GPC with lower Sulphur0.03% max in 1-3mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

GPC has good characteristics with low ash, low resistivity, low sulphur, high carbon and high density. It is the best material for high quality carbon products. It is used as carbon additive in steel industry or fuel.

Features:

1.Our strong team provide you reliable service that make you feel purchasing is more easier

2. We ensure that we can supply capability with competitive price.

3. Work strictly to guarantee product quality,

4. Highest standard of integrity. Guarantee customer's benefit.

5. Supplying Pet Coke, Met coke, Foundry Coke, Carbon Raiser etc.

Specifications:

F.C.% | 95MIN | 94MIN | 93MIN | 92MIN | 90MIN | 85MIN | 84MIN |

ASH % | 4MAX | 5MAX | 6 MAX | 6.5MAX | 8.5MAX | 12MAX | 13MAX |

V.M.% | 1 MAX | 1MAX | 1.0MAX | 1.5MAX | 1.5MAX | 3 MAX | 3 MAX |

SULFUR % | 0.3MAX | 0.3MAX | 0.3MAX | 0.35MAX | 0.35MAX | 0.5MAX | 0.5MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 0.5MAX | 0.5MAX | 0.5MAX | 1MAX | 1MAX |

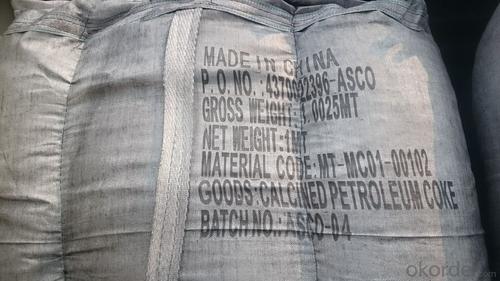

Pictures

FAQ:

1. Your specification is not very suitable for us.

Please offer us specific indicators by TM or email. We will give you feedback as soon as possible.

2. When can I get the price?

We usually quote within 24 hours after getting your detailed requirements, like size, quantity etc. .

If it is an urgent order, you can call us directly.

3. Do you provide samples?

Yes, samples are available for you to check our quality.

Samples delivery time will be about 3-10 days.

4. What about the lead time for mass product?

The lead time is based on the quantity, about 7-15 days. For graphite product, apply Dual-use items license need about 15-20 working days.

5. What is your terms of delivery?

We accept FOB, CFR, CIF, EXW, etc. You can choose the most convenient way for you. Besides that,

we can also shipping by Air and Express.

6. Product packaging?

We are packed in bulk ship or in ton bag or placing in container or according to your requirements.

7. Notice

please note that the price on Alibaba is a rough price. The actual price will depends on raw materials, exchange rate wage and your order quantity .Hope to cooperation with you, thanks !

- Q: How does carbon contribute to the hardness of steel?

- Carbon contributes to the hardness of steel through a process known as carbonization. When carbon atoms are introduced into the iron lattice of steel, they create interstitial solid solutions, causing the lattice to become distorted. This distortion prevents the iron atoms from sliding past each other easily, thereby increasing the resistance to deformation and making the steel harder. Increasing the carbon content in steel increases the strength and hardness, up to a certain limit. However, excessive carbon can also make the steel brittle, so it is important to find the right balance to achieve optimal hardness without compromising other properties of the steel.

- Q: RT~ I remember our teacher said, but I forgot all of a sudden......Ask for advice!

- Addition is in organic matter. Ester and carboxylic groups in C=O can not add, and aldehyde and ketone groups in addition to C=O, plus open a key in a C=O, into alcohol.

- Q: How are carbon fibers produced?

- Carbon fibers are produced through a multi-step process known as carbonization, where a polymer precursor material, usually made from polyacrylonitrile (PAN) or pitch, is heated and chemically treated to remove non-carbon elements. The resulting material is then subjected to high temperatures in an oxygen-free environment, transforming it into a carbon-rich fiber. This process creates strong, lightweight carbon fibers with excellent mechanical properties, making them ideal for various industrial applications.

- Q: How are carbon nanomaterials used in electronics?

- Due to their unique properties and versatility, carbon nanomaterials find widespread use in the field of electronics. A common application of these materials is in the creation of highly efficient and flexible conductive materials. Both carbon nanotubes (CNTs) and graphene, which fall under the category of carbon nanomaterials, possess remarkable electrical conductivity, making them ideal for the production of conductive components in electronic devices. CNTs are cylindrical structures comprised of rolled-up graphene sheets. They can be utilized as interconnects in integrated circuits, enhancing performance by reducing resistance and promoting heat dissipation. Furthermore, CNTs can be employed in transistors, facilitating faster and more efficient switching due to their high electron mobility. Their small size and flexibility render them suitable for the construction of transparent conductive films used in touchscreens and flexible electronics. On the other hand, graphene is a two-dimensional sheet composed of carbon atoms arranged in a hexagonal lattice. It is renowned for its exceptional electrical conductivity, high electron mobility, and excellent thermal conductivity. Materials based on graphene can function as electrodes in batteries and supercapacitors, thereby enhancing their energy storage capacity. Additionally, graphene transistors possess the potential to replace traditional silicon-based transistors, resulting in faster and more energy-efficient electronic devices. Furthermore, carbon nanomaterials, particularly CNTs, exhibit promise in the realm of nanoelectromechanical systems (NEMS). NEMS devices are exceedingly small and sensitive, enabling applications such as sensors, actuators, and resonators. CNT-based NEMS devices have displayed exceptional sensitivity and responsiveness, making them suitable for various sensing applications, including pressure, gas, and biological sensing. In conclusion, carbon nanomaterials play a vital role in the field of electronics by offering highly conductive and versatile materials for different components and applications. Their unique properties, such as excellent electrical and thermal conductivity, make them ideal for the production of faster, more efficient, and flexible electronic devices. As research and development in this field continue to advance, carbon nanomaterials are poised to revolutionize the electronics industry.

- Q: How are fossil fuels formed from carbon?

- Carbon undergoes a natural process that spans millions of years, resulting in the formation of fossil fuels. This process commences with the remnants of plants and animals that existed millions of years ago. These remnants, containing carbon, become buried beneath layers of sediment in bodies of water such as oceans and swamps. Over time, the pressure exerted by the sediment layers and the heat emanating from the Earth's crust lead to the occurrence of diagenesis. During diagenesis, the organic matter within the remnants undergoes chemical alterations, turning it into a substance called kerogen. As additional sediment layers continue to accumulate, the temperature and pressure intensify. Eventually, the kerogen experiences catagenesis, wherein it is subjected to even higher temperatures. This causes the kerogen to disintegrate and convert into liquid and gaseous hydrocarbons, which constitute the primary constituents of fossil fuels. Crude oil or petroleum arises from the formation of liquid hydrocarbons, while natural gas arises from the formation of gaseous hydrocarbons. Both of these fossil fuels can be extracted from the Earth's crust through the process of drilling. In brief, fossil fuels are generated from carbon through a intricate and protracted process that encompasses the burial, pressure, and heat treatment of organic matter across millions of years. This process alters the remains rich in carbon into hydrocarbons, which subsequently become the valuable resources we employ as fossil fuels today.

- Q: What are the consequences of increased carbon emissions on indigenous communities?

- Increased carbon emissions have significant consequences on indigenous communities. Firstly, these communities often rely on the land and natural resources for their livelihoods, so environmental degradation caused by carbon emissions can directly impact their ability to hunt, fish, and gather food. Additionally, climate change resulting from carbon emissions leads to more frequent and intense natural disasters, such as hurricanes and droughts, which can destroy homes and infrastructure in indigenous communities. Moreover, the loss of traditional knowledge and cultural practices associated with the changing environment can have profound social and psychological impacts on indigenous peoples. Overall, increased carbon emissions exacerbate existing inequalities and vulnerabilities faced by indigenous communities, threatening their way of life, well-being, and resilience.

- Q: How does carbon impact the formation and intensity of hurricanes?

- Carbon dioxide (CO2) and other greenhouse gases contribute to the warming of the Earth's atmosphere, leading to global climate change. This increased warming affects the formation and intensity of hurricanes. Warmer ocean temperatures provide more energy for hurricanes to form and strengthen, making them more intense. Additionally, higher levels of atmospheric moisture due to increased evaporation from warmer oceans also contribute to the formation and intensity of hurricanes. Therefore, carbon emissions play a significant role in the impact of hurricanes by fueling their formation and increasing their destructive potential.

- Q: What does "2T-250,1U-200@300" and "1Y-100" mean in carbon fiber cloth reinforcement?

- the indicates that the U type hoop is 200 wide and the spacing is 300; the 1Y-100 represents the width of the 100 width and each of the two sides of the beam. The units are mm.

- Q: How does carbon impact the quality of freshwater systems?

- Carbon can impact the quality of freshwater systems in various ways. Carbon dioxide (CO2) dissolved in water can lower its pH, leading to increased acidity and potentially harming aquatic organisms. Additionally, excessive carbon inputs from human activities like the burning of fossil fuels can contribute to eutrophication, causing algal blooms and depleting oxygen levels in water bodies, further compromising the health of freshwater ecosystems.

- Q: What are the different types of carbon-based composites?

- There are several different types of carbon-based composites, each with unique properties and applications. Some of the most common types include carbon fiber reinforced polymers (CFRPs), carbon nanotube composites, and carbon fiber reinforced ceramics. Carbon fiber reinforced polymers (CFRPs) are perhaps the most well-known and widely used carbon-based composites. They consist of carbon fibers embedded in a polymer matrix, such as epoxy resin. CFRPs are lightweight, yet incredibly strong and stiff, making them ideal for applications where weight reduction and high strength are crucial, such as aerospace, automotive, and sporting goods industries. Carbon nanotube composites are another type of carbon-based composite that have gained significant attention in recent years. Carbon nanotubes are cylindrical structures made of carbon atoms arranged in a hexagonal lattice. When incorporated into a composite material, they enhance its mechanical, thermal, and electrical properties. Carbon nanotube composites have potential applications in fields such as electronics, energy storage, and structural materials. Carbon fiber reinforced ceramics combine the high strength and stiffness of carbon fibers with the exceptional high-temperature resistance of ceramics. These composites are commonly used in industries that require materials capable of withstanding extreme temperatures, such as aerospace, defense, and nuclear sectors. Carbon fiber reinforced ceramics offer an excellent balance between strength, thermal stability, and low weight. Other types of carbon-based composites include carbon fiber reinforced metals, where carbon fibers are embedded in a metal matrix, and graphene composites, which incorporate graphene sheets into a polymer or metal matrix. These composites offer unique properties such as high electrical conductivity, thermal stability, and mechanical strength, opening up possibilities for applications in areas like electronics, energy storage, and structural materials. Overall, carbon-based composites offer a diverse range of properties and applications, making them invaluable materials in various industries that require lightweight, strong, and durable materials.

Send your message to us

GPC with lower Sulphur0.03% max in 1-3mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches