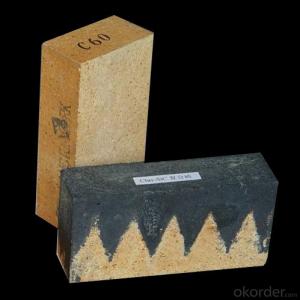

High Alumina Brick - HiTech 1760C 42% Al2O3 Refractory Firebrick for Kilns

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | ≤53 | Al2O3 Content (%): | >42% | MgO Content (%): | none |

| CaO Content (%): | none | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | none |

| SiC Content (%): | none | Model Number: | JN | Brand Name: | CNBM |

| Fe2O3: | ≤2.4% | Refractoriness ℃: | 1760 | Bulk density g/cm3: | ≥2.1 |

| Apparent porosity %: | ≤23 | Cold crushing strength MPa: | ≥30 | Refractoriness under load ℃: | ≥1380 |

Packaging & Delivery

| Packaging Details: | in wooden pallets |

| Delivery Detail: | 25 days |

Features

1. Low bulk density, low thermal conductivity, good thermal insulation performance.

2. Refractory category allow direct contact of fire, suitable ofr various atmosphere

3. Good integrity with furnace lining, long service life, easy operation, could be shaped freely

Typical Applications

1. Furnaces of metallurgy industry, heat treatment furnace

2. Furnaces of chemical industry and construction industry.

3. Furnace of incineration of garbage, recirculating fluidized bed furnace etc.

Specification:

Refractory fireclay brick

Item Specifications | N-1 | JN-40 | JN-42 | |

Al2O3 % | ≥42 | ≥40 | ≥42 | |

Fe2O3 % | ≤2.3 | ≤2.7 | ≤2.5 | |

Refractoriness ℃ | 1760 | 1760 | 1760 | |

Apparent porosity % | ≤22 | ≤24 | ≤23 | |

Bulk Density≥ g/cm3 | 2.25 | 2.20 | 2.25 | |

Refractoriness under load 0.2MPa℃ | 1400 | 1380 | 1450 | |

Cold crushing strength MPa | 35 | 28 | 35 | |

Permanent linear chang % | 1500℃×2h | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 |

- Q: What is the heat preservation material used in a laboratory furnace?

- Asbestos, high alumina brick, or carbonized silicon are often used.Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

- Q: Introduction of high alumina brick

- Three alumina silicate refractory product with a content of two Al2O3 (48%).

- Q: How much is one ton of high alumina refractory brick?

- Three high aluminum refractory brick Zhengzhou Kuwait is generally around 800. 32 years of experience, good.

- Q: What are the requirements for Rubble backfill height?

- 1, filling thickness is not greater than 50cm.2, filling, the use of layered filling.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: How are the high alumina bricks fired?

- Generally, the high alumina bauxite is added with a small amount of clay. After being ground, the gas is injected and shaped in the form of slurry by the way of gas attack or foam, and it is burnt at 1300~1500 DEG C. Sometimes industrial alumina can be used to replace part of bauxite clinker. Used for lining and thermal insulation of masonry kilns, as well as for areas where there is no high temperature, high melting material erosion and erosion effects. When touching the flame directly, the touch temperature shall not be higher than 1350 degrees.

- Q: What materials are used for roof insulation?

- The other one is inorganic insulation materials, such as Portland, rare earth insulation, the thickness should be 5 cm or more, up to the high cost of auxiliary materials of construction, to reinforce, new inorganic insulation material, the material thickness, on the line of 2-3 cm, direct smear on the top of the house, without auxiliary material, than the price of wool, high aluminum silicate cotton.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q: What is the difference between high alumina brick and clay brick?

- Lightweight high alumina bricks are usually made of high alumina bauxite clinker with a small amount of clay. After grinding, the bricks are poured and shaped in the form of slurry by gas or foam method. They are fired at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: High alumina brick 80 with which high aluminum cement?

- In order to maintain a reasonable comprehensive lining, should adopt high quality aluminum refractory mud, such as Sichuan resistance card phosphate refractory mud, refractory clay, high alumina refractory mud PA-80 LN-75, if you use the card volume of Sichuan resistant refractory clay masonry, the effect is better.

Send your message to us

High Alumina Brick - HiTech 1760C 42% Al2O3 Refractory Firebrick for Kilns

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords