High Alumina Nitride Bonded Silicon Carbide Refractory Brick for Aluminum Electrolysis Cell Side Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

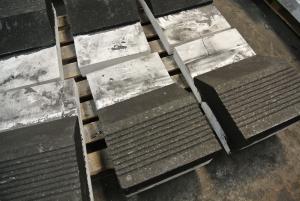

Nitride Bonded Silicon Carbide Refractory BrickThe product can be made at different sizes&Specifications on basis of your design. Widely used as a good lining materials in large or medium Aluminum reduction cells., steel kilns or ceramic furnace, etc.

It has good advantages of:

Low thermal conductivity

Low thermal expansion

Excellent oxidation resistance

Excellent corrosion resistance

Long duration

The Process: Mixing, Moulding, Drying, and Nitride Sintering at 1100-1500 celsius degree. Package: Normally, 1100kg or1200kg into a Non-fumigated crate, each piece is isolated by good padpaper, bubble film, or foam board, etc.

Note: All of our export package materials confirms to IPPC standard, with an official mark on them. Parameter: Item unit dataSiC % ≥ 72Si3N4 % ≥ 21Fe2O3 % ≤ 0.5Density g/cm3 2.65-2.70Apparent porosity % ≤ 18Modulus of Rupture Mpa(at ambient temperature) 42Mpa(1400 degree) 45Compressive strength MPA≥ 150Thermal conductivity1250degree W/m. K 15-18Acid-proof alkaline ExcellentSize Difference 0-100mm ± 1.0101-300mm ± 1.5301-500mm ± 2.0501mm above ± 0.5%Composite Sidewall Slab for Aluminum Reduction Cell (side wall block, combo brick)DescriptionWith special bonding developed by us, stick graphitic carbon pieces with SiC brick tightly. Can be used directly at Aluminum reduction cells. The feature: Excellent chemical&oxidation resistance, Longer duration, convenient for installation. And so on. Specification: 610mm*400mm*75/210mm, or other sizes as per your requirement.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- According to my experience, two kinds of high alumina bricks from the index, there is a big difference between the content of AL2O3, a high aluminum brick in 75%, two grade high alumina bricks in 65%, so the content is not the same, also decided that the use of temperature difference, the difference is very big.

- Q: What are the high aluminum bricks made of?

- It's OK to use corundum bricks and alumina hollow ball bricks to build a furnace,

- Q: Introduction of high alumina brick

- Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

- Q: Density of high alumina bricks

- High alumina brick by aluminum content is divided into four grades, three grade high alumina bricks content of not less than fifty-five percent, two grade high alumina bricks content of not less than 65, a high aluminum brick content of not less than 75, super high aluminium brick content above 85. As for the high aluminum brick shape, in addition to the standard high alumina brick, high alumina brick and general type, also called special high alumina brick, if the shape is very irregular it is usually called the specific type of high alumina brick, in short, to customized according to the specific use of kiln.

- Q: What materials are used for roof insulation?

- The other one is inorganic insulation materials, such as Portland, rare earth insulation, the thickness should be 5 cm or more, up to the high cost of auxiliary materials of construction, to reinforce, new inorganic insulation material, the material thickness, on the line of 2-3 cm, direct smear on the top of the house, without auxiliary material, than the price of wool, high aluminum silicate cotton.

- Q: How much is one ton / ton of high alumina refractory brick?

- The price of high alumina refractory bricks is not equal, according to the quality index of GB2988-2012

- Q: What are the requirements for refractory materials in heat treatment furnace?

- The structural strength of high temperature is evaluated by loading softening point. Load softening point is that under certain pressure (2 kg/ cm 2 = 0.2MPa) under the condition of heating rate to heating, measured the sample deformation (deformation for the original sample 0.6%) temperature. This temperature is called the softening point of the refractory. Sample size is Phi 36 x 50mm.

- Q: What's the weight of the refractory bricks?

- According to shape and size can be divided into standard brick, ordinary brick, special brick, etc.. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What causes breakage of refractory bricks?

- There are many factors that lead to the damage of refractory brick, can be divided into: the chemical loss (e.g. salt penetration, redox phenomenon), heat loss (burning, thermal shock), mechanical loss (kiln deformation, thrust, brick masonry quality etc.).

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- The gas will directly lead the dome combustion, in order to ensure good mixing, complete combustion of gas and air in a short time, the combustion capacity of short flame or flameless combustion burner, commonly used for semi jet short flame burner.

Send your message to us

High Alumina Nitride Bonded Silicon Carbide Refractory Brick for Aluminum Electrolysis Cell Side Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords