Glass Wool Reinforced Ceramic Fiber High Temperature Paper

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

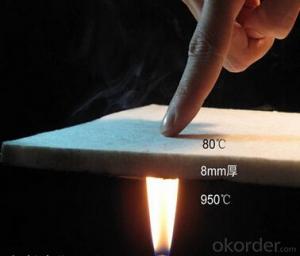

Ceramic fiber high temperature paper

JIUQIANG ceramic fiber high temperature paper is manufactured from high-grade ceramic fiber with low slag ball content, and formed into excellent flexible sheet through unique beating, deslagging, slurry-compounding, long net forming, vacuum water removal, drying, cutting and rolling processes.

It is featured with high temperature resistance and heat insulation and high anti-melt capability, very low thermal conductivity, chemical corrosion resistance and thermal shock stability.

So the paper can be widely used in building, glass industry for teeming pads separation. It provides maximum heat resistance and thermal insulation in limited space.

Features of High Temperature Paper

1.Uniform thickness and smooth appearance;

2.Contains no asbestos and anticorrosion; No action with aluminum fluid;

3.Low heat storage;

4.Low thermal conductivity;

5.Good flexibility and toughness and resistance to avulsion;

6.Excellent chemical stability;

7.Excellent machining property;

8.Excellent electric insulation and sound insulation;

9.Excellent thermal shock resistance

Typical Application of High Temperature Paper

1.Appliance heat seals

2.Parting plane in refractory linings

3.Combustion chamber liners

4.Backup lining for metal troughs

5.Hot top linings

6.Thermal and electrical insulation

7.Refractory backup insulation

8.Coke oven door shook absorption medium

9.Kiln car deck covering

Technical Data of High Temperature Paper

Grade | Standard | High Pure | High Aluminium | Zirconium | |||

Max. Temperature (°C) | 1050 | 1150 | 1260 | 1430 | |||

Shrinkage on Heating (%) | 800°C×24h≤-3 | 1000°C×24h≤-3 | 1280°C×24h≤-3 | 1400°C×24h≤-3 | |||

Organic Content (%) | ≤5 | ≤5 | ≤5 | ≤5 | |||

Thermal conductivity by mean temp. (W/m.k.) (250kg/m3) | 200°C | 0.055~0.065 | 0.060~0.070 | ||||

400°C | 0.110~0.120 | 0.105~0.125 | |||||

600°C | 0.160~0.170 | 0.170~0.180 | |||||

Chemical Composition (%) | AL2O3 | 43 | 47 | 55 | 38 | ||

SiO2 | 53 | 51 | 44 | 44 | |||

Fe2O3 + Ti2O3 | ≤1.2 | ≤0.3 | ≤0.3 | ≤0.2 | |||

CaO + MgO | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.2 | |||

NaO + KO2 | ≤0.5 | ≤0.3 | ≤0.3 | ≤0.2 | |||

Density (kg/m3) | 170~230 | ||||||

Size (mm) | Length: 60000/40000/30000/20000/15000/12000 Width: 1220/610 Thickness: 1~6 (Other sizes and shapes on request. ) | ||||||

Package |

Carton box | ||||||

Certificates |

ISO9001-2000; ISO14001-2000 | ||||||

Remarks: The data above is for reference. The Max. temp. depends on the working conditions.

- Q: Which one among polystyrene?boards, rock wool boards and glass?wool?boards is the best materials for external wall thermal insulation?

- Polystyrene?boards are better in terms of external wall thermal insulation materials but now polystyrene?boards are not allowed to use. Rock wool and glass wool can be used, but they need good waterproofing treatments.

- Q: Rock wool board and glass?wool?board, which is more harmful to human body?

- Rock wool board, rock wool board has more layers!

- Q: What are the requirements for filling the glass wool insulation materials?

- It depends on design requirements, local climate and budget.

- Q: Is the microporous aluminum silicate coated with aluminum wool?

- Aluminum silicate is white fiber

- Q: To reach better sound absorption effect, which should be filled in the keel, glass wool felt / board or polyester fiber cotton felt / board ?

- Glass wool board Glass wool board is mainly used for sound insulation. Glass wool felt is mainly used for thermal insulation, and polyester fiber cotton felt is mainly for thermal insulation and sound absorption.

- Q: how to choose external wall insulation materials for glass wool?

- Extrusion plate: Better physical property, small heat-transfer coefficient, low cost, suitable for buildings that requires not much exterior decoration; phenolic foam board: it can reach A level fireproof, low heat transfer coefficient, high cost. it becomes powders after hand pinching. It has poor adhesion; modified polyurethane board: It can reach A level fireproofing, low heat transfer coefficient, high cost. It can be used with various decorative materials.

- Q: What are the differences among glass wool, rock wool and mineral wool?

- Glass wool is usually used in the industrial field, that is glass?silk. Rock wool is generally used in external thermal insulation of pipelines, and in the sound insulation of partitions or the thermal insulation of ceilings. You must know about mineral?wool?boards, generally, they are used in office as suspended ceilings. The main function of which is sound absorption. If you want thermal insulation and sound absorption, you can use them both, haha.

- Q: What is the density of glass wool?

- Glass wool, a man-made inorganic fiber, belongs to a kind of glass fiber. It is a spongiform material made through fibration of melten glass. It is an inorganic fiber whose chemical components belong to glass, having good formability, low bulk density, low thermal conductivity, good thermal insulation and sound absorption, corrosion resistance and chemical stability. For centrifugal glass wool whose thickness exceed 5 cm and unit weight is 16Kg / m3, the sound absorption coefficient of low frequency125Hz is about 0.2, and that of middle and high frequency is close to 1. When the thickness continues to increase from 5cm, the low-frequency sound absorption coefficient also increase gradually. When the thickness is greater than 1m or more, 125Hz low frequency sound absorption coefficient will also be close to 1. Thicknesses of acoustic glass wools often used in architectural acoustics are 2.5cm, 5cm, 10cm, and unit weights are16,24,32,48,80,96,112kg / m3. centrifugal glass wool whose thickness is 5 cm and unit weight is 12-48kg / m3 is usually used.

- Q: The differences between rock wool board and glass?wool?board

- good explanation

- Q: What is the main use of glass wool insulation materials?

- Uses of glass wool insulation material, glass wool: The main raw materials are glass, class A fireproof rating, thermal conductivity coefficient 0.037, shrinking temperature of 270 degrees, use: Good cold insualtion property.

Send your message to us

Glass Wool Reinforced Ceramic Fiber High Temperature Paper

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords