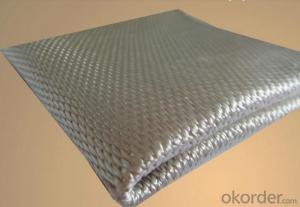

Glass Fiber Textiles - Heat Insulation Refractory Welding Pillow Fiberglass Fabric 550C-1000C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Welding Pillow fiberglass fabric made

Welding pillow, fire resistance pillow, it is made of fiberglass

Description:

Welding pillow, fire resistance pillow, it is made of fiberglass and insert with glass wool or ceramic wool, sewing it into pillow, it is good welding products while need pillow shape fire resistance.

We can manufacture all kinds of welding pillor, fire resistance pillow as per customer request. Just contact our sales for details.

Outside Materials : fiberglass fabrics, Silica fabrics, heat treated fiberglass fabrics, silicone coated fiberglass fabrics, Ceramic fiber fabric, Carbonizedfiber fabrics, Aluminum coated fiberglass fabrics, Acrylic coated fiberglass fabrics.

Inside Materials: Glass fiber wool, ceramic fiber wool

Temperature resistance: 500 Deg. C . to 1000 Deg. C.

Size: as per customer request

- Q: Can glass fiber textiles be used in the production of protective clothing?

- Yes, glass fiber textiles can be used in the production of protective clothing. Glass fiber textiles have strong resistance to high temperatures, fire, and chemicals, making them suitable for protective clothing in industries such as firefighting, welding, and chemical handling. They provide excellent insulation and can offer protection against heat, flame, and hazardous substances, enhancing the safety of individuals wearing such clothing.

- Q: Can glass fiber textile be used indoors?

- Yes, glass fiber textile can be used indoors. Glass fiber textiles, also known as fiberglass textiles, are versatile materials that can be used in various indoor applications. They are commonly used for insulation, soundproofing, and as reinforcement in walls, ceilings, and floors. Glass fiber textiles have excellent thermal and acoustic properties, making them suitable for creating a comfortable and energy-efficient indoor environment. Additionally, they are fire-resistant and do not release toxic gases when exposed to high temperatures, making them safe for indoor use. Overall, glass fiber textiles are widely used in construction and interior design industries to enhance the performance and aesthetics of indoor spaces.

- Q: Can glass fiber textile be used in aerospace interiors?

- Yes, glass fiber textile can be used in aerospace interiors. Glass fiber textiles have a number of properties that make them suitable for aerospace applications. Firstly, they are lightweight, which is essential in aerospace design to ensure fuel efficiency and reduce overall weight of the aircraft. Additionally, glass fiber textiles are known for their strength and durability, making them capable of withstanding the demanding conditions of aerospace environments. Glass fiber textiles also have good insulation properties, which is important for maintaining a comfortable and controlled interior temperature in the aircraft. They are resistant to heat and fire, which is crucial for ensuring safety in the event of a fire or high-temperature incident. Furthermore, glass fiber textiles can be easily molded and shaped into different forms, allowing for customized designs and integration into various parts of the aerospace interior, such as seat covers, cabin linings, wall panels, and floorings. They can also be treated with special coatings to enhance their resistance to abrasion, moisture, and chemicals. Overall, glass fiber textile is a versatile material that meets the stringent requirements of aerospace interiors in terms of weight, strength, durability, insulation, fire resistance, and design flexibility. Its use in aerospace interiors has proven to be effective and beneficial for both manufacturers and passengers.

- Q: What are the different surface finishes available for glass fiber textiles?

- There are several different surface finishes available for glass fiber textiles, depending on the intended application and desired characteristics. One common surface finish is a polymer sizing or finish, which is applied to the glass fibers during manufacturing. This finish helps to protect the fibers from damage during processing and handling, and can also improve their compatibility with other materials, such as resins or coatings. Another surface finish option is a thermal or heat-resistant coating, which is typically applied to glass fiber textiles that will be exposed to high temperatures. This coating helps to enhance the textile's ability to withstand heat and prevents the fibers from melting or degrading. A third type of surface finish is a water-resistant or hydrophobic treatment. This treatment can be applied to glass fiber textiles to make them resistant to water absorption, which can be beneficial in applications where moisture resistance is important, such as outdoor fabrics or insulation materials. Additionally, there are surface finishes available that provide specific properties like flame resistance, electrical conductivity, or antimicrobial properties. These finishes are typically applied to glass fiber textiles to enhance their performance in particular applications. It is important to note that the specific surface finishes available for glass fiber textiles can vary depending on the manufacturer and the intended use of the textile. Therefore, it is advisable to consult with a supplier or manufacturer to determine the most suitable surface finish for a particular application.

- Q: How do glass fiber textiles affect breathability?

- Glass fiber textiles can significantly reduce breathability due to their dense and non-porous nature. Unlike natural fibers, glass fibers do not allow air to easily pass through, thus restricting airflow and ventilation. This can result in reduced breathability and increased heat and moisture buildup, making the fabric less comfortable to wear in terms of breathability.

- Q: Can glass fiber textile be knitted?

- No, glass fiber textile cannot be knitted. Glass fiber textiles are made of tiny glass fibers that are woven together to create a strong and durable material. Knitting, on the other hand, is a technique where loops of yarn are interlaced to form a fabric. The flexibility and stretchiness of knitting is not suitable for glass fibers, which are rigid and do not have the same properties as yarn. Therefore, glass fiber textiles are typically made using weaving techniques rather than knitting.

- Q: Are glass fiber textiles resistant to shrinkage during washing?

- Yes, glass fiber textiles are generally resistant to shrinkage during washing. Due to their inherent properties, such as high tensile strength and heat resistance, glass fiber textiles typically maintain their shape and size after being washed.

- Q: Can glass fiber textiles be used in wall coverings?

- Yes, glass fiber textiles can be used in wall coverings. Glass fiber textiles, also known as fiberglass textiles, are commonly used in various applications including wall coverings. They offer several advantages such as fire resistance, durability, and thermal insulation properties. Glass fiber textiles can be woven into different patterns and designs, making them versatile for use in wall coverings. They are also resistant to moisture and mold growth, which makes them suitable for areas with high humidity. Additionally, glass fiber textiles can provide acoustic insulation, reducing noise transmission through walls. Overall, glass fiber textiles are a viable option for wall coverings due to their functional and aesthetic properties.

- Q: Can glass fiber textiles be treated with flame retardants?

- Yes, glass fiber textiles can be treated with flame retardants. Flame retardants are chemicals that are applied to materials to reduce their flammability and slow down the spread of fire. While glass fiber textiles are inherently fire-resistant due to the properties of glass, treating them with flame retardants can provide an additional level of fire protection. The flame retardant treatment can help prevent the fabric from catching fire or burning easily, making it more resistant to flames and reducing the risk of fire-related accidents. This is particularly useful in applications where fire safety is a concern, such as in the manufacturing of protective clothing, curtains, upholstery, or other textile products that need to meet certain fire safety standards.

- Q: Are glass fiber textiles recyclable?

- Yes, glass fiber textiles are recyclable. Glass fiber textiles, also known as fiberglass, can be recycled by melting down the fibers and reforming them into new products. The recycling process involves sorting the glass fiber textiles, removing any impurities, and then melting them at high temperatures to create molten glass. This molten glass can then be spun into new fibers or molded into different shapes for various applications. Recycling glass fiber textiles not only helps to reduce waste and conserve resources but also has environmental benefits, as it reduces the need for raw materials and energy-intensive manufacturing processes.

Send your message to us

Glass Fiber Textiles - Heat Insulation Refractory Welding Pillow Fiberglass Fabric 550C-1000C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords