Melt Extract Stainless Steel Fiber Reinforced Concrete Wire with Glued Steel Fibers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland), Shandong, China (Mainland)

Model Number: GLUED, glued steel fiber

Material: Steel

type: steel fiber for concrete reinforcement

material: steel wire

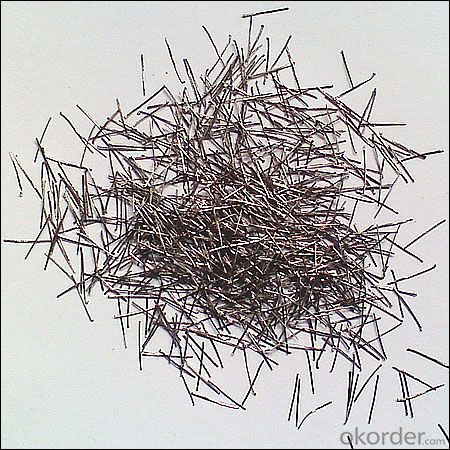

shape: glued together in a row

appearance: clear and bright

Product features

1>steel fiber

2>tensile strength: >1000Mpa

3>wire diameter:0.5mm-1mm

4>standard: ASTM A820

5>20 years factory

hook ends steel fiber, Corrugated steel fiber,Wavy Steel Fiber, steel fiber reinforced, stainless steel fiber, etc.

steel fiber are for concrete construction, greatly improves concrete bonding,etc.

Specifications

length :20-60mm

diameter :0.5MM-1.2MM

tensile strengh:>1100Mpa

| diameter | length | tensile strength | |

| 0.5mm | 35mm | 1100Mpa | |

| 0.75 | 60mm | 1100Mpa | |

| 0.9 | 60m | 1100Mpa |

Picture

PP bag

any type

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

Steel Fiber Glued for Construction and Concrete Wire Diameter

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced polymer (FRP) composites?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced polymer (FRP) composites. The addition of stainless steel fibers enhances the mechanical properties and durability of the composite material, making it suitable for various applications such as construction, automotive, and aerospace industries.

- Q: Is melt extract stainless steel fiber compatible with all types of aggregate?

- Melt extract stainless steel fiber is not universally compatible with all types of aggregate, I'm afraid. The compatibility relies on a variety of factors, including the aggregate's composition, characteristics, and the specific properties and requirements of the application. To achieve the desired performance, it is crucial to carefully consider the bonding, dispersion, and overall effectiveness of the fiber and aggregate combination. Seeking guidance from experts or manufacturers is highly advised to determine the compatibility of melt extract stainless steel fiber with different aggregate types for specific applications.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of rupture of shotcrete?

- The inclusion of melt extract stainless steel fiber in shotcrete can have a significant effect on the modulus of rupture. Modulus of rupture refers to the maximum amount of stress a material can withstand before it fails in a bending or tensile test. The addition of stainless steel fibers in shotcrete increases its tensile strength and flexural performance, leading to an improvement in the modulus of rupture. These fibers act as reinforcement within the shotcrete matrix, enhancing its overall mechanical properties. The stainless steel fibers distribute the stresses within the shotcrete more evenly, preventing the formation and propagation of cracks. This results in a higher modulus of rupture, as the shotcrete can withstand greater bending and tensile forces before failure occurs. Furthermore, the presence of stainless steel fibers also enhances the ductility of shotcrete. Ductility refers to the ability of a material to deform plastically before ultimate failure. The fibers create a bridge-like effect, allowing the shotcrete to deform and absorb energy before reaching its breaking point. This increased ductility further contributes to the improvement in the modulus of rupture. In summary, the incorporation of melt extract stainless steel fiber in shotcrete has a positive impact on the modulus of rupture. It enhances the material's tensile strength, flexural performance, and ductility, resulting in a higher resistance to bending and tensile forces. This makes shotcrete with stainless steel fibers a highly durable and reliable construction material, particularly suitable for applications requiring high strength and structural integrity.

- Q: What is the effect of melt extract stainless steel fiber on the shrinkage and cracking of concrete?

- The effect of melt extract stainless steel fiber on the shrinkage and cracking of concrete is primarily related to its ability to improve the overall tensile and flexural strength of the concrete matrix. When added to concrete, melt extract stainless steel fibers act as reinforcement, reducing the occurrence of shrinkage and cracking. Shrinkage in concrete occurs due to the drying process, causing the concrete to contract and potentially lead to cracks. By adding melt extract stainless steel fibers to the mix, the concrete's tensile strength is enhanced, reducing the likelihood of shrinkage cracks. The fibers act as a network within the concrete, distributing the forces and stresses more evenly, thereby mitigating the potential for shrinkage-related cracking. Additionally, melt extract stainless steel fibers can improve the resistance of concrete to cracking caused by external factors such as temperature changes, heavy loads, or structural movements. These fibers help to reinforce the concrete, increasing its ability to withstand bending and tensile forces, which can ultimately minimize the occurrence of cracking. Moreover, melt extract stainless steel fibers also improve the durability and longevity of concrete structures. By reducing shrinkage and cracking, the fibers contribute to the overall integrity and stability of the concrete, ensuring it can withstand various environmental and load conditions over an extended period. In summary, the addition of melt extract stainless steel fiber to concrete positively affects shrinkage and cracking by enhancing the concrete's tensile strength, reducing the occurrence of shrinkage-related cracks, and improving its resistance to external forces. Ultimately, this results in more durable and long-lasting concrete structures.

- Q: How much is the steel fiber bridge diversion dam using the model and specifications?

- Combined with the construction of the diversion tunnel on the left bank of the power station, the utilization principle, mix proportion design, construction technology, construction quality control and management of the wet sprayed steel fiber concrete are introduced.

- Q: How does melt extract stainless steel fiber improve the mechanical properties of concrete?

- Various mechanisms are responsible for the improvement of concrete's mechanical properties by melt extract stainless steel fiber. Firstly, the inclusion of stainless steel fiber enhances the tensile strength of concrete by bridging cracks that may occur due to shrinkage or external loads. This bridging effect prevents crack propagation and increases the overall tensile capacity of the concrete. In addition, stainless steel fibers act as reinforcement within the concrete matrix, providing increased resistance to bending and flexural stresses. This reinforcement effect helps distribute the load more evenly throughout the concrete, reducing the risk of localized failures and enhancing the overall structural integrity. Furthermore, the high aspect ratio and excellent adhesion of stainless steel fibers to the concrete matrix contribute to improved impact and fatigue resistance. These fibers effectively absorb and dissipate energy during dynamic loading, making the concrete more resistant to cracking and deformation under repeated or sudden loading conditions. Moreover, the corrosion resistance of stainless steel fibers ensures the long-term durability of the concrete. Unlike traditional reinforcement materials like steel bars, stainless steel fibers do not corrode in the presence of moisture and aggressive chemicals. This corrosion resistance extends the service life of the concrete and maintains its mechanical properties over time. To summarize, melt extract stainless steel fiber enhances the mechanical properties of concrete by improving tensile strength, flexural resistance, impact resistance, fatigue resistance, and corrosion resistance. These enhancements result in a more durable and reliable concrete structure capable of withstanding various types of loading and environmental conditions.

- Q: What is the effect of melt extract stainless steel fiber on the creep of concrete?

- The effect of melt extract stainless steel fiber on the creep of concrete can be significant. Creep is the gradual deformation of concrete under a sustained load over time. It is a critical factor to consider in the design and construction of structures, as excessive creep can lead to long-term structural integrity issues. By incorporating melt extract stainless steel fibers into concrete, the creep behavior can be greatly improved. The addition of these fibers helps to enhance the tensile strength and ductility of the concrete matrix. This increased strength and ductility provide better resistance against the deformation caused by creep. The stainless steel fibers act as reinforcement within the concrete, effectively reducing the internal stresses and minimizing the creep deformation. They also help to distribute the load more evenly throughout the concrete, reducing localized stress concentrations that can contribute to creep. Furthermore, melt extract stainless steel fibers have a high resistance to corrosion, which is particularly beneficial in concrete structures exposed to harsh environmental conditions or aggressive chemicals. Corrosion can accelerate the creep process, and the presence of stainless steel fibers helps to mitigate this effect and prolong the service life of the concrete. In conclusion, the addition of melt extract stainless steel fibers to concrete can have a positive impact on the creep behavior. It improves the overall strength, ductility, and resistance to deformation, resulting in a more durable and long-lasting concrete structure.

- Q: How does melt extract stainless steel fiber contribute to crack control in concrete?

- Melt extract stainless steel fiber contributes to crack control in concrete by enhancing the overall tensile strength and flexural toughness of the material. When added to concrete, these fibers disperse uniformly throughout the mixture, creating a three-dimensional reinforcement system. The high tensile strength of stainless steel fiber helps to resist crack propagation and prevent the formation and widening of cracks in the concrete. As the concrete undergoes shrinkage or thermal expansion, the fibers act as a reinforcement network, distributing the applied stress and minimizing the likelihood of crack formation. Additionally, the presence of stainless steel fibers improves the flexural toughness of concrete, enhancing its resistance to bending and impact loads. This is particularly important in applications where the concrete is subjected to heavy loads or dynamic forces, such as industrial floors or pavements. Furthermore, the unique properties of melt extract stainless steel fibers, such as their corrosion resistance and high aspect ratio, contribute to the long-term durability of the concrete structure. Unlike traditional reinforcement methods like steel bars or mesh, stainless steel fibers do not corrode over time, ensuring the structural integrity and crack control capabilities of the concrete remain intact. In summary, melt extract stainless steel fibers play a crucial role in crack control in concrete by enhancing its tensile strength, flexural toughness, and long-term durability. By providing a three-dimensional reinforcement system, these fibers effectively resist crack propagation, distribute stress, and mitigate the formation and widening of cracks, ultimately improving the overall performance and lifespan of the concrete structure.

- Q: Can melt extract stainless steel fiber be used in shotcrete or sprayed concrete?

- Yes, melt extract stainless steel fiber can be used in shotcrete or sprayed concrete. It is commonly used as reinforcement in these applications to improve the strength, durability, and crack resistance of the concrete.

- Q: What is the typical fiber length and diameter of melt extract stainless steel fiber?

- The typical fiber length and diameter of melt extract stainless steel fiber can vary depending on the specific manufacturer and product, but generally, the fiber length ranges from 10 to 25 millimeters, while the diameter ranges from 20 to 50 micrometers.

Send your message to us

Melt Extract Stainless Steel Fiber Reinforced Concrete Wire with Glued Steel Fibers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords