Geotextile Non Woven HDPE Geonet Civil Engineering Material for Real Estates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Other Earthwork Products

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

CE121

Material:

HDPE

Weight:

730gsm

Width:

2m

Length:

50m

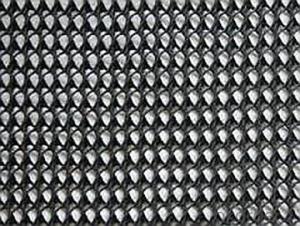

Geonet is a new kind of civil engineering material, it is HDPE products, has the performance of high intensity, lasting chemical stability, weatherproofing ability, anti-corrupt and so on, widely used in construction field. Hereon we only introduce CE131 and CE151, which the most popular geogrids.

HDPE geonet

The application of the geonet:

It is made of high-density polyethylene (HDPE) and the ultravioresistant agent with the property of aging resistance and erosion resistance.

Using the geo-net on the roadbed of the roadway and railway can distribute the load effectively, improve the loading capacity and the stability of the roadway, and prolong its service life.

Spreading the geo-net in the dyke protection in the reservoir and the river can protect it from the landslide.And with the features of good flexibility and strong erosion resistance, using it in the coast engineering can amortize the concussion and the erosion of the surf

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

4.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

5.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

6.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

7.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with sediment control?

- Geotextiles help with sediment control by acting as a barrier that prevents sediment from being washed away or eroded. They stabilize the soil, reduce erosion, and allow water to pass through while trapping sediment particles, thus preventing them from contaminating water bodies.

- Q: Are geotextiles resistant to freeze-thaw cycles?

- Yes, geotextiles are generally resistant to freeze-thaw cycles. They are designed to withstand various environmental conditions, including freezing temperatures and the repetitive expansion and contraction caused by freeze-thaw cycles.

- Q: Under what circumstances drainage pipes need additional geotextiles

- Infiltration of water under the circumstances, geotextile play a filtering effect, Huazhi geotextile material manufacturers

- Q: How much is the geotextile machine?

- Geotextile is very cheap a few hundred dollars, geomembrane is more expensive, 4000-8000 yuan, I specializing in the production of geomembrane geotextile

- Q: what do you mean nonwoven geotextiles ???

- please refer the folowing url to know all the details about non woven geo textiles

- Q: Can geotextiles be used for drainage?

- Yes, geotextiles can be used for drainage. They are commonly used in various drainage applications such as road construction, retaining walls, and landfills. Geotextiles help to enhance the drainage system by allowing water to pass through while preventing the loss of soil particles. They also provide filtration and separation, ensuring optimal drainage performance.

- Q: Manufacture of geotextile machinery

- Non-woven needle machine, I am specializing in the production of geotextiles

- Q: 250 grams of geotextile how much money a square

- 250g geotextile market price of 2.3 yuan a square meter

- Q: Waterproof geotextile market demand prospects?

- Supply geotextile, geomembrane, composite geomembrane and other geotechnical materials. Market prospects are excellent. Geotechnical material manufacturers to answer your questions

- Q: What are the different geotextile puncture resistance test methods?

- There are several different geotextile puncture resistance test methods, including the ASTM D4833 puncture test, ASTM D6241 puncture test, and the ISO 12236 puncture test. These tests involve applying a force to a geotextile specimen using a puncture probe or cone, and measuring the force required to puncture the material. These methods help determine the puncture resistance and durability of geotextiles for various applications.

Send your message to us

Geotextile Non Woven HDPE Geonet Civil Engineering Material for Real Estates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords