Graphite Electrode Applications - Graphite Electrode with Nipple Price-HZ -400M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode.

The range of diameters covers from 200mm to 700mm.

Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

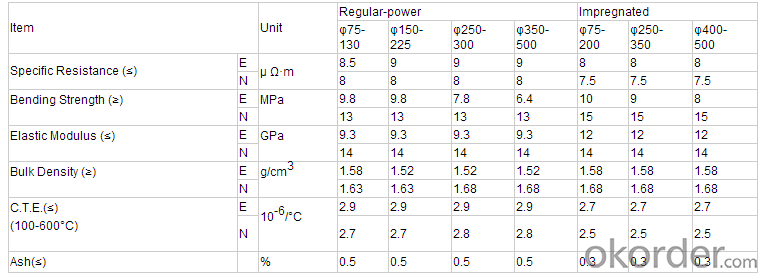

Graphite Electrodes Specifications

Do you know our material of the graphite electrode?

The regular power graphite electrode is made from petroleum coke with a little pitch, which meets

the state standards YB/T4088-2000

The high power graphite electrode is made form 70% petroleum coke and 30% imported needle

coke, which meets the state standards YB/T4089-2000

The ultra high power graphite electrode is made form 100% imported needle coke, which meets

the state standards YB/T 4090-200

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Classification, uses and manufacturers of graphite electrodes

- The difference between graphite electrodesMainly from the current, density, resistance, bending strength, ash parameters are measured

- Q: Why use platinum ferroalloy instead of iron as electrode?

- Silica (Silica) is widely used in paint, ink, plastic, rubber and cosmetics, are often added to increase the performance of silica, such as oil absorption, extinction, strengthen the mechanical... Etc., and can reduce the cost of...

- Q: What is the difference between pyridine type nitrogen and graphite type nitrogen?

- The fine structure graphite is the raw material used in the production of graphite electrode. The particle size is relatively small, generally below 0.5.

- Q: Is the anode of electrolytic water suitable for ordinary titanium wires?

- Graphite firstFirst of all, the titanium electrode is usually not pure titanium, it should be titanium with a metal oxide coating. Secondly, the advantages of the titanium electrode is mainly to save electricity, the corrosion resistance of carbon is much stronger than that of industrial production, if the meaning is relatively large, but it is still in laboratory experiments, electrolysis of water, not what meaning.

- Q: MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- The impact of carbon on the car is quite large, first of all, to reduce the power of the engine, that is, to make the power output uneven and gradually attenuated, in other words, more and more lack of force. Two is to increase fuel consumption, increase your financial burden.

- Q: How does graphite produce solar cells?

- The team at the Massachusetts Institute of Technology has confirmed that electrodes based on graphene and ITO devices are comparable in efficiency. Although the power conversion efficiency of graphene is 4.2% lower than that of a general silicon cell, it will be competitive for special use in the future.

- Q: What are the factors that affect the electrode wear rate of machine tools?

- Effect of peak pulse current on electrode wear. The peak current has a great influence on electrode wear, but the curves are very different due to the different materials of the electrode and the workpiece. In the copper electrode machining steel, general peak current, electrode loss is also large, but also have a great relationship with the pulse width, so in practice, we should choose different peak current of different area according to the data processing technology of power supply and discharge pulse width, can make the processing speed is high, and the electrode loss small.

- Q: What kinds of carbon are there?

- The carbon block can be divided into blast furnace carbon block, aluminum carbon block and electric furnace block. Carbon products can be divided into carbon products, graphite products, carbon fibers and graphite fibers according to the depth of processing. Carbon products can be divided into graphite products, carbon products, carbon fibers and special graphite products according to the raw materials and the production process. Carbon products according to their ash content, and can be divided into multi gray products and less ash products (including ash below l%).

- Q: Electrolysis of CuCl2 solutions with graphite electrodes

- After energization, electrolysis occurs, not ionizationIonization does not require energization, and can occur in aqueous or molten state.

- Q: What are pyrolytic graphite electrodes used for?

- In 1960s, copper is widely used as electrode material, usage rate of about 90%, about graphite only 10%; in twenty-first Century, more and more users start using graphite as the electrode material, in Europe, more than 90% above the graphite electrode material is. Copper, the once dominant electrode material, has almost lost its advantages over graphite electrodes.

Send your message to us

Graphite Electrode Applications - Graphite Electrode with Nipple Price-HZ -400M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords