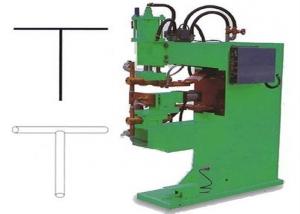

NEW DODO-600 Fully automatic can body welder

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

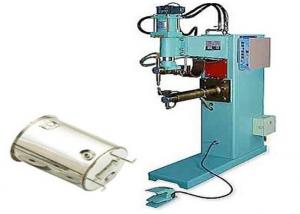

NEW DODO-600 is the automatic can body weldingmachine specially designed to manufacture the metal can body. Adopting themodern electronic technology to completely realize mechanical and electricalintegration, which consists of can round forming, welding and coating in amachine.

Main Features:

1.Equipped with the most advanced man-computer interfacedevice, the whole operation can be made on the touch screen.

2.Equipped with Schneider Electric ControlSystem for all electrical elements and Servo Motor Control System.

3.Equipped with adjustable electronic staticinverter power supply.

4.Equipped with failure self-detected system,system arlarms automatically and provides the solution proposal.

5. With4G remote access control function, the device for remote troubleshooting andreal-time production monitoring

6.Equipped with copper-wire profiling roller inceramic, improve the insulation quality and lower the consumption.

7.Equipped with the very durable ceramic unit onthe can conveying system to reduce wear out.

8.Equipped with the standard mercury lowerwelding roller, non-mercury welding roller also available as a option.

9.Lower welding arm available for both internalpowder coating and internal lacquer spraying coating with Nordson pump.

10.Induction oven is available for the can line,it is able to save over 90%of energy when comparing to the gas oven.

11.Rolling coating or spraying coating is foryour option for outside coating.

Technical Specification

Welding speed | 80m/min(max) |

Production speed | Max. 650cans/min |

welding points distance | 0.5~0.85mm |

Overlap | 0.20~0.4mm |

Sheet thickness | 0.14~0.28mm |

Can inner diameter | ¢52~¢99mm |

Can height | 50~150mm |

Material | Tinplate,Ni plate |

Tin coating | Tin 5#~100# |

Hardness | T2.5~DR8 |

Copper wire | ¢1.20~1.38mm |

Power supply | Three phase Voltage:380V |

Frequency:50Hz Power consumption:45Kw | |

Welding frequency | 250~850Hz |

Cooling water | >0.4MPa , ≤20℃, 720L/min |

Compressed air | >800L/min , >0.5MPa |

- Q: What is the influence of the cooling rate after welding on the mechanical properties of the weld?

- 1 eliminate the internal stress of joints and structures and reduce the tendency to list. 2 improve the microstructure and properties of the joints

Send your message to us

NEW DODO-600 Fully automatic can body welder

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches