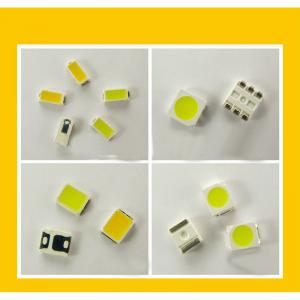

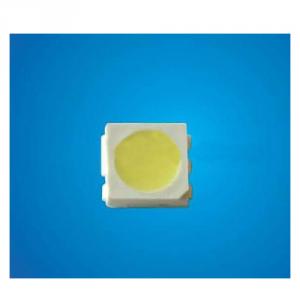

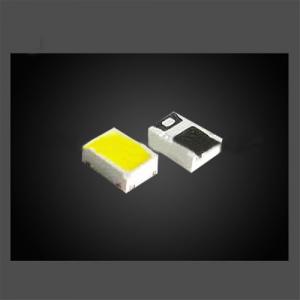

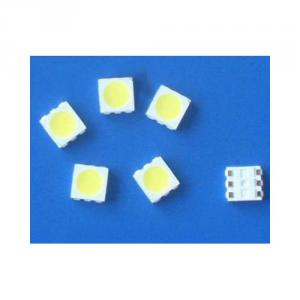

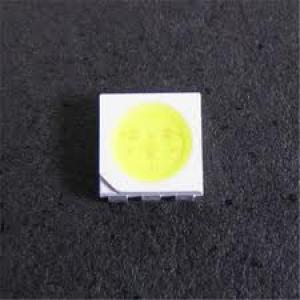

Good Quality Super Bright 5050 SMD LED From China Manufacturer

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications for LED Diode:

1.Electrical optical charactertistics(Ta25°C)

Parameter | Symbol | Min | Type | Max | Unt | Test Condition |

Luminous Intensity | IV | 6000 |

| 7000 | mcd | IF=20mA |

Correlated Color Temperature | CCT | 6000 |

| 6500 | K | IF=20mA |

Dominant Wavelength | ld |

|

|

| nm | IF=20mA |

Viewing angle | 2θ1/2 |

| 120 |

| deg | IF=20mA |

Forward Voltage | Vf | 3.1 |

| 3.2 | V | IF=20mA |

Reverse Current | IR |

|

| 5 | uA | VR=5V |

Suggestion Forward Current | IF | 3 | 5-10 | 20 | mA | IF=20mA |

2.Absolute Maximum Ratings (Ta=25°C):

Parameter | Rating | Unit | ||

Reverse Voltage | 5 | V | ||

Power Dissipation,Per Dice | 60 | mW/chip | ||

Operating Temperature Ranger | -25~+85 | °C | ||

Storage Humidity | 45%~85% | °F | ||

Storage Temperature Ranger | -30~+85 | °C | ||

Soldering Temperature |

|

| 260°C for 5 seconds | |

Peak IF(ma) (1/10Duty Cycle 0.1ms Pulse Width) | 60 | mA/chip | ||

Continuous Forward Current | 30 | mA/chip | ||

Features

Good quality super bright 5050 smd led

Suitable for all SMT assembly and solder.

RoHS compliant .

Super-luminosity chip LED.

Application

Our LED diodes are suitable for lighting products.

Optical indicator

Indoor display

Interior automotive lighting

Backlight for LCD, switch and Symbol, display

Light tube application

About Us

Established in 1999, we are one of the professional manufacturers specialized in LED products including LED diodes, LED digital display, LED ball bulb, LED spotlight, LED tube, LED panel light.

Our Service

Free sample after you give me your express account. Provide the best service to you!

- Q: 0603,0805,1206,3020,3528,5050,355 what is the current and voltage of these patch LED? Please give advice!

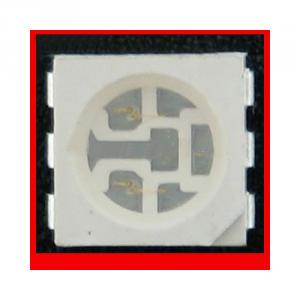

- SMD LED specification:(1) metal stent type: 0402, 0603, 0805, 1206, 3mm, 5mm, 6mm, 8mm, 10mm and so on.(2) metal support (commonly known as small butterfly) type: 2mm, 3mm and so on.(3) TOP LED (white shell) type: 1208 (30*20), 1311 (35*28), 1312 (35*32), 2220 (55*50) and so on(4) side light LED:0905 (22*12), 1105 (28*12) 1605 (40*14) and so on.

- Q: How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- Installed indoors, you can directly tear off the stickers on the 3M double-sided adhesive surface, and then fix the light bar where it needs to be installed. Just press it with your hands.

- Q: Patch LED light does not flash, why?

- Are you saying that lamp is flashing? You can check the power output, according to your standard parameters and SMD beads, lamp panel series parallel mode, calculate the power output to output power of the test, you may be wrong, power, overload, but also the effective part of you may be the circuit for power transmission is not stable or low

- Q: Patch LED market conditions

- Patch LED (SMD LED) is mainly used in lighting systems, decoration, electronic equipment, indicators, backlight, monitors and instruments and other fields. The decline in handset and LCD TV production in 2009 could affect the supply expectations for such components.

- Q: Does anyone know what the current rating of a white high brightness LED patch is? Where can I find out?

- LED high power and low power, small white rated current and LED wafer, such as a chip is 20MA two 40MA.... High power 0.5W, 100-150MA, 1W, 350MA current rating in the relevant product specifications

- Q: What are the storage requirements of SMT patch LED (LED)?

- Moisture-proof packing- anti SMD LED in the transport and storage of moisture absorption, SMD LED shall be placed in sealed moisture-proof bag, inside put damp proof agent for protection, and placed the humidity humidity SMD display card packaging bag.

- Q: What is patch LED?

- Patch LED refers to surface mount LED.The LED is separated from the PCB board in the form of inline and surface mount. Piranha, 3mm lights, and 5mm lights are all pins. While most high-power LED is surface mount, that is, patches. Small power LED also has the form of surface mount such as PLCC-2 and PLCC-4.

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- No difference, because the core of the two is the same, are diode PN junction, but no packaging, the production process is a little different

- Q: Notes on patch LED

- Clean, do not use an unknown chemical liquid to clean the patch LED: an unknown chemical liquid may damage the patch LED. When necessary, immerse the patch LED in alcohol, less than 1 minutes at normal room temperature, and dry naturally for 15 minutes before starting to use

- Q: The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- The ten patch LED lamps are connected in parallel with rated power of 5 watts and voltage 3.3V.

Send your message to us

Good Quality Super Bright 5050 SMD LED From China Manufacturer

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords