AISI310 Heat Resistant Micro Stainless Steel Wire

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China

Model Number: 304,310,430,446

Material: Stainless Steel, Stainless Steel

Feature: High quality grade

Standard: ASTM A820

Types: Melt Extracted

Length: 25mm/35mm/19mm

Diameter: 0.3mm-0.7mm

Melting Point: Greater than 1500C

Application: Refractory Industry

Package: In cartons then put into pallets.

Production process:

Quality assurance:

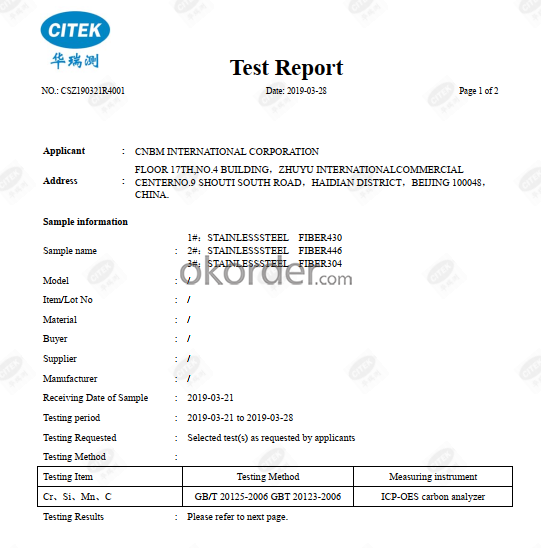

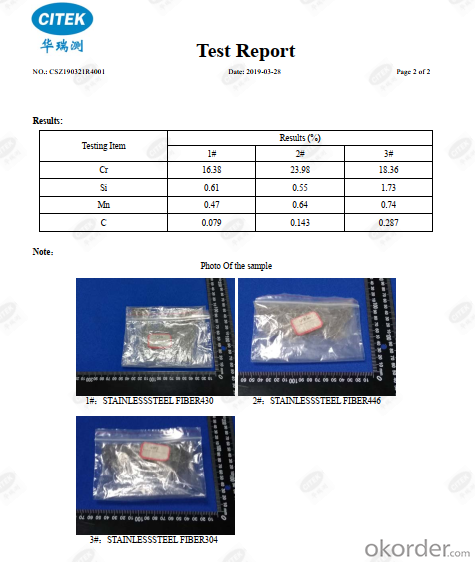

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check the pictures:

Test Report:

- Q: What's the requirements of fire-fighting criteria of heat insulating material?

- Specific provisions go as the following article 8: roof grassroots adopted duration of fire resistance is the non-combustible component that shouldn't less than 1.00 h's. Its roof insulation materials should not be below B2; Otherwise, the combustion performance of insulating material should not be below the B1 level. Article 9: The junction of the roof and wall, the insulation layer around the opening part of roof should use the grade A thermal insulation material to set level fire-fighting belt that width is not less than 500 mm. Article 10: the roof waterproof membrane or flammable insulation layer should adopt incombustible material to cover.

- Q: which kind of material should be used in fireproofing cabinet?

- Natural stone,marble. advantage: Colorful, soft texure, natural and diverse texture, easy to cut or engraving molding. Disadvantages: Because it is a natural formation, tiny loose crackle is easily folded, because the stone is porous material structure, if sewage and waste water permeate in the structure in the process of production, transportation or construction, it's difficult to clean and easy to crack. In daily cleaning, it is inevitable that there will be some residue left, and dirt is filled into crack under the wiping of rag and becomes a breeding ground for bacteria. 2, granite. advantages: Granite has big density and high hardness, with wear-resistant surface, it's one of the most common materials for family decoration. Compared with natural marble, it can be used in the materials of kitchen countertops, and granite has good anti-bacterial regeneration ability. Disadvantages: As the cabinet table material, natural stone is usually not very long, so in order to produce a long overall table (especially U-shaped, L-type table), it will certainly exist joints, which are also easy to hide dirt. 3, artificial stone. advantages: Artificial stone has richful lines and colors, and it can be comparable to stone, it's non-toxic, non-radioactive, easy to clean, and can be truly seamless splicing. it belongs to economic environmentally friendly material. Disadvantages: Artificial stone belongs to the processing industry, and has low technology requirements, The inferior products of many small companys are fulled in the market and damage customers' interests. There exist faded color,poor aging resistance,oil stain and other issues in affordable products.

- Q: What is the function of refractory in ceramics?

- Refractory is used as materials of kiln,sagger and kiln car for ceramic sintering. Its refractoriness is higher than ceramics, and the essential material and tool for ceramic sintering.

- Q: Which fire-resistant materials have good viscidity?

- Viscidity is necessary for gunning mix, repair mix and bordering. It is too broad to which has good viscidity. Both gunning mix and repair mix are powder before adding water. Bordering also has little viscidity before heating. The question shoule be more specific.

- Q: Is aluminium oxide refractory material?

- Calcination aluminium oxide is refractory material of fine performance made from pure aluminium oxide through high-temperature calcination. It can be made into coarse-grained material, fine-grained material, fine powder and micro powder, which can be made into pure jade burnt products. For example, corundum brick, lightweight corundum bricks. It can also be made into a variety of unburning products together with other materials, such as carbonaceous materials. For example, aluminum carbon and aluminium zirconium carbonaceous materials. As for the production of unshaped refractory material, there are more species. It can be corundum, rubing grain, corundum spinel and can also be added into other materials to improve specific performance. It isn't limited to high-alumina castable refractory and it can be castable refractory, ramming?mass, impressionable plastic material, gunning mix and refractory mortar.

- Q: which kind of refractory is commonly used in the industry

- Therefore it is known as special fire-resistant materials, such as yttria, high alumina raw material (sometimes neutral), olivine,which is used for alkalinity furnace, dolomite, and we roughly divided into several categories, beryllia, cerium oxide, these materials have a strong alkaline slag resistance, thorium oxide, lime, serpentine, which is picked from these refractory raw materials. the raw materials of basic refractory materials are mainly magnesia clay and titanium oxide, but because not many sources of raw materials, it can not be widely applied in the refractory industry, and we can analyze which kind of materal is processed by the pulverizer. There are many kinds of refractory materials, rotary?kiln can only be used in particular circumstances. These materials have a variety of slag resistance at different degrees. the main material of special refractories is zirconium oxide. the refractory clay is the most basic and most widely used raw material in the refractory industry.

- Q: Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- Why is the apple screen so small?

- Q: What are fire?ratings of wall thermal insulation material?

- Grade A material has no ignition and is material with thermal insulation effect, anti-combustion material. Currently it mainly refers to inorganic thermal insulation mortars of vitrified micro bead, hole-closed?expanded perlite, rock wool,mineral wool,glass wool,cement base or gypsum base, inorganic thermal insulation mortars and self thermal insulation system of lightweight block. Grade B1 is nonflammable thermal insulation material, which is determined by fire endurance of this material. In addition, the division of the material of different parts is different! What is commonly seen, such as EPS / XPS insulation boards adding flame retardant through special treatment. Grade B2 is combustible thermal insulation materials, and what is commonly seen is EPS expanding polystyrene board and XPS extruded polystyrene board, that is, the general board. This material has low ignition point, and releases large amounts of harmful gases in the combustion process . Grade B3 is flammable insulation material. Thermal insulation material with polyphenyl foam as main material is commonly seen. Since this material is highly flammable, it has been eliminated external wall thermal insulation materials.

- Q: What are the construction fire-proof materials?

- 1. fire?retardant?coating 2. fireproof?panel 3. fire proof and sealing material 4. flame resisting decorative materials 5. Green fire prevention materials

- Q: What's meaning of CN of fire-resistant material?

- The commonly used preparation methodsinclude shock compression, high-pressure pyrolysis, ion implantation, reactive sputtering, plasma chemical vapor deposition, electrochemicaldeposition, ion beam sputtering, , low-energy ion radiation, pulsed arc discharge,pulsed laser inducing, etc. But the compounding result of superhard materialis not ideal due to deposition of amorphous CN film, nanometer level sizedC3N4 crystalline grain set in the amorphous film and few large graincrystal.

Send your message to us

AISI310 Heat Resistant Micro Stainless Steel Wire

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords