High Alumina Brick - Refractory Firebrick SK36 Supplied by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 40%~43% | Al2O3 Content (%): | 55%~58% | MgO Content (%): | 0.8-1.2 |

| CaO Content (%): | 0.01 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.1~0.3% |

| SiC Content (%): | 0.00% | Model Number: | SK36 | Brand Name: | cnbm |

| Firebrick SK36 Bulk density(g/cm3):: | ≥2.25 | Firebrick SK36 Refractoriness(°C): | ≥1790 | Cold cushing strength (mpa): | ≥46MPa |

| SK36 Firebrick Porosity(%): | <23 | efractoriness under load 0.2mpa(°C): | >1450 | SK36 Firebrick Na2O+K2O(%): | <2.3 |

| Firebrick Thermal expansion at 1000°C(%): | ≤0.3 | Reheating shrinkingchange(%) 1500°CX24h: | -0.3 | Refractory SK36 Model Number: | DDSK36 |

| Refractory SK36 Brand Name: | DD |

Packaging & Delivery

| Packaging Details: | wooden pallet |

| Delivery Detail: | Shipped in 15 days after payment |

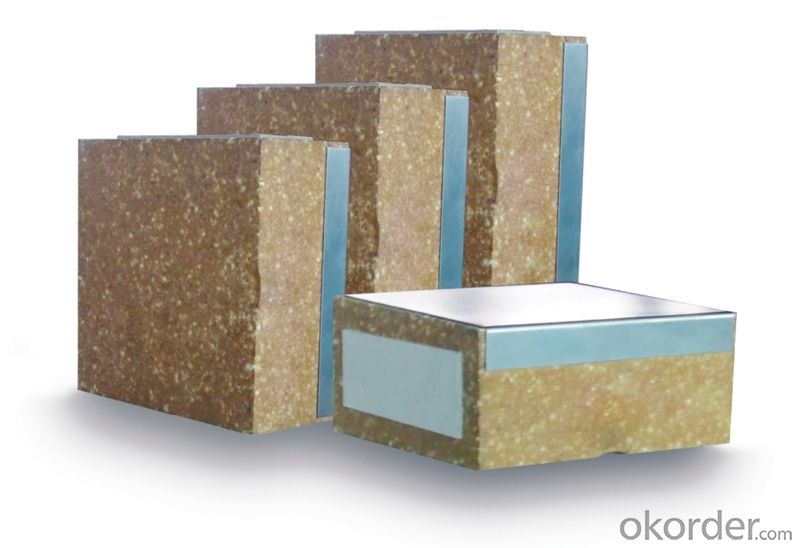

Factory supply refractory firebrick SK36

Category of Refractory Brick/Fire Brick:

a) According the made method, it can be divided into burnt brick, unburned brick, and electric smelting brick.

b) According the shape and size, it can be divided into standard brick, general brick and abnormal shape brick.

c) According the content of the Al2O3, it can be divided into fire clay brick and high alumina firebrick.

Firebrick SK36 Index

Item | SK38 | SK37 | SK36 | SK34 |

Al2O3 % | ≥75 | ≥65 | ≥55 | ≥48 |

Cold crushing strength ,MPa | ≥54 | ≥49 | ≥44 | ≥40 |

Apparent porosity ,% | ≤23 | ≤23 | ≤22 | ≤22 |

Refractoriness under load , °C | ≥1520 | ≥1500 | ≥1470 | ≥1420 |

Reheating linear change (1500°C,2h) % | +0.1-0.4 | +0.1-0.4 | +0.1-0.4 | (1450°C,2h)+0.1-0.4 |

Refractoriness °C | >1790 | >1790 | >1770 | >1750 |

- Q: What is the difference between corundum and high alumina??

- The main component of high purity 99 corundum brick is corundum sand,90 corundum brick is mainly composed of corundum sand and a small amount of Suzhou soil, mullite.

- Q: What is the price of the latest thermal insulation material?

- Also through online pre understand the products and prices, and now have large-scale manufacturers are generally opened on the cable business. Goods than three, manufacturers on-site inspection, confirm the quality of goods after considering cooperation.

- Q: Application characteristics of high alumina brick

- Thermal shock stability. In high alumina brick products, the stress concentration is due to differential expansion when the temperature of refractory brick changes. Therefore, the high aluminum brick products than clay brick products thermal shock stability is poor, general water temperature only 3 - 5 times.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- The brick Pei boring and time. 6, Pei brick kiln installed between the brick and the brick Pei order, Pei and kiln top, kiln wall gap etc.. 7, high alumina brick kiln plan, and the lack of edges and corners of the scene should be avoided.

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Natural element minerals. Of minerals produced by an element (elementary substance). There are about 90 natural elements in the earth's crust, accounting for 0.1% of the total weight of the earth's crust. Can be divided into metal elements, mainly platinum and copper, silver, gold, etc., non-metallic elements, carbon, sulfur, etc., half metallic elements, arsenic, bismuth and so on.

- Q: The difference between light high alumina brick and heavy aluminum brick

- Lightweight high alumina brick, also called high alumina insulation brick. Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. Volume density 0.4 - 1.35g/cm3. Porosity 66% - 73%, compressive strength 1 - 8MPa. Better thermal shock resistance. Usually, a high alumina clinker is added with a small amount of clay. After grinding, it is poured and shaped in the form of slurry by gas generation or foam method, and it is fired at 1300 - 1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: What's the weight of the refractory bricks?

- According to shape and size can be divided into standard brick, ordinary brick, special brick, etc.. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- Refractory bricks are stone powder and clay paste. They are fired in a kiln of 1300 degrees. The upper limit is 1500 degrees above normal pressureRefractory bricks - refractory materials of a specified shape and size.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The rotary kiln lining structure of rotary kiln and requirements on refractories calcining active lime according to the general output is divided into Nissan 300t, 400 t, 600 t, 800 t, 1000 t, 12000 t of kiln type, calcining zone temperature at 1350 degrees celsius. The kiln is divided into a discharge end, a cooling zone, a burning zone, a preheating zone and a feeding end, and the temperature of each section of the kiln ranges from 1000 DEG C to 1350 DEG C, and the requirements for refractory materials are different. The kiln refractory materials not only to withstand the high temperature impact, but also need to bear the material erosion, kiln rotation stress produced, so not only on the physico-chemical properties of refractory materials have strict requirements, but also for the construction of brick should be strictly.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- Top burning type hot blast stoveIt means that the burner is installed on the top of the hot blast furnace of the iron making equipment, and it does not need a special combustion chamber in the vault space. It is also called a non combustion chamber type hot blast stove.

Send your message to us

High Alumina Brick - Refractory Firebrick SK36 Supplied by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords