Silica Brick for Glass Furnace Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.high temp Refractoriness Under Load

2.good stability under high temp

3.low pollution

4.Refractory Silica Brick

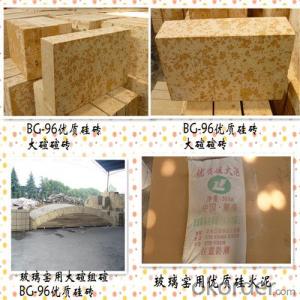

Silica Bricks for Glass Furnace

,there are series silica bricks for glass furnace, BG-95, BG-96A, BG-96B. high purity silica for brick mading, with science material proporation and technic of products. different calcined machine, automation, short cycle of production.

Item | BG-94 | BG-95 | BG-96A | BG-96B | |

Chemical composition | SiO2 | ≥94 | ≥95 | ≥96 | ≥96 |

Fe2O3 | ≤1.5 | ≤1.5 | ≤0.8 | ≤0.7 | |

Al2O3+TiO2+R2O |

| ≤1.0 | ≤0.5 | ≤0.7 | |

Refractoriness °C | 1710 | 1710 | 1710 | 1710 | |

Apparent Porosity% | ≤22 | ≤21 | ≤22 | ≤22 | |

Bulk Density g/cm3 | ≥1.8 | ≥1.8 | ≥1.8 | ≥1.8 | |

True Density,g/cm3 | ≤2.38 | ≤2.38 | ≤2.34 | ≤2.34 | |

Cold Crushing Strength Mpa | ≥24.5 | ≥29.4 | ≥35 | ≥35 | |

0.2Mpa Refractoriness Under Load T0.6 °C | ≥1630 | ≥1650 | ≥1680 | ≥1680 | |

Permanent Linear Change On Reheating(%)1500°CX2h | 0~+0.3 | 0~+0.3 | 0~+0.3 | 0~+0.3 | |

20-1000°CThermal Expansich10-6/°C | 1.25 | 1.25 | 1.25 | 1.25 | |

Thermal Conductivity (W/MK) 1000°C | 1.74 | 1.74 | 1.44 | 1.44 | |

- Q: Why will expand when heated brick

- In the process of SiO2 drying, the four crystalline transformation points of 117, 163, 180~270 and 573 DEG C are found, among which the volume expansion caused by the 180~270 is the largest.

- Q: How much is the highest melting point of silicon?

- Acidic silica brick refractories, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. More than 94% silica content.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- This is a kind of refractory material is divided into three types: semisilica brick (A12O315 ~ 30%), clay brick (A12O330 ~ 48%), high aluminum brick (A12O3>48%).

- Q: What role does silica play in refractories?

- The production of clay brick refractory clay raw material is natural, its main mineral is kaolinite (formula Al2O3 - 2SiO2 - 2H2O), clay brick containing SiO2 in 45% ~ 65%, belongs to the weak acid refractory materials, have a certain ability to resist acid slag, but easy to be alkaline slag erosion.

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: The formula in the refractory brick, and firing curve, who knows?

- By silica powder, 81-85%, perlite 15-19%, plus the total weight of the main raw materials of the following accessories

Send your message to us

Silica Brick for Glass Furnace Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords