High Alumina Brick - Silicon Nitride Bonded Silicon Carbide Products for Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

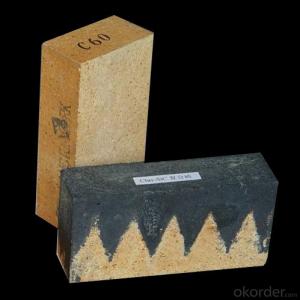

Use: blast furnace bosh, bosh, lower stack, cooling wall, garbage incineration furnace, boiler

Features: good thermal shock resistance, high bending strength, abrasion resistance, high alkali resistance and slag erosion ability, linear expansion rate low, high coefficient of heat conductivity.

Product name

Silicon nitride bonded silicon carbide products

Chemical

composition(%)

SiC

≥72.0

Si3N4

≥22.0

Fe2O3

≤0.3

Display the porosity(%)

≤16.0

The volume density(g/cm3)

≥2.68

Compressive strength at room temperature (Mpa)

≥180.0

Flexural strength

(Mpa)

Normal atmospherictemperature

≥45.0

1400℃

≥55.0

Thermal conductivity

λ(W/m·K)

The experimental temperature

650℃

19.5

The experimental temperature

1000℃

17.2

Coefficient of temperature conductivity

α(cm2/s)

The experimental temperature

650℃

0.064

The experimental temperature

1000℃

0.053

Linear expansion rate

α30—1000

4.02×10-6(k-1)

α30—1100

4.06×10-6(k-1)

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: What are the grades of high alumina bricks?

- According to the size of high aluminum brick is divided into: standard brick, special-shaped brick.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3. High alumina brick refractory clay brick and brick than refractoriness to high. It belongs to high refractory. High alumina brick Al2O3 more, close to the neutral refractory material, can resist acid slag and alkaline slag erosion, because it contains SiO2, so the ability of alkaline slag resistance than acid resistant slag ability is weaker.According to the number of AL2O3 content is divided into, 55,65, 75,80 and so on several grades.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- RT3 series trolley type resistance furnace is a national standard energy-saving cycle type operation furnace. It has super energy-saving structure, adopts fiber structure and saves electricity 30%. Exclusive production of composite high aluminum nails group, car anti-collision sealing brick, automatic sealing trolley and furnace door, integrated rail, without the basic installation, placed on the ground floor can be used. Mainly used for high chromium, high manganese steel castings, ductile iron, roller, steel ball, 45 steel, stainless steel quenching, annealing, aging, and various mechanical parts heat treatment. Features: 1, no noise, no environmental pollution. 2, small heat storage, less heat loss. 3, high temperature control accuracy, furnace temperature uniformity. 4, a high degree of automation, simple. 5, PID programming can be used to set, fully automatic operation. 6, good sealing, long life, safe and reliable. Widely used in chemical, petroleum, food, metallurgy, machinery, light industry, electricity, ships, paper, mining, medicine, central heating and other industrial sectors. With the development of social productive forces, its application in various industries is more and more widespread. Two, pitannealingfurnace (for example: flange heat treatment furnace) use: the furnace for metal parts, such as ring of equipment heat treatment at rated temperature: the furnace is composed of furnace body and a movable furnace cover and control system.

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- Hello Only on behalf of the Zhengzhou colt as refractory product index your answer to this question is not entirely separate from the chemical index of aluminum content, silicon content and judgment, personally think that three types of refractory bricks may respectively is: Two: semisilica brick high alumina brick

- Q: What are the specifications for bricks?

- Thecompressive node as a new type of building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, improve work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, it has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Prolong the sintering time and adjust the aluminum content of the high alumina brick.

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q: What is the difference between metal compounds and metal solid solutions?

- A series of intermetallic compounds occurring between transition metals in intermetallic compounds. The most important are L sigma sigma phase and ves phase, they are topologically close packed (TcP) phase, they consist of a small atomic radius of a dense layer, which is inlaid with a large atomic radius of atomic structure, this is a highly dense pile. In addition to atomic size factors, their formation is also influenced by the concentration of electrons.

Send your message to us

High Alumina Brick - Silicon Nitride Bonded Silicon Carbide Products for Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords