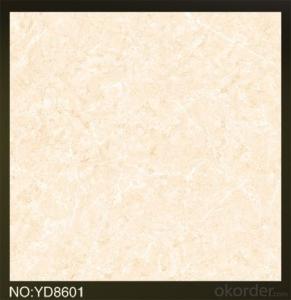

Glazed Porcelain Floor Tile 600x600mm CMAX-TC6021P

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Information:

Tile Type | Glazed Porcelain Tile, floor tiles |

Certificate | ISO13006, ISO9001 |

Finish | Matte Finish, Lapato Finish, Rough Finish |

Size | 60x60 mm |

Selection Range | Several Colors available |

Features:

1) Unique natural sandstone image designs and exclusive quality;

2) Used for indoor & outdoor wall and floor decorations, as well as Stair Case Product;

3) Easy to install, anti-dust, washable, acid-proof, alkali-proof, durable

4) Material: porcelain

5) Basic size: 600x600x9.8mm, 100x600mm, 150x600mm, 300x300mm, 300x600mm available based on clients’ requirements;

6) Available dimensions

Material | Porcelain |

Dimension | 600x600x9.8 mm |

Packing | Carton + Wooden Pallets |

Finish | Glossy, over 90 degree. |

Usage | Floor and wall |

The glazed porcelain tile is widely used for interior house flooring, hotel lobby flooring, exclusive brand showroom, clubs villas as well as other public sites.

We could go with OEM model, making 2nd production based on client’s requirement;

We could offer flexible service on shipment and better support on payment term;

Our quality guarantee is based on the strict production procedure, quality controlling on the shade, straightness as well as 2nd production and final package.

Specification and technical parameter:

· Matte Finish, Lapato Finish, Rough Finish

· Water absorption:<0.1%< span="">

· Anti-Resistance: R10

· Delivery Time: within 15~20 days after order confirmation.

· Package standard: 4pcs/carton, 40 Cartons/pallet, 32 Kgs/Carton.

- Q: i need to cut a hole in ceramic floor tile. i have tried many things such as dremel with different ceramic tile cutting attachments and a carbide hole saw.what should i try next?

- In the plumbing section of most hardware stores a cable saw can be found its used to cut pipe in hard to reach areas. some will cut tile. In the drill bit area find a Glass/ Tile bit big enough for the cable and go to it. a coping saw may work other thought. use tile bit to start and nippers, files will work as well use water as a lube. I hope someone else has a better Idea for you.

- Q: Moved into a house where prior owner used glazed porcelain tile. Job unfinished but a little tile left behind. Not enough! Can anyone help me find GEO CERAMICHE Natura Sable BL 12x12 (or larger, I can cut it down). Have looked online to no avail (yet). Neighbors tell me the tile was bought at least 4 years ago but not later. Can anyone help me find 5 pieces of this tile?

- Find where the tile was bought 1st.. Many big box stores will private label name brand tiles ( and many products) so you can t cross shop them..After 4 years I won t give you much of a chance to find them ..sorry... Styles change along w/ technology and they switch things to change w/ the times.It may be still available but chances are slim..Is it in a place that some sort of mosaic can be used as a decoration? Or maybe a good rug? Start w/ the big box stores but don t waste to much gas chances are slim .. I wish you luck ..

- Q: What‘s the average cost to install tile baseboards? I‘m replacing my wooden baseboards with tile and was just wondering what an average price to just do the baseboards with tile. I have roughly 1500 inches of floorboard that is going to be done and I am looking to use 20 X 20 inch tile. No bullnoseing or anything special, just cut the tile and install.Thanks

- Michael G makes a good point. If it was me, the price would be more like $750+, because I'd have to cut the tile, and do layout, apply it, then grout it. the top edge grout is a real pain, and poses the biggest challenge to get it right. Most customers always seem to find fault in that one issue. Of course, If I was doing the whole job instead of just the base tile, that price would be more reasonable, being factored in with the overall job. a Comment to the other poster: A lot of people prefer tile base to wood/paper (most base is hard paper nowadays), simply because of water or liquid spills that can affect drywall and baseboards. by using a tile base, this makes the wall less likely to suffer as much damage as could occur without it in place. Besides, most tile bases compliment the tile floor job, and colors. Likewise, I get a lot of callbacks because customers, after looking at tile base for a while, want me to come back in and set tiles up the wall, which means less wall maintenance issues, no need to paint, mold is less likely to form and become an issue, and people sitting in a chair with the heads against the wall is less likely to smudge it, as well as kid issues with markers and crayons.

- Q: We have a big problem with our tiles in our bathroom, they wont stick.We have painted the floor with the pva. used (waterproof athesive) don‘t know if thats the correct name for it. my boyfriend has let his dad do the tiling as he knows how to do it. i told him to get a profesionals. but he wants he‘s dad. so now we have been having this problem. if any one knows what should we do or use different glue or something, that would really help., thanx

- First off, PVA glue is a BIG NO NO! it is a craft glue and should never be used for installing any kind of tile unless its in a doll house! The glue will not stick to the tiles and will come up soon after you walk on them!!! Stick your finger in that glue and wait for it to dry, You will be able to peel it off and almost have the same shape of your finger! Pretty cool but not good for tile installation! What kind of tiles are they? Ceramic or stone? You should be using thinset to install the tile! VCT tile? you should be using VCT contact cement/glue! Remove the tiles, Peel any Glue off the tile and floor (should be very easy to do) and use the proper adhesive for the tile you have!

- Q: The tile at the store says $5.00 per square foot.. so I'm assuming that's the cost of the tile only.. and then how much does it generally cost to install? Another $5 or more per square foot? I am new to this all.

- Yes that is a sq ft price. Installation prices vary from area to area. Normaly, you can call an installer and they will give a free in home estimate although some do charge for this. I live in the southern US. Here the normal price for installation is about $3.00 to $5.00 per sq ft on a ready site. Prep work (ie current flooring removal, furnature moveing, etc) is extra.

- Q: I have never laid tiles before and I would like to work from the ceiling down. In the shower I am going to use thin set. the rest of the bathroom is green board. which I intended to use a tile adhesive.the reason I wanted to go from ceiling down is I think the layout will look better

- measure the wall height and measure the tile. Split the difference so that you don't have a sliver of tile at the end of you installation. Take a level and draw a line in the center of the wall as a divider for tile layout. Make sure again you have at least a good amount of a tile at the bottom and the top. You can start from that line using tile adhesive. Don'r glob it on use an 1/8th inch tooth trowel. You dont need thin set except for a floor. BTW the best rock to use in this area is purple board. It resists mold. Good Luck

- Q: I‘m looking to re-tile my kitchen... I would like to get good quality tile, at a good price. Can I trust tile purchased at any particular large hardware chain, or should I seek out a specialty flooring store? Or does it even matter that much - is tile just tile?

- Go to Home Depot, you will be able to find someone that works there and they will show you a wide variety of ceramic tiles. You would probably find what you are looking for or either you would see something you like. Let the professionals handle the work.

- Q: I have extra floor tiles that i had my kids paint and i want to put them together for my husband for fathers day. any ideas on how to do that?

- well you can put the tiles somewhere else? Maybe buy some more and make a cool tile medallion in your backyard or something? That seems to be pretty popular !

- Q: A 15 foot by 18 foot porch floor is to be completely coverede with 1-foot square tiles. White tiles are to cover the center of the floor and green tiles are to form a 2-foot wide border around the white tiles. How many green tiles and how many white tiles will be needed?/. help plz. can you show work thanks very much.

- Draw a picture and use practical thinking plus arithmetic. Then just add up the area of the sections of tile.

- Q: There are thousands of individual tiles. If one falls off or something like that does everything burn up? thanks and how did the heat shield not work for the shuttle in 2003? it might have been in 2001 i have to ask my science teacher

- The Columbia disaster happened because during launch some insulation came off the external tank and hit the leading edge of the wing, right between the two tiles and damaged the seal. During the re-entry, the hot gases from the re-entry friction got behind the tile and melted the wing structure. A few tiles fall off during flight, but it is not a big problem, less so than during the early years of shuttle operations. If you look at the shuttles, some tiles appear fresher then others.

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-TC6021P

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches