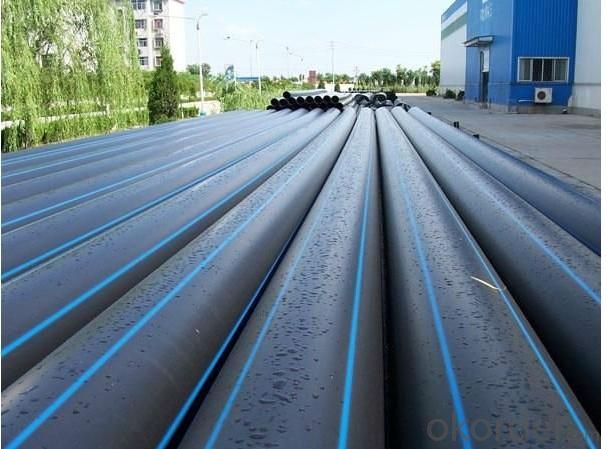

HDPE Composite Water Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meters m

- Supply Capability:

- 1000000 Meters m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of HDPE Water Pipe

Material: PE80/ PE100 (mainly PE 100 now).

Sizes: 20mm--630mm

SDR: SDR11,SDR13.6,SDR17,SDR21,SDR26,SDR33

Pressure: 0.4Mpa(PN4), 0.6Mpa(PN6), 0.8Mpa(PN8), 1.0Mpa(PN10), 1.25Mpa(PN12.5), 1.6Mpa(PN16)

Color: Black or others on request

Connection: Socket-fusion jointed, butt-fusion jointed , electron-fusion jointed, flange jointed

Standard: ISO4427, ISO4437, GB/T 13663-2000

Certification: ISO9001, ISO14001

Application: Water supply, Industries liquids transportation , sewage conduit

Identifies: black water pipe identifies the color at least three blue stripes, and evenly distributed along the pipe circumference

Advantage of HDPE Water Pipe

1.Non-toxic, no heavy metal additives, no fouling, not breed bacterium,

2.Corrosion resistant: PE is inert material and it can resist the corrosion of many chemical mediums,

or electron chemical corrosion. except for few strong oxidants

3.High strength, good performance to resist the environmental stress cracking, good creep

resistance.

4.Good flexibility: small diameters PE pipe for water supply can be coiled and supplied for longer

length, which saves a large number of fittings , PE pipe can be easily shifted according to

requirement of the projects.

5.Light weight ,simple safe and reliable welding technique,convenient construction and lower cost

of the whole engineering,

6.Smooth interior wall, small water resistance, high flow capacity,

7.Long service life :up to 50 years under normal conditions.

8.Recyclable, benefit to the environment

- Q: Are composite pipes more expensive than traditional pipes?

- Yes, composite pipes are generally more expensive than traditional pipes due to their advanced materials and manufacturing processes.

- Q: Can composite pipes be used for underground heating systems?

- Yes, composite pipes can be used for underground heating systems. Composite pipes, made from materials such as PEX (cross-linked polyethylene) and aluminum, are commonly used for their durability, flexibility, and resistance to corrosion. They are suitable for underground installations as they can withstand the high temperatures and pressures associated with heating systems while maintaining their structural integrity.

- Q: Do composite pipes have a smooth exterior surface?

- Yes, composite pipes typically have a smooth exterior surface.

- Q: How do composite pipes handle cyclic loading?

- Composite pipes handle cyclic loading by distributing the stress evenly throughout the pipe structure, which helps to prevent fatigue and failure. The unique combination of materials used in composite pipes, such as fiberglass and resin, provides high strength and flexibility, allowing the pipe to withstand repeated stress without significant damage. Additionally, the composite materials used in these pipes are resistant to corrosion, making them suitable for various applications in industries such as oil, gas, and water transportation.

- Q: Can the steel skeleton composite pipe and the air net steel belt compound pipe be connected together?

- The nominal two composite pipe diameter is different, therefore, can not be directly welded, the best way is to use the flange connection, if must use electric welding, can be increased diameter composite tube diameter is relatively small, and then through the electric melting welding.

- Q: What is the difference between steel plastic composite pipe and lining plastic pipe? How much is the price difference?

- Steel plastic composite pipe is known, divided into plastic composite pipe and plastic composite pipe. Two different craft products, is plastic composite pipe is a plastic powder coating and lining up, plastic pipe is the first plastic and steel tube processing with good again. We are the Jinzhou pipeline company, specializing in the production of steel plastic composite pipe.

- Q: Can steel wire mesh composite pipe sleeve HDPE Double wall corrugated pipe be fixed?

- If the maintenance works, you can see if there's a pipe repair quota item, such as there is to apply. If there is no, you can apply the pipeline quota to see whether the quota content is not the same, if it is too large, you can cancel the quota content conversion.

- Q: Can composite pipes be used for oil and gas transportation?

- Yes, composite pipes can be used for oil and gas transportation. Composite pipes, made from materials such as fiberglass and carbon fiber, offer several advantages over traditional metal pipes. They are lightweight, corrosion-resistant, and have excellent mechanical properties. These pipes can withstand high pressure and temperature conditions, making them suitable for oil and gas transportation. Additionally, composite pipes have low friction coefficients, reducing energy loss during transportation.

- Q: What is the difference between aluminum plastic composite pipe and aluminum plastic PPR pipe?

- Pipe is widely used. Pipes are used in many industries.Different industries have different characteristics of the industry, and thus have different technical requirements.Pipe is a relatively mature product, each industry has the corresponding technical standards.Detect pipe material, according to the application of pipe industry, select the corresponding product standards, according to the industry needs to detect the corresponding technical indicators.

- Q: What is the plastic lined composite pipe?

- The utility model has the advantages of mechanical property of the steel pipe and corrosion resistance of the plastic pipe, slow scaling and difficult growth of microorganisms, and can transport acid, alkali, salt, corrosive gas and other mediums.

1. Manufacturer Overview

| Location | Wuhan,China |

| Year Established | 1986 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | Southeast Asia Africa Oceania Mid East Eastern Asia |

| Company Certifications | ISO9001-2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wuhan |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | Above 50 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered;Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

HDPE Composite Water Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meters m

- Supply Capability:

- 1000000 Meters m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords