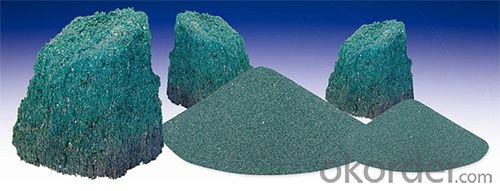

High Purity Green Silicon Carbide - Low Price Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | 1) 25kg woven bag,40 woven bags/jumbo bag. 2) 25kg woven bag,40 woven bags/pallet 3) 25kg paper bag,40 paper bags/pallet 4) 25kg paper bag,40 paper bags/paper box |

| Delivery Detail: | 10DAYS AFTER CONFIRMATION ORDER |

Specifications

F220 High purity SiC

Professional manufacturer

Passed REACH ,ISO-9001:2008

We provide the best quality C in china with high tech testing instrument gurantee the quality.

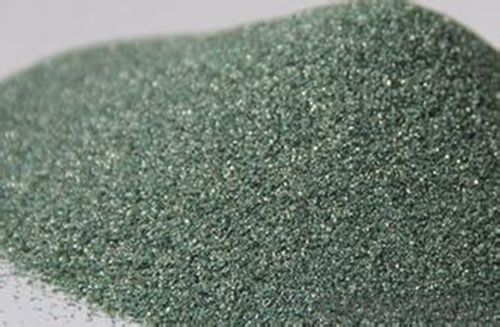

Grinding Black Silicon Carbide

Black silicon carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke as its main raw materials. It is used for making bonded and coated abrasive tools, grinding metal and non-metal materials of lower tensile strength, such as gray cast iron yellow bronze,aluminum, stone, leather, rubber, etc.

Chemical Compsition (%)

Grit | Sic | F.C. | Fe2O3 |

F12-F90 | ≥98.50 | <0.20< span=""> | ≤0.60 |

F100-F150 | ≥98.00 | <0.30< span=""> | ≤0.80 |

F180-F220 | ≥97.00 | <0.30< span=""> | ≤1.20 |

F230-F400 | ≥96.00 | <0.40< span=""> | ≤1.20 |

F500-F800 | ≥95.00 | <0.40< span=""> | ≤1.20 |

F1000-F1200 | ≥93.00 | <0.50< span=""> | ≤1.20 |

P12-P90 | ≥98.50 | <0.20< span=""> | ≤0.60 |

P100-P150 | ≥98.00 | <0.30< span=""> | ≤0.80 |

P180-P220 | ≥97.00 | <0.30< span=""> | ≤1.20 |

P230-P500 | ≥96.00 | <0.40< span=""> | ≤1.20 |

P600-P1500 | ≥95.00 | <0.40< span=""> | ≤1.20 |

P2000-P2500 | ≥93.00 | <0.50< span=""> | ≤1.20 |

Physical Index

Grits | Bulk Density | High Density | Grits | Bulk Density | High Density |

F16 ~ F24 | 1.42~1.50 | ≥1.50 | F100 | 1.36~1.45 | ≥1.45 |

F30 ~ F40 | 1.42~1.50 | ≥1.50 | F120 | 1.34~1.43 | ≥1.43 |

F46 ~ F54 | 1.43~1.51 | ≥1.51 | F150 | 1.32~1.41 | ≥1.41 |

F60 ~ F70 | 1.40~1.48 | ≥1.48 | F180 | 1.31~1.40 | ≥1.40 |

F80 | 1.38~1.46 | ≥1.46 | F220 | 1.31~1.40 | ≥1.40 |

F90 | 1.38~1.45 | ≥1.45 |

Size Available

F12-F1200,P12-P2500

0-1mm,1-3mm,6/10, 10/18, ,200mesh,325mesh

Other special spec. could be supplied as required.

- Q: What are the meanings of azs, 34% and ec in fused brick?

- The fused brick, also called zircon corundum brick, is shorted as AZS for three chemical components in Al2O3-ZrO2-SiO2 ternary diagram. I don't know the meaning of EC.

- Q: Who can introduce the difference between galvanized fireproof?coatings and steel structure fireproof materials?

- Steel structure with heat galvanization has a process requirement, which is to spray fireproof coatings. Fireproof coatings have different functions and purposes from galvanized process. When the steel surface derusted, it generally needs to brush rich-zinc primer before spraying fireproof coating. Fireproof coating plan itself includes anticorrosion plan, and fireproof coating is just a layer of coating plans, which is an intermediate layer in general. Fireproof coating plan generally includes primer, fireproof coating and finishing paint. Some fireproof coatings can be directly painted on the bare steel elements without primer and finishing paint.

- Q: What are the requirements of the performances of brasque refractory?

- Physical properties of refractories include structural property, thermal property, mechanical property, usability and operation property. Structural properties of refractories include porosity, bulk density, water absorption, air permeability, pore size distribution,etc.. Refractory thermal properties include thermal conductivity, thermal expansion coefficient, specific heat, heat capacity, thermal diffusivity, thermal emissivity. Mechanical properties of refractories include compression strength, tensile strength, breaking strength, torsional strength, shear strength, impact strength, abrasion resistance, creep property, bonding strength, elasticity modulus. usabilities of refractories include refractoriness, refractoriness under load, reheating linear change, thermal shock resistance, slag resistance, acid resistance, alkali resistance, water resistance, corrosion resistance to CO, conductivity, oxidation resistance, etc.. Operation properties of refractory include consistence, slump, fluidity, plasticity, cohesiveness, resilience, coagulability and hardenability,etc. I hope you can solve the problem with my answer.

- Q: Is there vermiculite in refractory?

- Paint, small thermal conductivity, chemical, shipbuilding and other industries. Expanded vermiculite has excellent electrical?insulating?property, and it is stratified structure. It is a good thermal insulation material used in growing seedings, flowers and trees, bulidings, rubber and smelting. I hope my answer will make you satisfied. Refractory contains crystal water and board between its layers. For example, the interlayer of fireproof door contains expanded vermiculite, and after expansion, its specific gravity is 60-180kg& # 47. Electric insulation material. Expanded vermiculite is widely used for thermal?insulation?material and sealing material. Of course, some refractory also uses vermiculite; fireproofing material. Vermiculite is a good refractory material, whose maximum using temperature and unit weight can be repsectively up to 1,100 ℃ and 50-200kg/m3. When it is expanded, it is called expanded vermiculite. It is highly thermal insulated. Hard water softeners and paint. After unripe flake vermiculite is roasted in high temperature, its volume will expand 6- 20 times quickly. Friction materials, its volume can be quickly expanded several times to dozens of times. In addition. Quality expanded vermiculite

- Q: How long is the fire resistance time of the AAAfire resistance rolling shutter door?

- How long is the fire resistance time of the AAA fire resistance rolling shutter door?

- Q: I want to know what is the slim in the refractory bricks

- lining brick and refractory clay in the teeming ladle; high alumina brick, high alumina lining brick and high alumina refractory mortar can make cement kiln and glass melting furnace in the building materials industry for anti-slide. Taiyuan in Shanxi province is the famous place of origin; hard paste in the refractory clay is used as blast furnace refractory: // b, in agriculture as a fertilizer high alumina clay is also used in oil wells, which generally do not dip in water; accounting for 2/3 of abrasive products in the metallurgy, hard and semi-hard clay can be manufactured as ceramics for daily use. what you said should be slime. High-alumina clay can be resistant to high temperature after calcination! Refractoriness refractory clay refers that the refractoriness is more than 1580 ℃ with greater hardness and specific gravity and high refractoriness. except higher refractoriness, such as aluminum sulfate, the dosage accounts for about 70% of refractories; refractory clay and high alumina fused cast brick are widely distributed in China.

- Q: Why do magnesium oxide refractory bricks can be made into refractories?

- Because the magnesium oxide, commonly known as magnesia, which is a basic oxide, with the common property of alkali oxides and belongs to the cementitious material . It is white or light yellow powder, odorless, tasteless, non-toxic and a typical of alkaline earth metal oxide, whose chemical formula is MgO. It is white powder, with melting point of 2852 ℃, boiling point of 3600 ℃ and relative density of 3.58 (25 ℃). The magnesium oxide that is soluble in acid and ammonium hydroxide solution has high insulation properity. After high temperature of above 1000 ℃ burning, it will transform into crystals, and when rising above 1500 ℃ , it will turn into dead-burned magnesium oxide (also known as the magnesia) or sintered magnesia. So the performance of magnesium oxide refractory bricks is good, and the fire resistance of it is very strong.

- Q: What refractory material does cupola lining use?

- In order to improve the service life of the lower wall and the bottom leather, dense and high alumina brick can be used for masonry. The front furnace is composed of the bottom, the wall and the top. The top of the furnace is vaulted or hanging flat roof. The front furnace body is usually made of clay brick and high alumina brick, and the bottom work floor is rammed with ramming material. The material is the same as that of cupola furnace. The bridge and the front guard taphole, slag hole and other parts due to erosion by high temperature molten iron and slag erosion, lower service life, frequent repairs. Large blast furnace adopts hot blast or oxygen enriched blast, which has higher temperature and higher production capacity... The damage is faster, and it is hard to maintain production by using clay brick or high alumina brick. Should be used aluminum, carbon or corundum refractory silicon carbide castables pouring or tamping, so that the integrity of good, high strength, corrosion resistance, and therefore significantly improved service life, generally up to one year or so. Refractory materials, including chimneys and spark traps, are used in other parts of the cupola. The chimney and the cupola shaft directly connected with the shell made of steel plate, lined with ordinary clay brick, can also be used ordinary refractory castable pouring. The chimney is provided with a furnace heat exchanger, which can preheat the air to 300~500 DEG C, and the spark collector is used for catching the hot coke and dust particles brought out in the flue gas. The chimney at the top of the reflector (cover) by plate welding, can also be used to cast iron, its lining refractory coating or spraying paint.

- Q: Firing high temperature kiln of refractory and internal temperature being as high as 1600 ℃, metal heat exchanger can't use, how to do?

- 1>3>。 When metal heat exchanger is in 700 ℃, it must process high temperature protection, mixed cold wind or cold blast to protect heat exchanger. So this will waste a lot of energy; The comparison of high temperature resistant ceramic heat exchanger using temperature is 1350 ℃ to 1450 ℃; metal heat exchanger using temperature 700 ℃; heat utilization comparison of ceramic heat exchanger can be placed in 1350 ℃ or higher (highest available to 1450 ℃); the oxidation resistance, a very short time will burn out;2 >, waste heat recovery rate is high. Replacing the metal heat exchanger in high temperature and corrosion environment; Comparative ceramic heat exchanger can be used under the condition of 1350 ℃ for a long time. Let's make a comparison, if it is a refractory material industry. <, ceramic heat exchanger is simply won't appear, under the condition of equal to ceramic heat exchanger using, energy saving effect is best, can exchange for the high temperature. <. Ceramic heat can be placed on the nearest of exchanger flue outlet . <, and metal heat exchanger put in place contrast to the ceramic heat exchanger. In the process of using metal heat exchanger, if this situation happens, you can consider the ceramic heat exchanger. Temperature difference is between 650 ℃ to 750 ℃. If the metal heat exchanger is placed in normal place where ceramic heat usually put;The service life comparison: since ceramic heat exchanger with high temperature resistance, this partly replace metal heat exchanger. What's more, energy-saving rate is also different. Metal heat exchanger can be placed in 700 ℃ or less;4 >, corrosion resistance, its application effect is very different. So the metal-heat-exchanger's heat-resistant temperature is high and the service life is the countless times of metal heat exchanger. The place with highest temperature does not need high temperature protection.

- Q: How do refractory materials apply into pyrophyllite?

- Generally speaking, shaped refractory materials require of some powdery materials like spray grouts and iron trough in addition to pyrophyllite brick made of a mixture of pyrophyllite aggregate and powers.

Send your message to us

High Purity Green Silicon Carbide - Low Price Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords