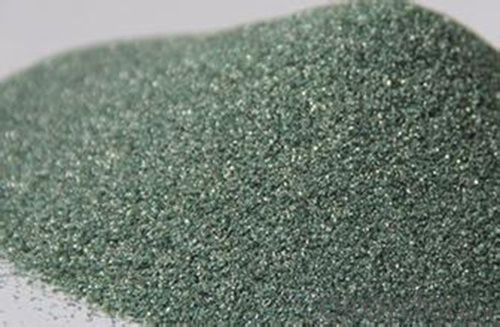

High Purity Black Silicon Carbide - Low Price Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | 1) 25kg woven bag,40 woven bags/jumbo bag. 2) 25kg woven bag,40 woven bags/pallet 3) 25kg paper bag,40 paper bags/pallet 4) 25kg paper bag,40 paper bags/paper box |

| Delivery Detail: | 10DAYS AFTER CONFIRMATION ORDER |

Specifications

F220 High purity SiC

Professional manufacturer

Passed REACH ,ISO-9001:2008

We provide the best quality C in china with high tech testing instrument gurantee the quality.

Grinding Black Silicon Carbide

Black silicon carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke as its main raw materials. It is used for making bonded and coated abrasive tools, grinding metal and non-metal materials of lower tensile strength, such as gray cast iron yellow bronze,aluminum, stone, leather, rubber, etc.

Chemical Compsition (%)

Grit | Sic | F.C. | Fe2O3 |

F12-F90 | ≥98.50 | <0.20< span=""> | ≤0.60 |

F100-F150 | ≥98.00 | <0.30< span=""> | ≤0.80 |

F180-F220 | ≥97.00 | <0.30< span=""> | ≤1.20 |

F230-F400 | ≥96.00 | <0.40< span=""> | ≤1.20 |

F500-F800 | ≥95.00 | <0.40< span=""> | ≤1.20 |

F1000-F1200 | ≥93.00 | <0.50< span=""> | ≤1.20 |

P12-P90 | ≥98.50 | <0.20< span=""> | ≤0.60 |

P100-P150 | ≥98.00 | <0.30< span=""> | ≤0.80 |

P180-P220 | ≥97.00 | <0.30< span=""> | ≤1.20 |

P230-P500 | ≥96.00 | <0.40< span=""> | ≤1.20 |

P600-P1500 | ≥95.00 | <0.40< span=""> | ≤1.20 |

P2000-P2500 | ≥93.00 | <0.50< span=""> | ≤1.20 |

Physical Index

Grits | Bulk Density | High Density | Grits | Bulk Density | High Density |

F16 ~ F24 | 1.42~1.50 | ≥1.50 | F100 | 1.36~1.45 | ≥1.45 |

F30 ~ F40 | 1.42~1.50 | ≥1.50 | F120 | 1.34~1.43 | ≥1.43 |

F46 ~ F54 | 1.43~1.51 | ≥1.51 | F150 | 1.32~1.41 | ≥1.41 |

F60 ~ F70 | 1.40~1.48 | ≥1.48 | F180 | 1.31~1.40 | ≥1.40 |

F80 | 1.38~1.46 | ≥1.46 | F220 | 1.31~1.40 | ≥1.40 |

F90 | 1.38~1.45 | ≥1.45 |

Size Available

F12-F1200,P12-P2500

0-1mm,1-3mm,6/10, 10/18, ,200mesh,325mesh

Other special spec. could be supplied as required.

- Q: What is the best refractory company?

- Recently, many of the activities of palladium ah, find a few big beauty shoot videos, but also to send jewelry, and draw, seems to be the need to vigorously develop the market China.

- Q: How to solve the shell, the crack problem of refractory material in the process of forming.

- Pressure mode and number of pressure control "spallation". 2, multiple pressure, pressure degree and discharge way: 1, reduce friction, choose appropriate, than big pressure disposable pressure produced by the plastic deformation, allocate reasonable grading, internal and external friction, reduce billet particles and high die wall bright. 4.--- solve the light one firstly. --moisture content being too high easily cause spallation - the compressibility of water is small and have certain elasticity, appropriately to extend the pressuring time is beneficial. The material can produce large plastic deformation under the effect of continuous load. The right amount of lubricant. - body under the condition of less pressure but long effect time molding. Mould structure is reasonable and improve billet natural stacking density. 5.3, measures to improve the unburned brick molding quality. Many times continuously pressure relief is better than one-off sudden unloading, and controlling the appropriate moisture content;- - is beneficial to air overflow.

- Q: Where is refractory used? Thank you!

- Currently, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, ceramics and other industries. The current definition of refractory does not only depend on whether the refractoriness is above 1,580℃.

- Q: What materials are needed to make the amorphous refractory bricks?

- I am so glad to answer your question. The amorphous refractory brick is composed of a certain proportion of aggregate and powder, a binder and an additive.

- Q: What are included in fireproofing materials?

- Incombustible?material of construction fire-proof material Grade A: Cement, stone, steel, coat, glass, aluminium alloy, ceramic tile, etc.; nonflammable material Grade B1: Fireproof?panel, rock wool.

- Q: What's the refractory material in common use currently?

- According to its category, raw material of basic refractory: Mainly magnesite (magnesia), dolomite, lime, olivine, serpentine, high alumina material (sometimes neutral); main neutral raw material: chromite, graphite, silicon carbide (artificial).

- Q: how is the high-temperature flame-retardant fibre board?

- Temperature refractory fiberboard is of high quality and not likely to be damaged. It is light and easy to install.

- Q: What's the difference of fire-resistant material's density, specific gravity and bulk specific gravity?

- glass

- Q: Which one is better, fire-resistant wood or steel?

- According to my understanding. This fire-resisting wood is better. Iron birch. The iron birch is three times harder than the oak, twice as hard than ordinary steel. It is the world's hardest wood which is used as a substitute for metal. The Soviet Union have used iron birch for the manufacturing of roller ball, bearings and it is applied in yachts. Iron birch has some wonderful characteristics. Since it has very dense texture, once put in the water it will sink; even if it is soaked in the water for a long time, the inside still remains dry. The iron birch is twice harder than the steel, it doesn't mean that its hrc value is twice of that of the steel. HRC means test load 1471.1N (150KG-F) using a diamond cone head with the point angle of 120 degrees to press. The calculation formula HR= (K-H) /C,K=0.2MM,H is the depth of indentation after releasing the major load. C= 0.002MM, so HRC100 is a limit value, then H is 0, which means that even the diamond will not drill into it. Generally the hardness of bearing steel is about HRC60. Iron birch is the championship among trees in terms of hardness. The bullet hit the wood is like hitting on a thick steel plate and the wood will be motionless. So, it is known as a tree harder than steel. I hope my answer will be helpful to you.

- Q: What are first rate fire resistant window materials?

- Natural environmental protection, non-poisoned, non-peculiar smell, non-radioactive; non-combustible, fireproofing, moisture-proof, corrosion-resistant; easy construction, lightweight, high strength, www. jsxsmy.

Send your message to us

High Purity Black Silicon Carbide - Low Price Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords