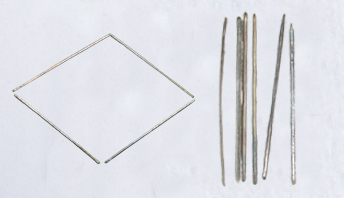

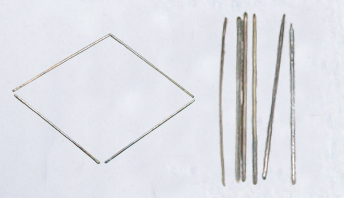

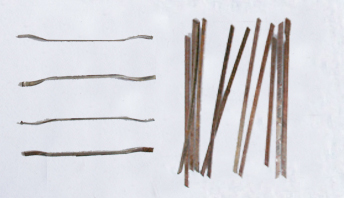

Heat-resistant stainless steel fibers melt pumping

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Fiber Grade:

The grades of steel fiber should be suitably selected based on the temperature and atmosphere.

Physical, Mechanical and corrosion resistant properties of stainless steel fiber

| 304 | 310 | 330 | 446 | 430 |

Melting Point Range ℃ | 1400-1425 | 1400-1450 | 1400-1425 | 1425-1510 | 1425-1510 |

Elastic modulus at 870℃ | 12.66 | 12.66 | 13.71 | 9.84 | 8.44 |

Tensile strength at 870℃ | 127 | 155 | 197 | 54 | 48 |

Thermal expansion coefficient at | 20.16 | 18.58 | 17.64 | 13.14 | 13.68 |

Heat conductance at 500℃ | 21.5 | 18.7 | 21.6 | 24.4 | 26.3 |

Specific gravity at romm temperature, g/cm³ | 8.0 | 8.0 | 8.0 | 7.5 | 7.8 |

Loss of weight (%) after 1000 hours of circulating oxidization at 982℃(%) | 70(100h) | 13 | 18 | 4 | 70(100h) |

*Violent circulating state in air | 870 | 1035 | 1035 | 1175 | 870 |

982 | 1050 | 1150 | 1095 | 815 | |

Corrosion in H2S,Mil/yr | 200 | 100 | / | 100 | 200 |

Recommended max operating temperature when it is used in SO2℃ | 800 | 1050 | / | 1025 | 800 |

Corrosion in natural gas at 815℃ |

| 3 |

| 4 | 12 |

Corrosion in coking coal gas at 982℃ | 225 | 25 | 75 | 14 | 236 |

Nitrogenization in anhydrous ammonia at 525℃ | 80 | 55 | 20 | 175 | <304# |

Corrosion by CH2 at 454℃, Mil/yr | 4.8 | 2.3 |

| 8.7 | 21.9 |

Carbon pick-up of alloy % with solids carbonized at 982℃ for 24 hours and 40 times of circulations, % | 1.40 | 0.02 | 0.08 | 0.07 | 1.03 |

- Q: Can stainless steel wire be used for automotive springs?

- Yes, stainless steel wire can be used for automotive springs. Stainless steel has excellent corrosion resistance and high tensile strength, making it a suitable material for springs that are exposed to harsh environments or require high durability.

- Q: Can stainless steel wire be used for wire ropes in elevators?

- Yes, stainless steel wire can be used for wire ropes in elevators. Stainless steel wire ropes are commonly used in elevators due to their high strength, corrosion resistance, and durability.

- Q: Can stainless steel wire be used for wire rope thimbles?

- Yes, stainless steel wire can be used for wire rope thimbles. Stainless steel is a commonly used material for wire rope thimbles due to its corrosion resistance and durability.

- Q: Can stainless steel wire be used for architectural applications?

- Yes, stainless steel wire can be used for architectural applications. It is a versatile material known for its strength, durability, and resistance to corrosion, making it suitable for various architectural purposes such as balustrades, handrails, mesh screens, and decorative elements.

- Q: Can stainless steel wire be used for hanging artwork or decorations?

- Yes, stainless steel wire can be used for hanging artwork or decorations. Stainless steel is a strong and durable material that can support the weight of various artworks or decorations, making it a suitable choice for hanging purposes.

- Q: Can stainless steel wire be used for hanging signs or banners?

- Certainly! Hanging signs or banners can utilize stainless steel wire effectively. The strength and durability of stainless steel wire make it a fitting selection for supporting weighty objects like signs or banners. Furthermore, stainless steel wire's resistance to corrosion guarantees its endurance and prevents rusting and deterioration. Its flexibility also enables effortless installation and adjustment. In summary, stainless steel wire proves to be a dependable and enduring choice for suspending signs or banners.

- Q: 201 stainless steel hydrogen withdrawal what are the uses?

- Most of the 200 series stainless steel produces almost lower levels of austenitic stainless steel by replacing part or all of the nickel with manganese (and nitrogen) in accordance with the national standard for controlling sulfur and carbon content. This series of materials is 18% chromium content and low nickel content is not up to the balance and the formation of ferrite, the chromium content of 200 series stainless steel in down to 15% to 16%, some cases dropped to 13% ~ 14%, its corrosion resistance is also not with 304 and other similar compared with steel, common corrosion in acidic conditions and the deposition area gap, manganese and copper in some cases reduced repassivation effect. The damage rate of the 200 series steel under these conditions is about 10-100 times of that of 304 stainless steel. Also, in production, it is often impossible to control the residual sulfur content and carbon content of these steels. The material cannot be traced back, even in the case of material recycling. If they do not show Cr-Mn steel, they will become a dangerous mixture of scrap steel, resulting in castings containing unexpected high manganese content.

- Q: Can stainless steel wire be used in marine environments?

- Indeed, stainless steel wire proves to be suitable for deployment in marine environments. Its exceptional resistance to corrosion and rust renders it an optimal selection for deployments in marine environments, where the wire will be subjected to saltwater, high humidity, and other demanding circumstances. The presence of chromium in stainless steel generates a safeguarding layer on its surface, effectively impeding corrosion and guaranteeing the wire's sturdiness and endurance. Furthermore, stainless steel wire possesses outstanding strength and flexibility, rendering it appropriate for a multitude of marine applications, including rigging, fishing, boat construction, and marine engineering projects.

- Q: Can stainless steel wire be used for hanging lights?

- Yes, stainless steel wire can be used for hanging lights. Stainless steel wire is strong, durable, and resistant to corrosion, making it a suitable choice for hanging lights both indoors and outdoors.

- Q: Is stainless steel wire suitable for wire rope hooks?

- Wire rope hooks can be suitably made from stainless steel wire. Stainless steel is renowned for its corrosion resistance, strength, and durability, which make it an outstanding material choice for wire rope hooks. It possesses the ability to endure challenging conditions, including being exposed to water, chemicals, and extreme temperatures, without succumbing to rust or deterioration. Moreover, stainless steel wire exhibits exceptional tensile strength, which is vital for maintaining the safety and integrity of wire rope hooks. Consequently, utilizing stainless steel wire for wire rope hooks guarantees reliability, longevity, and optimal performance.

Send your message to us

Heat-resistant stainless steel fibers melt pumping

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords