High Alumina Brick - Grey High Refractoriness Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory Brick Grey High Refractoriness

Brief discription for Refractory Brick Grey

CMAX high alumina refractory bricks are classified according to alumina content ranging from 48% to 90%.

CMAX Refractory Brick Grey are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for Refractory Brick Grey

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for Refractory Brick Grey

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

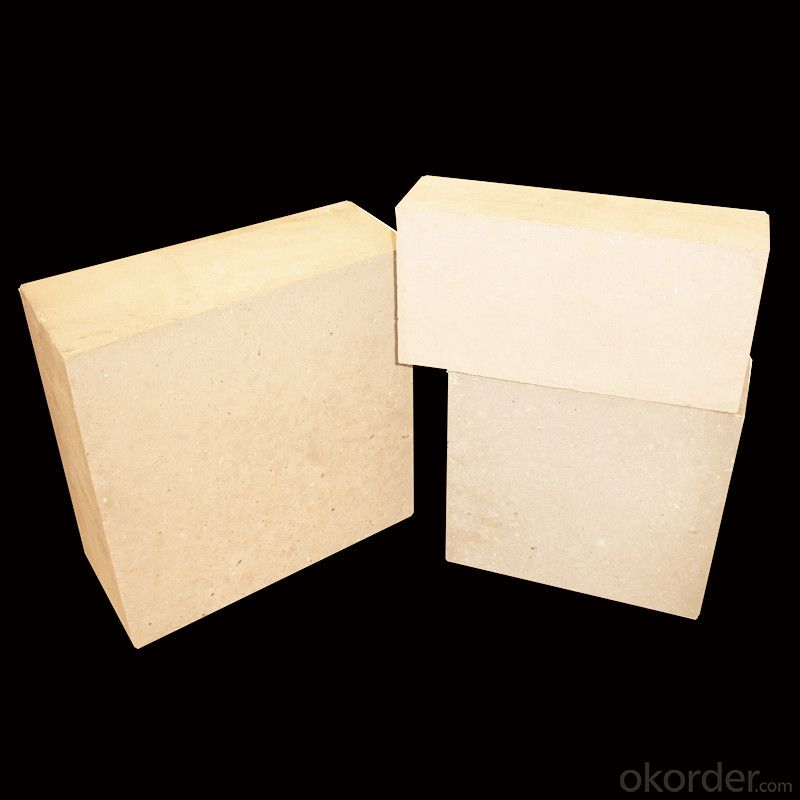

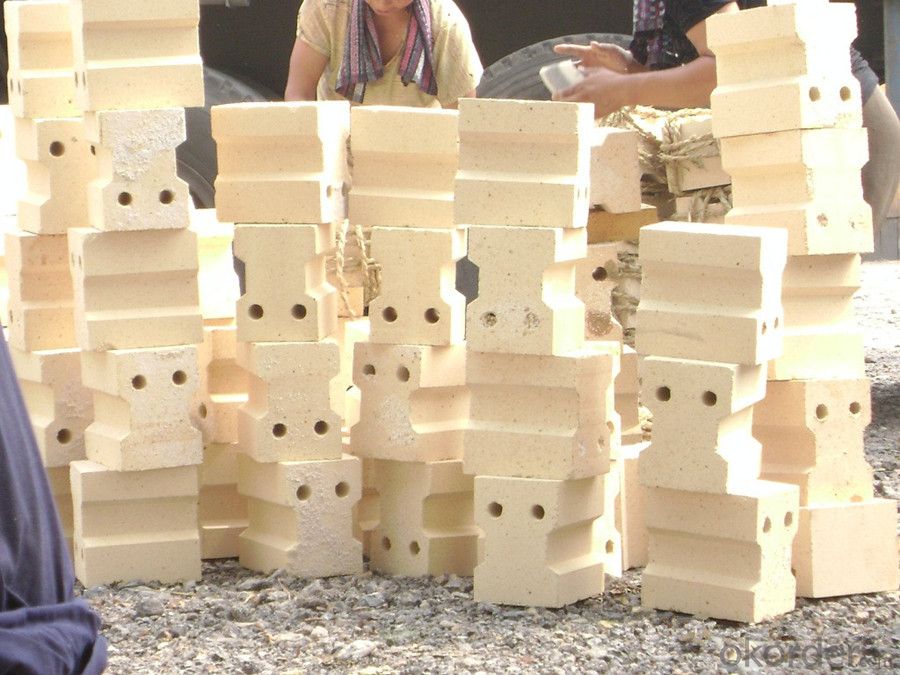

Images/photographs for Refractory Brick Grey

◆ breif images-different shape for different usage

◆ Packaging for Refractory Brick Grey

◆ Producing Equipment for Refractory Brick Grey

◆ Testing Mashines for high alumina bricks

WHO WE ARE?

CNBM International (China National Building Materials Group Corporation) 500 Fortune Company.

we are the main supplier for

ALLIED MINERAL PRODUCTS, INC

REFRACTORIES INCORPORATED

SRS SORG REFRACTORY SYSTEMS GMBH,

SUNWARD REFRACTORIES CO., LTD

LILAMA69-1 JOINT STOCK COMPANY etc.

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: What is fireproof concrete?

- A series of concrete with fire resistance and heat resistance is made of Portland cement series as cementing material and heat-resistant material as aggregate. Silicate fireproof heat-resistant concrete with Portland slag cement, Portland cement and water glass as cementing material, broken clay brick, clay, cement clinker, broken high alumina brick as aggregate.

- Q: What is the heat preservation material used in a laboratory furnace?

- Thermal insulation cotton is a high-purity clay clinker, alumina powder, silica powder, chromium sand and other raw materials in the industrial furnace melting at high temperature, forming fluid. Then, compressed air is used to blow or use the wire throwing machine to turn the yarn into a fiber shape. After the cotton collector is collected, the cotton is formed into a heat preservation cotton.The high alumina brick is usually made of high alumina clinker with small amount of clay. After grinding, the high alumina brick is poured and shaped in the form of slurry by the way of gas generation or foam, and it is burnt at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: What refractory material does cupola lining use?

- It's made of high quality refractory material: 1770 ~ 2000 centigrade.

- Q: What is the standard size of high alumina brick?

- The country has laid down a number of criteria for the use of refractory bricks to unify market demand.

- Q: How many cubic bricks does a high alumina brick have?

- It is related to the content of aluminum in high alumina bricks.

- Q: How to reduce porosity of high alumina brick

- When proportioning, the ratio of coarse to medium to fine is 4:2:4, and the maximum particle size should be no more than 5mm. The mixing order is as follows: first adding coarse particles, then adding sulfite pulp waste liquid, premixed 3min, then adding high aluminum fine powder for mixing. The operation process is coarse and fine particles added in sulfuric acid with crushed pulp waste.In order to reduce the porosity, our company suggested that the single-sided pressure changed to double-sided pressure instead of double-sided pressure, the number of strikes should also vary according to the amount of feeding. If the kiln is fired, the location of the fire hole shall be adjusted so that the middle part is dense, the edge is thin, and the door near the kiln is properly encrypted so that the temperature difference between the furnace top and bottom and the temperature difference between the inside and outside are not greater than 20 degrees.

- Q: Corundum, high alumina and fireclay refractory difference is what

- In fact, they are not consistent with raw materials, corundum refractories can use white corundum, white corundum, brown corundum corundum material, alumina content of these materials is higher than 90%, while the high aluminum refractory material is bauxite, alumina in 90 to less than 70, and clay raw materials the aluminum content is less than 70..

- Q: What is the difference between high alumina brick and clay brick?

- Light clay brick, refractory material is a kind of high porosity, low density, low thermal conductivity of refractory material, refractory materials called lightweight refractories, it includes insulating refractory products, refractory fiber and refractory fiber products. Heat insulation refractory material is characterized by high porosity, general 40%-85%, low volume density, lower than 1.5g/cm3, low thermal conductivity, generally lower than 1.0W (m.K). The utility model has the function of heat insulation of an industrial furnace, and can reduce the heat dissipation loss of the kiln, save energy, and can reduce the quality of the thermal engineering equipment. The mechanical strength, wear resistance and slag resistance of insulating refractory material are poor, and it is not suitable for the load-bearing structure of kiln and direct contact with slag, burden, molten metal and other parts.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- The gas will directly lead the dome combustion, in order to ensure good mixing, complete combustion of gas and air in a short time, the combustion capacity of short flame or flameless combustion burner, commonly used for semi jet short flame burner.

Send your message to us

High Alumina Brick - Grey High Refractoriness Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords