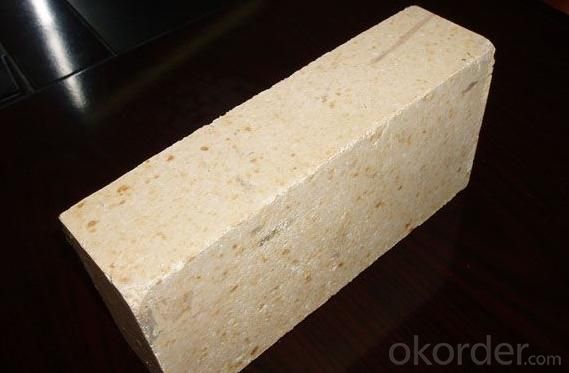

High Alumina Raw Materials for Refractory Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.High alumina material tubes made in China 2.O.E.M of 20 years experience

3.Application: casting iron

4.ISO&CE

5.Al2O3:63%

High alumina material tubes made in China

Raw material of High alumina material tubes made in China : High quality bauxite clinker

Main material of High alumina material tubes made in China : Mullite

Application of High alumina material tubes made in China : Special steel casting.

Production process of High alumina material tubes made in China :

The products are made of synthesized mullite and andalusite as raw materials, then shaped at high pressure and sintering at high temperature in furnace.

Characteristics:Good thermal shock resistance and chemical erosion resistance

Specifications for High alumina material tubes made in China :

Item | High alumina material tubes made in Chinafor special steel |

Al2O3 , % ≥ | 63 |

Apparent porosity % ≤ | 25 |

Bulk density g/cm3, ≥ | 2.3 |

Cold crushing strength MPa | 35 |

Refractoriness | 37 |

Reheating linear chang rate % 1550°C×2h | ±1 |

Thermal shock resistance(1100,water cooling )cycles | 5 |

- Q: what is best for making refractory insulation for Blast furnace, hot stove.

- High dimensional insulating blanket.

- Q: Is fireclay poisonous?

- Refractory materials are typically oxides, alumina, magnesium oxide and aluminate cement and etc, which are non-toxic.

- Q: What characteristics do A grade external wall fireproofing material have?

- 1. Save space and reduce costs; 2. Fireproofing, green and environmental protection; 3. Waterproofing; 4. Sound insulation; 5. Thermal insulation; 6. Install easily and shorten the construction period; 7. High safety performance.

- Q: What are included in roof thermal insulation fireproofing material?

- Aluminium foil, bubble, aluminium foil/air bubbles/fireproofing aluminium foil thermal insulation material, fireproofing bubble thermal insulation material, fire?retardant thermal insulation material, thermal insulation construction materials, aluminum foil insulation material.

- Q: What do we mean by saying that a ladle cover knots, elbow knots, blowpipe knots in refractory materials? What is the “knot”?

- Go eastward 200 meters from the south gate of cultural square.

- Q: What material is refractory material?

- alumina refractory concrete, silica brick clay brick, metal ceramic, high temperature machine coating fiber reinforced ceramics, diatomite product, asbestos products, insulation board refractory. The definition of refractory can be searched in the website.

- Q: What is required to do refractory material?

- Can you be more specific about what aspect?

- Q: Does refractory belong to metallurgical auxiliary materials?

- Refractory is widely used in industrial circle, such as metallurgy, chemical industry, petroleum, mechanical manufacturing, silicate and power, and its coonsumption is the maximum in metallurgy, accounting for 50% to 60% in total output. In order to improve slag-corrosion resistance of furnace lining, usually choose carbon-containing refractory. Refractory of various furnace lining are respectively: For the body, it is clay brick; as for the lower part, bosh and middle, it is SiC brick; for furnace bottom, it is carbon brick. Lattice brick is an important refractory product used in air heating furnace and regenerative chamber. Refractory is widely used in metallurgy. In order to improve slag-corrosion resistance of lining. Central line in tuyere and hearth are high-alumina brick. Refractory consumption is the maximum in metallurgy, accounting for 50% to 60% in total output. For the bosh and middle, it is SiC brick. In order to improve its thermal storage capacity: The furnace stack is clay brick. It is defined as refractory where the physical and chemical properties allows its use in high temperature environments; The lower furnace body

- Q: What are the requirements when producing fireproof materials by kaolin?

- . Kaolin are kaolinite crowded mineral composed of tiny flakes tubulose, lamellar smaller than 2 microns. it is composed of kaolinite, dickite, pearl stone, halloysite etc. I chemical formula of which is AL2O3-2SiO2-2H2O, the main mineral component is kaolinite and halloysite. Except kaolinite and halloysite there are other minerals montmorillonite, illite, pyrophyllite, quartz and feldspar associated. kaolin contains large amounts of the chemical composition AL2O3, SiO2, and a small amount of Fe2O3, TiO2, and small amounts of K2O, Na2O, CaO and MgO, etc. white pottery is made of kaolin and is now internationally accepted scientific name --Kaolin, derived from the eastern suburb of Jingdezhen high-Village side of the mountain kaolinite. kaolin plasticity, cohesiveness, certain dry strength, sinterability and whiteness after burning, making it the main raw material for ceramic production;. white, soft, highly dispersed, adsorption and chemical resistance with other excellent process performance, it has been widely used in the paper industry as well as industrial sectors such as agriculture and defense cutting-edge technology in the field of rubber, plastics, refractories, petroleum refining . according to the purpose and need, it can be processed, treated and purified, they can be used to produce activated clay.

- Q: What are the grades of refractory exterior wall thermal insulation materials?

- Classification of fire rating of extrior thermal insulation materials 1, According to national standard GB8624-97, the combustion performance of building materials are divided into the following grades A level: Incombustible building materials: Materials hardly burn. B1 class: Flame-retardant building materials: Flame-retardant material has good flame resistance. In case of fire in the air or at high temperature, it is difficult to catch fire and the fire will not spread quickly. And when the combustion source is removed, the burning will stop immediately. B2 Class: Combustible building materials: Combustible materials have a certain flame retardancy. In case of fire in the air or at high temperature, it will immediately burst into flames and it is easily to spread fire, such as wooden column, wooden roof truss, wooden beams and wooden stairs, etc. B3 level: Inflammable building materials: It has no flame retardant effect, and it is extremely inflammable, and the risk of fire is high. Classification of exterior wall thermal insulation materials according to fire rating: 1. Thermal insulation materials with A-level combustion performance Rock wool, glass wool, foam glass, foamed ceramic, foam cement, hole-closed perlite, etc. 2, Thermal insulation materials with B1-level combustion performance: Extruded polystyrene board (XPS) after special treatment / polyurethane (PU) after special treatment, phenolic aldehyde, gelatine powder polystyrene granule, and etc. 3. Thermal insulation materials with B2-level combustion performance: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

Send your message to us

High Alumina Raw Materials for Refractory Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords