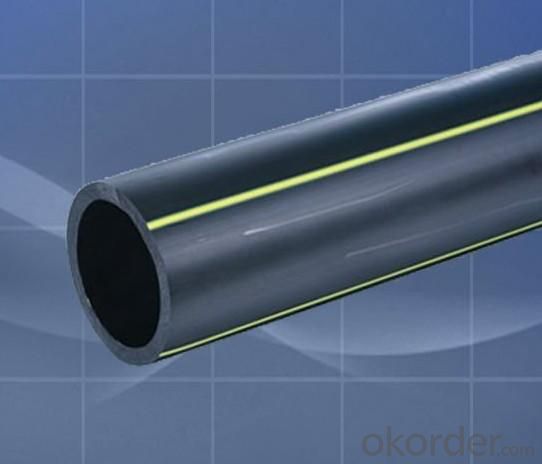

HDPE Gas Composite Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meters m

- Supply Capability:

- 1000000 Meters m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of HDPE Gas Pipe :

Place of Origin | China (Mainland) |

Material | HDPE |

Specification | dn20~dn630 |

Length | 4m,5.8m,11.8m |

Thickness | Standard |

Standard | ISO4427, ISO4437 |

Raw Material | PE80, PE100 |

Color | Black, Blue |

Temperature | -40℃~60℃ |

Product Description of HDPE Gas Pipe:

Material: PE80/ PE100 (mainly PE 100 now).

Sizes: 20mm--630mm

SDR: SDR11, SDR13.6, SDR17, SDR21, SDR26, SDR33

Pressure: 0.4Mpa(PN4), 0.6Mpa(PN6), 0.8Mpa(PN8), 1.0Mpa(PN10), 1.25Mpa(PN12.5), 1.6Mpa(PN16)

Color: Black or others on request

Connection: Socket-fusion jointed, butt-fusion jointed , electron-fusion jointed, flange jointed

Standard: ISO4427, ISO4437, GB/T 13663-2000

Certification: ISO9001, ISO14001

Application: Water supply, Industries liquids transportation , sewage conduit

Identifies: black water pipe identifies the color at least three blue stripes, and evenly distributed along the pipe circumference

Advantage of HDPE Gas Pipe:

1. Non-toxic, no heavy metal additives, no fouling, not breed bacterium,

2. Corrosion resistant: PE is inert material and it can resist the corrosion of many chemical mediums, or electron chemical corrosion. except for few strong oxidants

3. High strength, good performance to resist the environmental stress cracking, good creep resistance.

4. Good flexibility: small diameters, PE pipe for water supply can be coiled and supplied for longer length, which saves a large number of fittings, PE pipe can be easily shifted according to requirement of the projects.

5. Light weight, simple safe and reliable welding technique, convenient construction and lower cost of the whole engineering,

6. Smooth interior wall, small water resistance, high flow capacity,

7. Long service life, up to 50 years under normal conditions.

8. Recyclable, benefit to the environment

- Q: Can composite pipes be used for hydroelectric power generation?

- Yes, composite pipes can be used for hydroelectric power generation. Composite materials like fiberglass or carbon fiber reinforced polymers offer high strength-to-weight ratios, corrosion resistance, and durability, making them suitable for transporting water in hydroelectric power systems. These pipes can effectively handle the high pressure and flow rates required for efficient power generation. Additionally, composite pipes are lightweight and easier to install compared to traditional metallic pipes, reducing costs and improving overall system performance.

- Q: How do composite pipes handle seismic movements?

- Composite pipes are designed to handle seismic movements by being flexible and strong. The combination of materials, such as fiber-reinforced polymers, allows the pipes to withstand ground shaking without significant damage or rupture. The flexibility of composite pipes allows them to bend and absorb the seismic energy, reducing the risk of failure during earthquakes. Additionally, the strong reinforcement helps maintain the structural integrity of the pipes, ensuring their long-term performance even in high seismic activity areas.

- Q: Do composite pipes require anchoring or support in certain applications?

- Yes, composite pipes often require anchoring or support in certain applications to ensure their stability and prevent unnecessary stress or damage.

- Q: What are the different types of composite pipes available?

- There are several different types of composite pipes available, including fiberglass reinforced plastic (FRP) pipes, carbon fiber reinforced polymer (CFRP) pipes, and reinforced thermoplastic pipes (RTP). Each type has unique properties and advantages, such as high strength, corrosion resistance, and lightweight design, making them suitable for various applications in industries such as oil and gas, water supply, and construction.

- Q: Do composite pipes have a higher flow capacity compared to metal pipes?

- Yes, composite pipes generally have a higher flow capacity compared to metal pipes. This is because composite pipes are typically lighter in weight, smoother in surface finish, and have a higher resistance to corrosion, which allows for smoother flow and less friction loss.

- Q: How does a composite pipe differ from a traditional metal pipe?

- A composite pipe differs from a traditional metal pipe primarily in its construction material. While a traditional metal pipe is made entirely of metal, a composite pipe is typically composed of multiple layers of different materials. This combination of materials gives a composite pipe several advantages over a traditional metal pipe, such as improved resistance to corrosion, reduced weight, and enhanced flexibility. Additionally, composite pipes often have better insulation properties and can be more cost-effective in certain applications.

- Q: Can composite pipes be used for underground oil storage?

- Yes, composite pipes can be used for underground oil storage. Composite pipes are known for their corrosion resistance, strength, and durability, making them suitable for storing oil underground. Additionally, composite pipes are lightweight and easily transportable, reducing installation costs and time. However, it is important to ensure that the composite pipes used for underground oil storage meet all safety and regulatory requirements.

- Q: Are composite pipes suitable for hydroelectric power plants?

- Yes, composite pipes are suitable for hydroelectric power plants. Composite pipes offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them well-suited for the challenging environment of hydroelectric power plants. These pipes can handle the high pressures and flow rates required for water conveyance and are less prone to leakage or degradation over time. Additionally, their non-conductive nature reduces the risk of electrical accidents in a facility that generates and transmits electricity.

- Q: Do composite pipes have any insulating properties?

- Composite pipes do have insulating properties due to the materials used in their construction. The combination of different materials in composite pipes helps to reduce heat transfer, thereby providing insulation.

- Q: Are composite pipes resistant to chemicals?

- Yes, composite pipes are highly resistant to a wide range of chemicals.

1. Manufacturer Overview

| Location | Wuhan,China |

| Year Established | 1986 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | Southeast Asia Africa Oceania Mid East Eastern Asia |

| Company Certifications | ISO9001-2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wuhan |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | Above 50 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered;Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

HDPE Gas Composite Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meters m

- Supply Capability:

- 1000000 Meters m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords