Glass Fiber Textile Micropore Insulation Board - Heat Insulation Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | (Mainland) | Brand Name: | |

| Model Number: | 1000 | coating: | alumina foil/glass fiber cloth | Dimension: | 1000*500*10/20/30/40/50 mm |

| Density: | 300kg/m3 |

Packaging & Delivery

| Packaging Details: | wooden box |

| Delivery Detail: | 15 days after receipt of pre-payment |

Specifications

With heat-resistant inorganic fiber as reinforcing material combined with binders, NATI nanometer micro-heat conduction material

Introduction for Micropore Insulation Board ,Heat Insulation materials

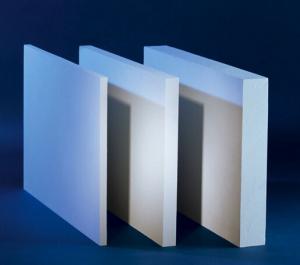

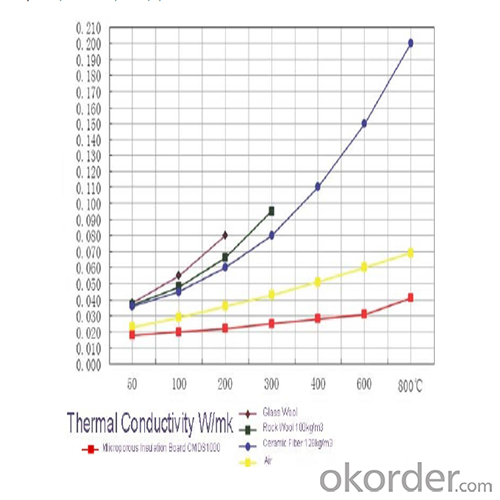

With heat-resistant inorganic fiber as reinforcing material combined with binders, NATI nanometer micro-heat conduction material is made of nanometer porous high-temperature resistant material and functional material with heat shield function through the combination of nanotechnology and special techniques. It has extremely low thermal conductivity that is just as one forth to one tenth that of ceramic fibre thermal insulation material.

Characteristics:

*High temperature resistance.

*Low thermal conductivity.

*Eco-friendliness and safety.

*Low thermal storage.

*Long service life.

Typical Application:

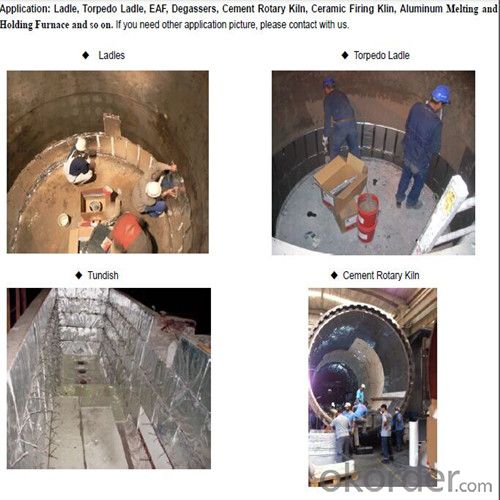

*It is widely used in various industries such as steel, petrochemical

Chemical & Physical Data:

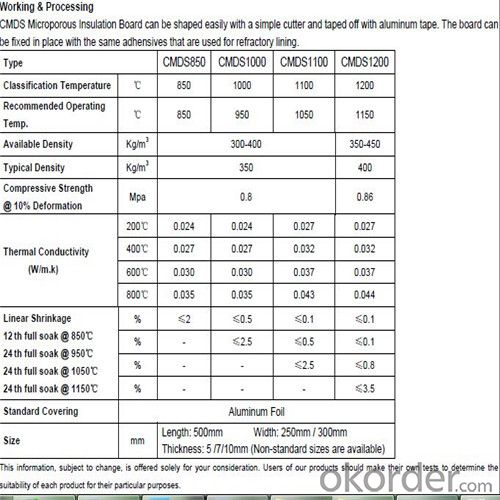

Type | 1000 NATI Micropore Board |

Bulk Density (kg/m3) | 300-350 |

Pressure Strength (MPa) | 0.7 |

Permament Linear Shrinkage %(800℃×6 hour) | 3.5% |

Thermal Conductivity (W/m.K) | 0.020(at 100 ℃) |

0.025(at 200 ℃) | |

0.028(at 400 ℃) | |

0.032(at 600 ℃) | |

0.037(at 800 ℃) |

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q: The antibacterial effect of bamboo fiber fabric is because it has been added with a kind of assistant, not the yarn of bamboo fiber itself

- According to the truth, natural bamboo fiber has a certain antibacterial and bactericidal effect, but the problem is that most of the so-called bamboo fiber is not natural bamboo fiber

- Q: What are the different finishes available for glass fiber textiles?

- Glass fiber textiles offer a range of finishes, each with its own unique properties and applications. Let's explore some of the most common finishes available: 1. Sizing: This finish enhances the handling and processing characteristics of glass fiber textiles. By reducing fiber-to-fiber friction, it facilitates easier handling and weaving. Additionally, sizing temporarily shields the textile from abrasion and mechanical damage during processing. 2. Silane Finish: Silane, a commonly used chemical compound, acts as a finish for glass fiber textiles. It improves adhesion between the glass fibers and the matrix material in composite applications. Furthermore, silane finishes enhance the wetting properties of the fibers, allowing for better resin impregnation during composite processing. 3. Anti-static Finish: Glass fiber textiles can be treated with an anti-static finish to prevent the accumulation of static electricity. This is particularly valuable in applications where static electricity can cause issues, such as in the manufacturing of electronic components or in cleanrooms. 4. Fire-resistant Finish: To enhance their resistance to flame and heat, glass fiber textiles can be treated with fire-resistant finishes. These finishes offer added safety in applications where fire hazards are present, such as in the construction industry or in protective clothing. 5. Water-repellent Finish: Applying a water-repellent finish to glass fiber textiles makes them resistant to water absorption. This prevents the textile from becoming heavy and wet, thereby preserving its performance and durability. 6. UV-resistant Finish: By treating glass fiber textiles with UV-resistant finishes, they can be shielded from the harmful effects of sunlight. These finishes protect the fibers from degradation and extend the textile's lifespan, making it suitable for outdoor applications. It is worth noting that different finishes can be combined to meet specific performance requirements. For instance, a glass fiber textile may feature both a silane finish for improved adhesion in composite applications and a fire-resistant finish for heightened safety. The choice of finish depends on the intended application and the desired properties of the textile.

- Q: How does glass fiber textile perform in terms of dimensional stability?

- Glass fiber textile excels in terms of dimensional stability, thanks to its innate characteristics like superior tensile strength and minimal thermal expansion. As a result, it experiences negligible shrinkage or expansion when exposed to fluctuations in temperature or humidity. This quality renders it a superb choice for applications demanding accurate and consistent measurements, as it upholds its shape and size consistently over time. Moreover, glass fiber textile resists stretching or sagging even under heavy loads, further augmenting its dimensional stability. All in all, glass fiber textile is renowned for its ability to preserve its form and dimensions, establishing itself as a highly dependable material across various industries including construction, aerospace, and automotive.

- Q: Why wool fibers and their fabrics have shrinkage properties? What are their advantages and disadvantages? What are the sizes and sizes of wool fabrics?...

- In the damp heat or chemical conditions, to be repeated as friction extrusion, the directional friction effect, keep the fiber finger movement and fiber entanglement in a certain direction slowly creeping into engagement. With wool felt, wool fabric shrink tightly.The wool fabric can be made into a rich, soft and warm fabric, but the shrinkage affects the dimensional stability after washing, and it is disadvantageous to the thin fabric which requires fine weaveThe size of cashmere is related to the quality of wool and external conditions (heat and moisture, mechanical external force)

- Q: Can glass fiber textiles be used in reinforcement of nanocomposites?

- Glass fiber textiles have the capability to reinforce nanocomposites. Known for their exceptional strength, stiffness, and impact resistance, glass fibers are an ideal choice for enhancing materials. In contrast, nanocomposites consist of a matrix material and nanoscale fillers like nanoparticles or nanotubes, which improve the composite's mechanical and physical properties. Incorporating glass fiber textiles into nanocomposites allows the resulting material to benefit from both the strength and stiffness of the fibers, as well as the enhanced properties provided by the nanofillers. The fibers act as reinforcement, enhancing the overall mechanical performance and durability of the nanocomposite. Meanwhile, the nanofillers contribute to specific properties such as thermal conductivity, electrical conductivity, or flame resistance. Additionally, the compatibility between glass fibers and the matrix material of the nanocomposite is typically high, ensuring effective load transfer and improved mechanical properties. This compatibility guarantees that the glass fibers are efficiently integrated into the nanocomposite structure, providing the desired reinforcement. In conclusion, glass fiber textiles are indeed suitable for reinforcing nanocomposites. When combined with nanofillers, they offer improved mechanical performance, making them applicable in various industries.

- Q: Are glass fiber textiles resistant to moisture vapor transmission?

- Yes, glass fiber textiles are generally resistant to moisture vapor transmission.

- Q: Is it OK to make a model with fiberglass cloth and paint brush on the model?

- Hello Yes, but the effect is not very good. It is better to use ABS plastic material, which is beautiful and durable!

- Q: How do glass fiber textiles contribute to chemical stability?

- Glass fiber textiles play an important role in maintaining chemical stability through various means. Firstly, their inherent resistance to chemical attack sets them apart from organic fibers like cotton or polyester. Unlike these materials, glass fibers do not degrade or react chemically when exposed to most acids, bases, or solvents. This makes them an ideal choice for applications that demand chemical stability. In addition, glass fibers exhibit a low coefficient of thermal expansion, meaning they do not significantly expand or contract with temperature changes. This characteristic is crucial for ensuring chemical stability, as it guarantees that the structure of the textile remains intact even under extreme temperature variations. By maintaining dimensional stability, glass fiber textiles can effectively resist chemical degradation caused by thermal stress. Furthermore, glass fibers are non-combustible, meaning they do not burn or support combustion. This attribute is particularly important in chemical environments where fire hazards are present. By eliminating the risk of combustion, glass fiber textiles contribute significantly to the overall chemical stability of a system. Moreover, glass fibers possess excellent resistance to UV radiation, which is known to cause degradation in many materials. This UV resistance ensures that glass fiber textiles retain their structural integrity and performance even after prolonged exposure to sunlight or other sources of UV radiation. Taken together, the chemical stability of glass fiber textiles can be attributed to their inherent resistance to chemical attack, low coefficient of thermal expansion, non-combustible nature, and UV resistance. These properties make glass fiber textiles an exceptional choice for applications where chemical stability is a critical requirement.

- Q: Can glass fiber textiles be used in soundproofing applications?

- Glass fiber textiles, also referred to as fiberglass, possess exceptional acoustic properties and can be utilized for soundproofing purposes. They can absorb sound waves and diminish their transmission through walls, floors, and ceilings. This renders them an ideal material for soundproofing in various settings like recording studios, theaters, offices, and residential buildings. Lightweight and flexible, glass fiber textiles can be effortlessly installed as a layer or panel on walls or ceilings. They exhibit a high sound absorption coefficient, enabling them to effectively absorb a substantial amount of sound energy. Consequently, this aids in reducing reverberation and echo within a space, leading to enhanced sound quality and speech intelligibility. Additionally, glass fiber textiles possess the added advantage of being fire-resistant, a critical factor for safety in soundproofing installations. They possess a high melting point and do not emit toxic fumes when exposed to fire, making them a secure choice for soundproofing applications. To summarize, glass fiber textiles are a suitable material for soundproofing purposes due to their remarkable acoustic properties, easy installation, and fire resistance. They can significantly diminish noise transmission, enhance sound quality, and establish a more comfortable and tranquil environment.

- Q: How do glass fiber textiles resist insects?

- Glass fiber textiles resist insects because the material is not edible or appealing to them, and its smooth surface makes it difficult for insects to climb or attach their eggs. Additionally, glass fiber textiles do not provide a suitable environment for insects to thrive due to their lack of moisture retention and resistance to mold or mildew.

Send your message to us

Glass Fiber Textile Micropore Insulation Board - Heat Insulation Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords