High Alumina Brick - Curved Dense Line Fire Resistant for Blast Furnaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina Refractory Bricks For Blast Furnaces

High alumina bricks of over SK35 contain over 45% Alumina and are made from raw materials of unusually high degree of purity of Bauxite and refractory clay. For serve under severe conditions,JUCOS Alumina bricks have excellent mechanical strength, good resistance to thermal spalling, and are highly resistant to chemical attack by vilatile alkaies and some slag. We manufacture and design alumina bricks to meet the requirements of a great variety of service conditions thorough quality control.

Standard size: 230 x 114 x 65 mm ,Special size and OEM Service also provided. The size is precise, providing kinds of shapes according to customer's drawing

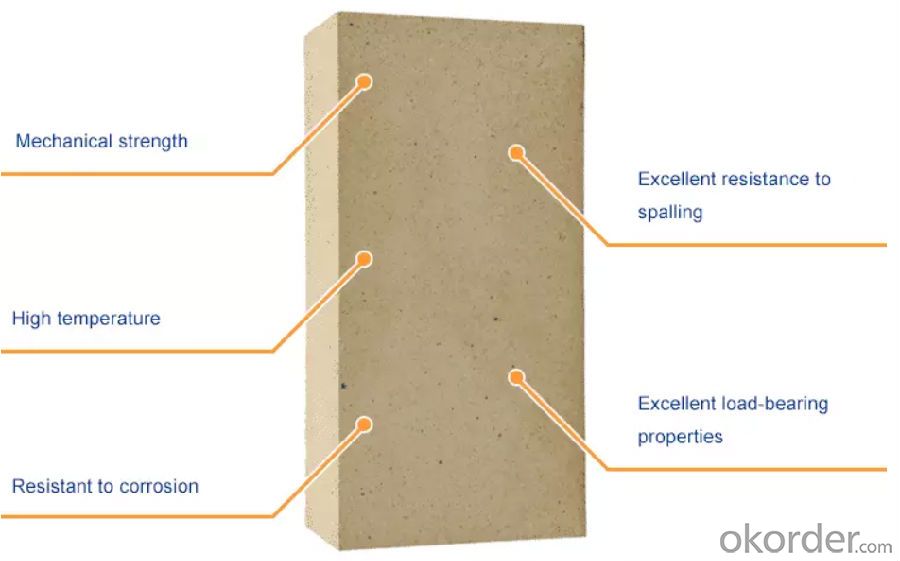

Features Of High Alumina Brick

Mechanical strength

High temperature

Excellent resistance to spalling

Resistant to corrosion

Excellent load-bearing properties

Applications Of High Alumina Brick

Nonferrous Metal Furnace

Rotary & Shaft Kiln

Various Incinerator

Reheating Furnace

Permanent Lining For EAF Ladle

General Industrial Furnace etc.

Specifications Of High Alumina Brick

High-alumina refractory birck

JUCOS Alumina contents range from 48% to 85%

Widely used throughout metallurgical industry

Physical And Chemical Indicators For High Alumina Brick

Brand Properties | SK-40 | SK-38 | SK-37 | SK-36 | SK-35 | |

Refractoriness (SK) | 40 | 38 | 37 | 36 | 35 | |

Apparent Porosity (%) | 22 | 23 | 23 | 23 | 23 | |

Bulk Density (g/cm3) | 2.65 | 2.40 | 2.35 | 2.30 | 2.25 | |

Cold Crushing Strength(MPa) | 70 | 52 | 50 | 45 | 40 | |

Thermal Linear Expansion(%) @1000deg | 0.6 | 0.6 | 0.6 | 0.6 | ||

Permanent Linear Change(%) @1400degx2hrs | ±0.2 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | |

Refractoriness under Load (℃) @0.2MPa | 1,530 | 1,500 | 1,450 | 1,420 | 1,380 | |

Chemical Composition(%) | Al2O3 | 80 | 72 | 60 | 50 | 45 |

Fe2O3 | 1.8 | 2.0 | 2.0 | 2.0 | 2.0 | |

Pictures Of High Alumina Products

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- According to my experience, two kinds of high alumina bricks from the index, there is a big difference between the content of AL2O3, a high aluminum brick in 75%, two grade high alumina bricks in 65%, so the content is not the same, also decided that the use of temperature difference, the difference is very big.

- Q: What is the difference between corundum and high alumina??

- The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: What are the grades of high alumina bricks?

- According to the size of high aluminum brick is divided into: standard brick, special-shaped brick.

- Q: The difference between aluminium refractory and magnesia refractory

- Aluminum refractory belongs to neutral refractory material, usually refers to silicon aluminum refractory materials, such as: high alumina brick, clay brick, high alumina castable and other products, the production of raw materials is mainly bauxite.

- Q: How are the high alumina bricks fired?

- Light and high alumina bricks are usually fired in a weak oxidizing atmosphere. In light and high alumina bricks firing, they are often rich in impurities such as R2O, RO, Fe2O3 and so on. They react with Al2O3 and SiO2 at high temperature to produce liquid phase. In the Al2O3 - SiO2 - R2O system, the growth rate of liquid phase increases with the increase of temperature at high temperature. So, because the increase of sintering temperature brings a lot of liquid phase, the decrease of liquid viscosity will lead to the deformation of brick and the decline of brick high temperature function. Therefore, the lower sintering temperature and longer holding time should be adopted in the sintering process dominated by liquid phase sintering. The production practice shows that the same firing temperature can be used for the high grade aluminum bricks. When fired in an inverted flame kiln, it is usually 1430 degrees centigrade and insulated by 40H. The high alumina bricks such as Ill are 1390~1420 degrees centigrade. When the tunnel kiln is fired, they are 1550 and 1450~1500 degrees centigrade respectively. High alumina brick is usually made of weak oxidizing atmosphere.

- Q: What are the specifications for bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: The difference between light high alumina brick and heavy aluminum brick

- Lightweight high alumina brick, also called high alumina insulation brick. Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. Volume density 0.4 - 1.35g/cm3. Porosity 66% - 73%, compressive strength 1 - 8MPa. Better thermal shock resistance. Usually, a high alumina clinker is added with a small amount of clay. After grinding, it is poured and shaped in the form of slurry by gas generation or foam method, and it is fired at 1300 - 1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Before making bricks, the raw materials are usually tested and tested to see if the aluminum content is up to standard

- Q: What's the weight of the refractory bricks?

- Fireclay refractory bricks: 3.4kg-3.8kg - according to the quality of raw materials, prices ranging from 1 yuan to 2.7 yuan, high alumina refractory brick: three, high aluminum in 3.9kg or so. Ordinary T-3 firebrick weight calculation method: 230*114*65*2.2/2.1.

- Q: What causes breakage of refractory bricks?

- Refractory brick is a non metal mineral products can be used in the high temperature of 1550 DEG C under belongs to a class of inorganic, used in high-temperature furnace lining materials as protection kiln, which causes damage, usually have these points.Furnace temperature is not clear, there is no corresponding choice of refractory bricks.Physical impact, abrasion and erosion cause damageChemical factors, especially chemical industry, should be made of refractory bricks, which should be resistant to penetration and erosionIV: products from the factory when the factory did not pass the quality inspection standards

Send your message to us

High Alumina Brick - Curved Dense Line Fire Resistant for Blast Furnaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches