Graphite Electrode Industry Standard Dia.40-600mm or 1.6"-24" Graphite Electrodes

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

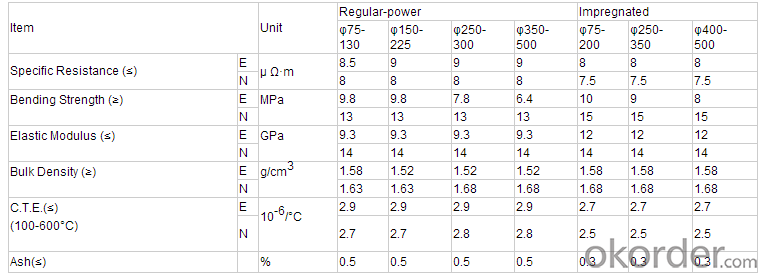

Graphite Electrodes Specifications

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What is the difference between pyridine type nitrogen and graphite type nitrogen?

- High purity graphite is said to produce graphite electrode, ash is very low, generally below 10 million.

- Q: Is graphite flammable?Why do I bake pencil cores with a fever that doesn't burn?

- The temperature is not enough, the composition of graphite is carbon, of course, flammable, but each kind of object burning point is not the same, the nature of graphite is relatively stable, burning point is very high, cigarette lighter this temperature is certainly not burning up.Useful words, remember to adopt Oh, thank you ~!

- Q: Electrolytic salt water why use iron as a cathode, all with graphite can not?

- The iron electrode is easier to be installed in the electrolytic cell, which is more convenient than the graphite electrode, and the density of the graphite is small. After being adsorbed by hydrogen, the graphite is easy to float up, and the density of the iron is larger. This problem does not exist in the.5

- Q: Graphite electrode in milling machine processing, dust is especially big, boot 5 minutes, workshop can not open the figure, what is the solution?

- This is to use the dust collector, the graphite itself is a semiconductor, can not be electrostatic dust removal

- Q: Specification for graphite electrodes commonly used in steel works

- General specification for graphite electrode diameter Phi 300 Phi 500mm, Phi Phi 550 - the current usage of 800mm graphite electrodes is also great, the graphite electrode length was between 1600 and 2700mm.

- Q: Is the anode of electrolytic water suitable for ordinary titanium wires?

- The graphite is cheaper and easier to obtain, but the carbon electrodes sold in the general market are not very pure at most times. The experiment is done for a period of time, and the carbon is inexplicably broken, especially if you need to work for a long time. So, if your graphite electrode is of good quality, it's still graphite.

- Q: National standard for graphite electrodes

- Page 7 the international standard specifies the shape, dimensions and tolerances, technical requirements, test methods, packaging, marking, storage, transportation and quality certificates of graphite electrodes. This standard applies to high quality petroleum coke, asphalt, coke as the main raw material, through molding, roasting, impregnation, graphitization and mechanical processing made of, power supply arc furnace as conductive material of ordinary power graphite electrode. Common power graphite electrode GB

- Q: The production of one ton of steel required graphite electrode

- The consumption of graphite electrode in steelmaking in arc furnace, according to the different material, different specifications of graphite electrode used (normal power graphite electrode, high power graphite electrode, ultra high power graphite electrode) have relations.

- Q: Why is the production of one ton of ultra high power graphite electrode requires 1.05 tons of coke?

- After calcined to eliminate ash and volatile part of the points in this process will be a lot of weight loss, in the process of crushing mixing in process of baking or graphite in high temperature heat treatment, another part of the impurities were excluded, so the raw material is higher than the rate of finished products.

- Q: 800KVA and 12500 EAF transformer data graphite electrode furnace.

- The graphite electrode must be roasted by a cathode or anode baking furnace, and a large amount of harmful gas and dust will be produced during the roasting process.

Send your message to us

Graphite Electrode Industry Standard Dia.40-600mm or 1.6"-24" Graphite Electrodes

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords