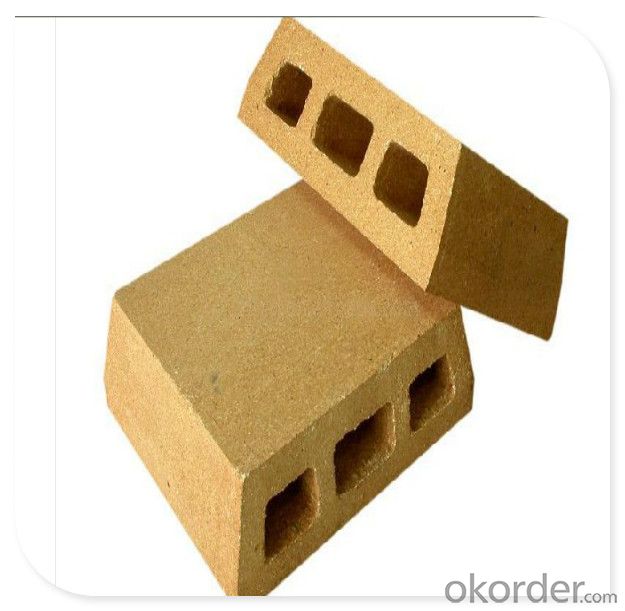

High Alumina Brick with Good Price - High Alumina Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina Refractory Brick with Good Price

Refractory brick Process:

Raw material to factory→ checkout→ burdening→stirring→mixing→taking out the raw material→transfer

→enter into mould→press machine extrusion→going out the mould→stoving→going into the furnace→firing

→stopping burn→cooling→open the furnace door→going out the furnace→checkout→packing→qualified product

→putting in storage→sale

| Item | Properties | |||||

| LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | ||

| Al2O3 (%) | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

| Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

| Bulk density (g/cm3) | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

| Softening temperature under load (°C ) | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

| Linear changes on reheating (%) | 1500°CX2H | 0.1 | 0.1 | 0.1 | 0.1 | |

| -0.4 | -0.4 | -0.4 | -0.4 | |||

| 1450°CX2H | 0.1 | |||||

| -0.4 | ||||||

| Apparent porosity (%) | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

| Cold crushing strength (Mpa) | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

| Application | steel furnace, glass furnace, sodium silicate furnace, ceramic shuttle kiln, cement rotary kiln, blast furnace, electric furnace, blast furnace and reverberatory furnace. | |||||

Our services:

1.Adhering to the business philosophy "Mutual Trust, Mutual Benefit, Mutual Profit, Faith Oriented".

2.According to your requirements to produce your order and OEM/ODM service is available.

3.Products are inspected through SGS and BV etc and accord with the international standard.

4.Your inquiry related to our products or prices will be replied in a timely manner.

Application:

Refracory brick plant can be in direct contact with the flame,this insulating brick can be used as linings or as thermal preservation layers in various industrial furnaces and kilns in metallurgical industry, ceramic industry, chemical industry, machinery industry.

such as blast furnace, hot blast stoves ,electric arc furnace, cement kiln,melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other thermal industrial equipment.

FAQ

1. Do you provide samples?

Yes, samples are free. Guarantee samples quality same as mass production quality.

2. What's the MOQ of trial order?

No limit,We can offer the best suggestions and solutions according to your condition.

3. Can we visit your company?

Of course,welcome at any time,seeing is believing.

4. Do you accept OEM?

Yes, we can do OEM.

5. What are the payment terms?

Usually T/T, D/A, D/P, L/C, Western Union ,others could be discussed .

6. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

7. How are your products’ quality?

More than 20 years of production experience. The products will be strictly inspected before shipment, so the quality could be guaranteed.

8. How to slove the quality problems?

If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

9. What is the service life of your bricks?

The service life of different bricks is unlike.It also depends on your using condition and method.

10. How about your company's certification?

ISO9001 and Test Report,also we could apply other necessary certification.

11. How about your price?

Quality will be guaranteed. Competitive prices based on same quality.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- According to my experience, two kinds of high alumina bricks from the index, there is a big difference between the content of AL2O3, a high aluminum brick in 75%, two grade high alumina bricks in 65%, so the content is not the same, also decided that the use of temperature difference, the difference is very big.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- Therefore, the choice and masonry of refractory bricks are of vital importance. If there is a brick kiln kiln off block process of reproduction, is now because of the use of refractory brick kiln material mostly three grade high alumina bricks. The content of AL2O3 is about 55%, of which the content of Fe2O3 is about 2%, which is weak, and the alkali corrosion resistance is a little worse. In a containing three grade high alumina bricks in the composition of AL2O3, Si2O3, and other elements also contain K, Na trace, were the most, thus causing the system of the low melting point is very low, even at 1400 DEG C has been liquid phase, and generate CaAL12O19 limestone and calcium feldspar etc.. Form corrosion loss. Therefore, a long time will cause the loss of block. On the one hand, it may be caused by construction.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3. High alumina brick refractory clay brick and brick than refractoriness to high. It belongs to high refractory. High alumina brick Al2O3 more, close to the neutral refractory material, can resist acid slag and alkaline slag erosion, because it contains SiO2, so the ability of alkaline slag resistance than acid resistant slag ability is weaker.According to the number of AL2O3 content is divided into, 55,65, 75,80 and so on several grades.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- Low creep and high alumina brick is based on the theory of "three stones". The combination of bauxite and clay as the main raw material, adding kyanite, andalusite and sillimanite, commonly known as the "three stone" control, physicochemical index and size composition, using alumina mullite corundum + + raw materials such as technical scheme. In the production process, first to detect and control indexes of raw materials, crushing, grinding, sieving process, according to the distribution ratio of ingredients, the size and moisture control of mud mixing after to meet the requirements of forming and molding machine, the use of qualified abrasives, blow molding control number, size and flash at the same time, the detection efficiency of semi-finished products and meet the requirements. Production process: high temperature calcination of high-grade alumina, adding small creep rate of high temperature materials, by high-pressure molding and high temperature firing. It has the characteristics of high strength, low creep rate and high use temperature. Widely used in high temperature furnace, hot air furnace hearth lining, brick and so on.

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Natural element minerals. Of minerals produced by an element (elementary substance). There are about 90 natural elements in the earth's crust, accounting for 0.1% of the total weight of the earth's crust. Can be divided into metal elements, mainly platinum and copper, silver, gold, etc., non-metallic elements, carbon, sulfur, etc., half metallic elements, arsenic, bismuth and so on.

- Q: Are there any differences between insulating bricks and refractory bricks?

- The refractoriness of insulating bricks is generally below 1400 tons, while the refractoriness of refractory bricks is above 1400 degrees. 3. density insulation bricks are generally lightweight insulation materials, the density is generally in 0.8-1.0g/cm3, and the density of refractory bricks are basically above 2.0g/cm3.

- Q: How are the grades of high alumina bricks differentiated?

- High alumina brick: aluminium silicate refractory product with a content of three Al2O3 (two) and more than 48%

- Q: The difference between clay bricks and clay bricks

- Sintering bricks do not have clay bricks, so sintering bricks are made of stone. Clay brick is clay cooking, two yo, qualitative difference, but the appearance and color almost, but the quality is very different, life expectancy is also a great gap.

Send your message to us

High Alumina Brick with Good Price - High Alumina Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords