High Alumina Brick - High Quality Refractory Products

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 8000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

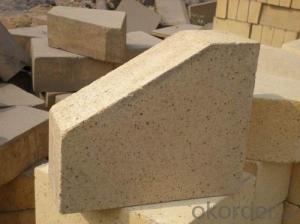

High Alumina Bricks Refractory Products of High Quality

Firebricks Description

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory,which has such advantages as high porosity, small volume density,good insulation effect,high mechanical intensity,small thermal conductivity and long service life.For various industrial kilns&furnaces,it is a kind of essential refractory for energy saving and temperature preservation.This series of High Alumina fire resistant brick are made of selected high alumina bauxite, kaolin caly,hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Firebricks Application

High alumina bricks are commonly used in blast furnace,hot blast furnace,the roof of electric furnace,teeming ladle,rotary kiln,regenerator etc.

Firebricks Features

.Low thermal conductivity

.Excellent acid and base slaging resistance

.High refractoriness

.Excellent thermal shock resistance

.Excellent mechanical strength

Firebricks Specification&Pictures

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 |

FAQ

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- According to my experience, two kinds of high alumina bricks from the index, there is a big difference between the content of AL2O3, a high aluminum brick in 75%, two grade high alumina bricks in 65%, so the content is not the same, also decided that the use of temperature difference, the difference is very big.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- Therefore, the choice and masonry of refractory bricks are of vital importance. If there is a brick kiln kiln off block process of reproduction, is now because of the use of refractory brick kiln material mostly three grade high alumina bricks. The content of AL2O3 is about 55%, of which the content of Fe2O3 is about 2%, which is weak, and the alkali corrosion resistance is a little worse. In a containing three grade high alumina bricks in the composition of AL2O3, Si2O3, and other elements also contain K, Na trace, were the most, thus causing the system of the low melting point is very low, even at 1400 DEG C has been liquid phase, and generate CaAL12O19 limestone and calcium feldspar etc.. Form corrosion loss. Therefore, a long time will cause the loss of block. On the one hand, it may be caused by construction.

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- From the year 2015 to the year 16 the end of the year, refractories industry presents two kinds of situations: one is a small business, a single product variety and equipment, to meet the demands of both environmental protection and the downstream market, such enterprises are generally in the Qing state inventory;

- Q: What are the main components of high alumina bricks?

- Sweat is like water mineral alumina bauxite, aluminum ore, magnesite, waves of gibbsite. Anhydrous alumina raw material, such as corundum, alumina, fused corundum. High alumina brick Zhengzhou gold company specializing in the production of various specifications, you can directly ask their technical staff.

- Q: How many cubic bricks does a high alumina brick have?

- It is related to the content of aluminum in high alumina bricks.

- Q: What's the price of high alumina refractory bricks?

- The price of high alumina refractory bricks varies greatly according to the content of AL2O3.

- Q: How to reduce porosity of high alumina brick

- High alumina brick used as refractory products in refractory material, has a great application in masonry kilns, insiders pointed out that the quality of high alumina brick general porosity and it has a great relationship! So, how to reduce the porosity of high alumina brick rate is very important!

- Q: Are there any differences between insulating bricks and refractory bricks?

- Heat preservation brick is to emphasize its heat preservation performance generally, not paying much attention to its refractoriness, but refractory brick is exactly the opposite. Different locations will use different materials, I hope we can choose carefully.

- Q: What is the apparent porosity of high alumina brick?

- Total porosity is porosity refers to the total volume of sample porosity in the percentage of total volume of samples. Apparent porosity refers to the percentage of the total volume of openings, pores, and total specimens in the sample.

- Q: High alumina brick 80 with which high aluminum cement?

- In order to maintain a reasonable comprehensive lining, should adopt high quality aluminum refractory mud, such as Sichuan resistance card phosphate refractory mud, refractory clay, high alumina refractory mud PA-80 LN-75, if you use the card volume of Sichuan resistant refractory clay masonry, the effect is better.

Send your message to us

High Alumina Brick - High Quality Refractory Products

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 8000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords