HDPE High-Performance Non-Woven Geotextile Fabric for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Non-woven geotextile fabrics are primarily used for projects where highly permeable

separators are required. This includes applications that must allow water to flow while

preventing soil erosion or soil loss.

Applications:We offer a wide range of Non Woven Geotextile Fabrics used while making

Highways and Road Construction. Non Woven Geotextile fabrics are also known as civil

engineering fabrics, erosion control cloth, filter fabrics and support membranes.

RP make Non Woven Geotextile fabrics have their project, structure, or system based on

various geo technical materials such as soils, rock, earth etc. Non Woven Geotextile

fabrics are either used to restrict or allow passage of Water in Slopes and Road

construction, as desired.

The Range of Needle punch Non Woven Geotextile fabrics offered by us are as follows:

Reinforcement

Drainage

Separation

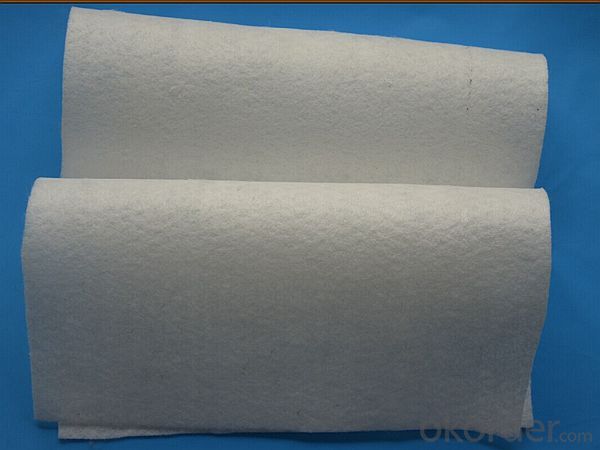

Non Woven Geotextile Product Show:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: What are the specifications for geotextiles in coastal protection projects?

- The specifications for geotextiles in coastal protection projects typically include factors such as the material type, tensile strength, permeability, and UV resistance. Additionally, the specifications may also outline requirements for installation methods and durability to ensure the geotextiles effectively mitigate erosion and provide long-term stability to coastal areas.

- Q: The difference between short wire geotextile and filament geotextile

- Geotextile is a collectively, he includes filament geotextile, short wire geotextile, woven geotextile, woven geotextile, hot pressed nonwovens. Polyester filament geotextile color is mainly white, green. Gray two categories. The length of the fiber is greater than 4.5 cm. Strong strength is very high. Looks very good distinction.

- Q: How do geotextiles prevent soil erosion?

- Geotextiles prevent soil erosion by acting as a barrier that stabilizes the soil and enhances its strength. They are installed in the soil to prevent the movement of soil particles caused by water or wind. The geotextiles allow water to pass through while retaining the soil, thus reducing the velocity of water flow and preventing soil erosion.

- Q: Today someone told me about a boyfriend, said to be geotextile. I wonder, geotextile cloth is what cloth? Is there there? Why is it used More

- Geotextile geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, isolation, reinforcement protection, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Divided into: non-woven geotextile, a textile geotextile (reinforced geotextile), warp knitted geotextile with demand can contact: Fang Lingyan Tel:

- Q: Can the roof waterproof with geotextiles?

- According to personal circumstances, but suggested to find professional personnel assessment. First of all, professional construction, roof waterproofing is a very test of professional skills work, need to hold the local construction administrative departments issued the job certificate. Professional construction units will be detailed survey and roofing drawings. Survey the actual situation of statistics, regional climate, housing and other factors, with the data obtained to develop professional construction program. Construction will be the future may cause housing flaws in the defect to be repaired, so to prevent the future. Secondly, qualified materials, roof leakage in China, about 20% of the material is unqualified, resulting in leakage of the roof of the situation. So in the choice of roof or roof of the material must meet the relevant national standards, and generally qualified roofing materials will have qualified documents and quality inspection departments of qualified certification. In the choice of decoration materials can request the relevant proof, at the same time to check the decoration materials production date, brand, batch number, specifications and so on information to ensure that the quality of qualified roofing materials. Finally, the acceptance of the project, because the roof or roof environment is very complex, so its decoration construction requirements must be strict. The process needs to have a waterproof, leak-proof, anti-seepage function, the summer high temperature can be high temperature, anti-ultraviolet, cold winter to have anti-freeze-resistant low temperature, daily sunshine to have anti-aging and so on.

- Q: What are the advantages of using geotextiles in soil erosion prevention?

- Geotextiles offer several advantages in soil erosion prevention, including increased soil stability, improved drainage, and enhanced filtration. These synthetic materials can effectively reinforce soil, preventing its movement and erosion. Geotextiles also allow water to pass through while trapping sediment, reducing the risk of erosion and maintaining the integrity of the soil. Additionally, they are easy to install and cost-effective, making them a practical solution for erosion control in various applications.

- Q: Can geotextiles be used in the protection of culverts?

- Yes, geotextiles can be used in the protection of culverts. Geotextiles are permeable fabrics that can be placed around culverts to prevent soil erosion and filter out sediments. They provide additional support and stability to the culvert, protecting it from damage and prolonging its lifespan.

- Q: Can geotextiles be used for filtration purposes?

- Yes, geotextiles can be used for filtration purposes. They are specifically designed to allow water to pass through while retaining soil and other particles, making them effective for various filtration applications such as preventing erosion, drainage systems, and sediment control.

- Q: How do geotextiles help with erosion control on coastal cliffs?

- Geotextiles help with erosion control on coastal cliffs by acting as a barrier that prevents the soil from being washed away by the force of waves and rainwater runoff. These synthetic fabrics are placed along the cliff face to stabilize the soil and hold it in place, reducing the impact of erosion. Additionally, geotextiles promote vegetation growth by providing a suitable environment for plants to establish roots, further reinforcing the soil and preventing erosion.

- Q: Can geotextiles be used in the construction of stormwater ponds?

- Yes, geotextiles can be used in the construction of stormwater ponds. Geotextiles are commonly employed in stormwater management systems to enhance filtration, separation, and erosion control. They can be used as a lining material to prevent soil erosion and provide stability to the pond. Additionally, geotextiles can help with sediment control, maintaining water quality, and supporting vegetation growth in stormwater ponds.

Send your message to us

HDPE High-Performance Non-Woven Geotextile Fabric for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords