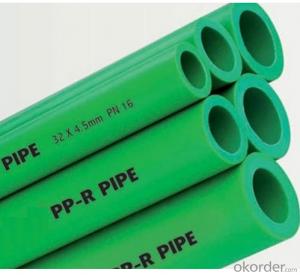

Composite PPR Pipes for Hot and Cold Water

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Meters m

- Supply Capability:

- 50000 Meters per Day m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ppr Pipe For Hot And Cold Water

Size: 20-75 mm

15 years produce experience

Certificate: CE; ISO9001

Features of Ppr Pipe For Hot And Cold Water:

Sizes: 20 to 75mm

Pressure: PN1.25Mpa; PN1.6Mpa; PN2.0Mpa; PN2.5Mpa

Colors: Light grey, white or other colors on request

Connection: Welding

Certification: CE, ISO9001

Advantages of Ppr Pipe For Hot And Cold Water:

High Temperature Resistance: the maximum sustained working temperature is up to 70 °C,the maximum transient temperature is up to 95°C

Heat Preservation: low thermal conductivity which is only 1/1500 of brass pipe. And 1/250 of steel pipe.

Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium.

Corrosion Resistant: resist chemical matters or electron chemical corrosion.

Lower Installation Costs: light weight and ease of installation can reduce installation costs by as much as 50%over metal piping system.

Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

Long Life: more than 50 years under normal conditions

- Q: Can composite pipes be used for underground fuel storage?

- Yes, composite pipes can be used for underground fuel storage. Composite materials, such as fiberglass reinforced plastic (FRP) pipes, offer high strength, corrosion resistance, and durability, making them suitable for storing fuel underground. These pipes are lightweight and can withstand harsh environmental conditions, ensuring the safety and integrity of the fuel storage system. Additionally, composite pipes are non-conductive, reducing the risk of electrical hazards.

- Q: Can composite pipes be used for chemical storage systems?

- Yes, composite pipes can be used for chemical storage systems. Composite materials such as fiberglass reinforced plastic (FRP) offer excellent resistance to corrosion, making them suitable for storing a wide range of chemicals. These pipes are lightweight, durable, and have a longer lifespan compared to traditional materials, making them a preferred choice for chemical storage applications.

- Q: Is the water pipe in the house made of PPR pipe or stainless steel pipe? What brand is better?

- To the building materials City, you will find, water pipes are dazzling, PP-R pipe, PVC-U pipe, lining plastic pipe, stainless steel pipe, copper pipe and so on.The water pipe should be stable, watertight, and free from burstingWhat we call safety and durability is the occurrence of accidents that endanger life and family safety in the service life of the water pipe, which can not be used for a long time.

- Q: Can composite pipes be used for wastewater treatment plants?

- Yes, composite pipes can be used for wastewater treatment plants. Composite pipes, which are made from a combination of different materials such as fiberglass and resin, have several advantages for wastewater applications. They are corrosion-resistant, lightweight, and have a long lifespan, making them suitable for the harsh and corrosive environment of wastewater treatment plants. Additionally, composite pipes offer excellent hydraulic properties, low friction losses, and are easy to install, making them a cost-effective choice for wastewater treatment plants.

- Q: What types of materials are used to make composite pipes?

- Composite pipes are typically made using a combination of materials such as fiberglass, carbon fiber, or other reinforcing fibers, along with a polymer matrix such as epoxy or thermoplastic. These materials are chosen for their strength, durability, and resistance to corrosion, making composite pipes an excellent choice for various industries and applications.

- Q: Steel plastic composite pipe, hot galvanized steel pipe, the mechanism of cast iron pipe, plastic pipe, which need to brush oil rust?

- When the factory has made rust treatment, the cast iron pipe surface is also out of the factory when the paint brush, so it does not need.

- Q: What is the thermal conductivity of composite pipes?

- The thermal conductivity of composite pipes can vary depending on the materials used in the composite. However, composite pipes generally have lower thermal conductivity compared to traditional metallic pipes.

- Q: Can composite pipes be used for hot water systems?

- Yes, composite pipes can be used for hot water systems. Composite pipes, typically made from a combination of materials like fiberglass, plastic, and aluminum, offer excellent resistance to high temperatures, corrosion, and pressure. They are lightweight, cost-effective, and have good thermal insulation properties, making them suitable for hot water systems.

- Q: Are composite pipes suitable for chemical refineries?

- Yes, composite pipes are suitable for chemical refineries. They offer excellent resistance to corrosion, abrasion, and chemicals, making them ideal for transporting various corrosive fluids in refineries. Additionally, composite pipes are lightweight, easy to install, and require minimal maintenance, ensuring efficient and reliable operations in chemical refineries.

- Q: Are composite pipes suitable for use in desalination plants?

- Yes, composite pipes are suitable for use in desalination plants. Composite pipes offer several advantages such as excellent resistance to corrosion, durability, and high strength-to-weight ratio, making them ideal for the harsh conditions and high-pressure requirements of desalination plants. Additionally, composite pipes have lower maintenance costs and longer lifespan compared to traditional materials like steel or concrete, making them a reliable choice for desalination plant applications.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | CE;ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Composite PPR Pipes for Hot and Cold Water

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Meters m

- Supply Capability:

- 50000 Meters per Day m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords