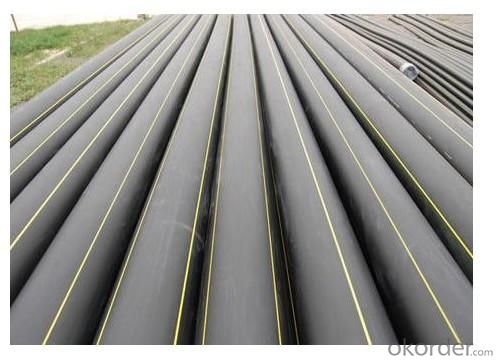

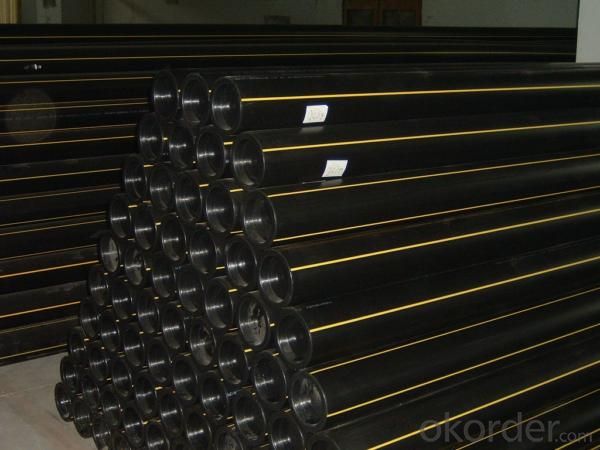

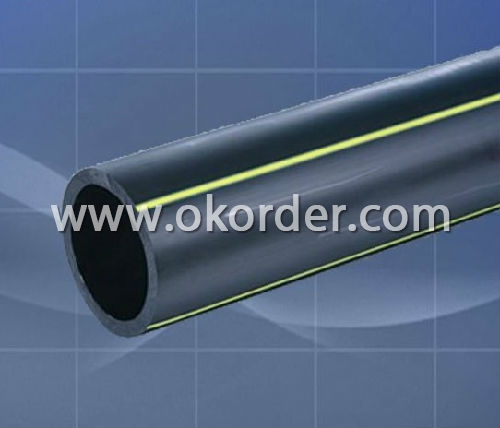

Composite PE Gas Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meters m

- Supply Capability:

- 1000000 Meters m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of PE Gas Pipe :

Place of Origin | China (Mainland) |

Material | HDPE |

Specification | dn20~dn630 |

Length | 4m,5.8m,11.8m |

Thickness | Standard |

Standard | ISO4427, ISO4437 |

Raw Material | PE80, PE100 |

Color | Black, Blue |

Temperature | -40℃~60℃ |

Product Description of PE Gas Pipe:

Material: PE80/ PE100 (mainly PE 100 now).

Sizes: 20mm--630mm

SDR: SDR11, SDR13.6, SDR17, SDR21, SDR26, SDR33

Pressure: 0.4Mpa(PN4), 0.6Mpa(PN6), 0.8Mpa(PN8), 1.0Mpa(PN10), 1.25Mpa(PN12.5), 1.6Mpa(PN16)

Color: Black or others on request

Connection: Socket-fusion jointed, butt-fusion jointed , electron-fusion jointed, flange jointed

Standard: ISO4427, ISO4437, GB/T 13663-2000

Certification: ISO9001, ISO14001

Application: Water supply, Industries liquids transportation , sewage conduit

Identifies: black water pipe identifies the color at least three blue stripes, and evenly distributed along the pipe circumference

Advantage of PE Gas Pipe:

1. Non-toxic, no heavy metal additives, no fouling, not breed bacterium,

2. Corrosion resistant: PE is inert material and it can resist the corrosion of many chemical mediums, or electron chemical corrosion. except for few strong oxidants

3. High strength, good performance to resist the environmental stress cracking, good creep resistance.

4. Good flexibility: small diameters, PE pipe for water supply can be coiled and supplied for longer length, which saves a large number of fittings, PE pipe can be easily shifted according to requirement of the projects.

5. Light weight, simple safe and reliable welding technique, convenient construction and lower cost of the whole engineering,

6. Smooth interior wall, small water resistance, high flow capacity,

7. Long service life, up to 50 years under normal conditions.

8. Recyclable, benefit to the environment

- Q: How do composite pipes compare to steel pipes in terms of strength?

- Composite pipes are generally stronger than steel pipes. This is because composite pipes are made by combining materials, such as fiberglass or carbon fiber, with a polymer matrix, which results in a high strength-to-weight ratio. Steel pipes, on the other hand, have a high tensile strength but can be heavy. Composite pipes offer comparable strength while being lighter, making them a preferred choice in various applications.

- Q: Are composite pipes resistant to UV degradation?

- Yes, composite pipes are generally resistant to UV degradation. The materials used in composite pipes, such as fiberglass or carbon fiber, are inherently resistant to UV radiation. Additionally, composite pipes are often coated with protective layers or additives that further enhance their UV resistance. However, it is important to note that the specific composition and manufacturing process of each composite pipe can vary, so it is advisable to consult the manufacturer's specifications for precise UV resistance information.

- Q: Can composite pipes be used for oil and gas pipelines?

- Yes, composite pipes can be used for oil and gas pipelines. They offer several advantages such as corrosion resistance, high strength-to-weight ratio, and improved durability, making them suitable for various applications in the oil and gas industry. Composite pipes also provide better flow characteristics, reduced installation costs, and increased resistance to external factors, making them an effective choice for oil and gas transportation.

- Q: Can composite pipes be used for landfills and waste management?

- Yes, composite pipes can be used for landfills and waste management. Composite pipes are known for their strength, durability, and resistance to corrosion, making them suitable for transporting and managing various types of waste materials. Additionally, composite pipes are lightweight, easy to install, and have a longer lifespan compared to traditional materials, making them a reliable and cost-effective solution for landfill and waste management systems.

- Q: Are composite pipes resistant to impact or abrasion?

- Yes, composite pipes are highly resistant to impact and abrasion.

- Q: What is the definition of flexible pipes in FRP composite pipes?

- Another feature is scalability, which can be designed to be very elegant, with different production methods or different workstation applications. Flexible tube in flexibility is also very excellent, and its production process has been constantly adjusted, in the construction can be adapted to different on-site changes in the process. Glass fiber reinforced plastic composite pipe is an ideal product to replace stainless steel pipe, and is different in appearance and color.

- Q: What does "aluminum plastic composite pipe" 1216-l mean?

- Aluminum plastic composite pipe has better thermal insulation performance, internal and external wall is not easy to corrosion, because the inner wall is smooth, the fluid resistance is very small, and because it can bend freely, so the installation and construction is convenient. As the water supply pipeline, the aluminium plastic composite pipe has enough strength.

- Q: Are composite pipes resistant to seismic activity?

- Yes, composite pipes are generally resistant to seismic activity. Their high strength and flexibility make them less prone to damage from ground movement during earthquakes compared to traditional materials like metal or concrete. Additionally, composite pipes offer excellent corrosion resistance, which further enhances their durability and ability to withstand seismic activity.

- Q: What is called PSP steel plastic composite pressure pipe, the connection mode or the expansion type?! The big caliber is the flaring joint!

- PSP steel plastic composite pressure pipe is steel wire mesh, polyethylene composite pipe or hole net steel tape polyethylene composite pipe.

- Q: How do composite pipes perform in extreme weather conditions?

- Composite pipes perform exceptionally well in extreme weather conditions. They are designed to withstand a wide range of temperatures, from extremely cold to scorching hot, without any significant impact on their performance. The composite material used in these pipes is highly resistant to corrosion, UV rays, and other environmental factors. This enables them to maintain their structural integrity and functionality even in harsh weather conditions, ensuring that they continue to deliver efficient and reliable performance.

1. Manufacturer Overview

| Location | Wuxi,China |

| Year Established | 1998 |

| Annual Output Value | US$1.5 Million - US$2 Million |

| Main Markets | South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia |

| Company Certifications | NONE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered;Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Composite PE Gas Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meters m

- Supply Capability:

- 1000000 Meters m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords