Glass Fiber Textile Epoxy Glass Cloth Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 800 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

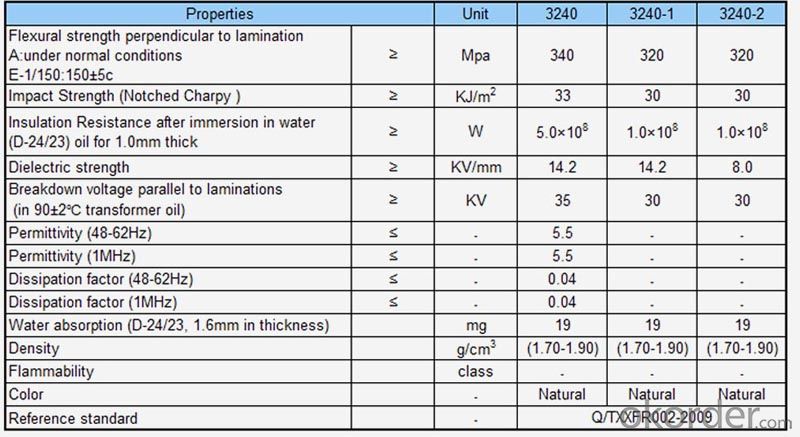

Laminate Type ◆ 3240 G10 G11 FR-4 FR-5 ◆ Thickness:0.5mm-90mm ◆ Size:1000×1200mm 1000×2000mm 1000×2400mm Rod/Tube Type ◆ 3721 3722 3723 3724 3725 3840 3841 3520 3526 3640 ◆ Diameter:6mm 8mm 10mm-200mm ◆ Length:1000mm | |

| 3240 * Temperature grade: B glass (130℃) * Color: nature, red, green, black * Thickness: 0.5-80mm * Size: 1020x2040mm | 3240-1 & 3240-2 * Temperature grade: B glass (130℃) * Color: nature,yellow * Thickness: 0.5-80mm * Size: 1020x2040mm |

| |

| F880A F881A * Temperature grade: B glass (130℃) * Color: nature, green * Thickness: 0.5-80mm * Size(mm): 1020x1220 1020x2040 1220x2470 | F882A F883A * Temperature grade: F glass (155℃) * Color: nature, green * Thickness: 0.5-80mm * Size(mm): 1020x1220 1020x2040 1220x2470 |

- Q: Can glass fiber textiles be used in the production of protective clothing?

- Yes, glass fiber textiles can be used in the production of protective clothing. Glass fiber textiles are known for their high strength and heat resistance properties, making them suitable for applications where protection against heat, flames, and molten metals is required. The use of glass fiber textiles in protective clothing can provide a layer of insulation and protection to the wearer, reducing the risk of burn injuries. Additionally, glass fiber textiles are also resistant to chemicals, making them suitable for use in industries where exposure to hazardous chemicals is a concern. Overall, the use of glass fiber textiles in the production of protective clothing can enhance the safety and well-being of individuals working in high-risk environments.

- Q: Can glass fiber textile be used in architectural applications?

- Yes, glass fiber textile can be used in architectural applications. It is commonly used for creating lightweight and flexible structures such as tensile membranes, facades, and canopies. Glass fiber textile offers excellent strength, durability, and transparency, making it suitable for enhancing the aesthetics and functionality of architectural designs. It is also resistant to weather and environmental conditions, making it a viable choice for long-lasting architectural applications.

- Q: How is glass fiber textile used in the construction industry?

- Glass fiber textiles, also known as fiberglass textiles, are extensively used in the construction industry for a variety of purposes. These textiles are made from fine strands of glass fiber that are woven together to form a flexible and strong material. One of the main applications of glass fiber textiles in construction is for reinforcing materials. When added to concrete or other construction materials, these textiles provide enhanced strength and durability. They help to prevent cracking and improve the overall structural integrity of buildings and infrastructure. Glass fiber textiles can also be used to reinforce walls, floors, and roofs, ensuring that they can withstand the forces and stresses placed upon them. Another common use of glass fiber textiles is in insulation. These textiles have excellent thermal properties, making them highly effective in preventing heat transfer. They can be used as insulation blankets or as loose fill insulation to improve energy efficiency and reduce heating and cooling costs. Additionally, glass fiber textiles have good sound absorption qualities, making them useful for reducing noise levels in buildings. Glass fiber textiles are also used for fire resistance in construction. Due to their high melting point and low thermal conductivity, they provide effective fire protection when used as insulation or as fire-resistant barriers. This can help to slow down the spread of fire and provide valuable time for occupants to evacuate safely. In addition to these applications, glass fiber textiles are used for waterproofing and moisture control in construction. They can be used as a protective layer to prevent water penetration and moisture damage. This is particularly important in areas such as basements, roofs, and bathrooms, where water can be a major concern. Overall, glass fiber textiles play a crucial role in the construction industry by providing strength, insulation, fire resistance, and moisture control. Their versatility and durability make them an ideal choice for various construction applications, ensuring the longevity and safety of buildings and infrastructure.

- Q: How do glass fiber textiles resist fading?

- Glass fiber textiles resist fading because they are made from inorganic materials that are inherently resistant to UV radiation and do not absorb or react with sunlight.

- Q: Can glass fiber textiles cause skin irritation?

- Yes, glass fiber textiles can cause skin irritation. Glass fibers are tiny strands of glass that can be woven into fabrics to create textiles. When these fibers come into contact with the skin, they can cause irritation, itching, and redness. This is because glass fibers have sharp edges that can pierce the skin, leading to discomfort and irritation. Additionally, the fibers can also release microscopic particles into the air, which can further irritate the skin and respiratory system when inhaled. It is important to take precautions when working with or wearing glass fiber textiles to minimize skin irritation, such as wearing protective gloves and clothing, and avoiding direct contact with the skin.

- Q: What is the durability of glass fiber textiles?

- Glass fiber textiles are known for their exceptional durability. The durability of these textiles can be attributed to the inherent properties of glass fibers, such as their high tensile strength and resistance to chemical degradation. Glass fibers are made from molten glass, which is spun into thin strands and then woven or knitted together to form a textile. This process creates a material that is incredibly strong and resistant to wear and tear. Glass fiber textiles have a high tensile strength, meaning they can withstand a significant amount of pulling or stretching force without breaking. This makes them ideal for use in applications where strength and durability are required, such as in the construction industry for reinforcement in concrete and composites, or in the manufacturing of various industrial products. In addition to their strength, glass fiber textiles are also highly resistant to chemical degradation. They are not affected by exposure to most chemicals, including acids, alkalis, and solvents. This resistance to chemicals allows glass fiber textiles to maintain their integrity and performance even in harsh environments. Furthermore, glass fiber textiles are also known for their resistance to UV radiation and extreme temperatures. They do not degrade or weaken when exposed to sunlight or extreme heat, making them suitable for outdoor applications and high-temperature environments. Overall, glass fiber textiles have a long lifespan and can withstand the test of time, making them a durable choice for a wide range of applications.

- Q: What are the different weaving patterns used for glass fiber textile?

- There are several different weaving patterns commonly used for glass fiber textiles, each with its own unique characteristics and applications. Some of the most common weaving patterns for glass fiber textiles include plain weave, twill weave, satin weave, leno weave, and basket weave. 1. Plain weave: This is the simplest and most common weaving pattern. It involves interlacing the warp and weft yarns in an over-under pattern, creating a balanced and strong fabric. Plain weave glass fiber textiles are often used in applications where strength and durability are important, such as reinforcement materials in composites. 2. Twill weave: This pattern is characterized by a diagonal line or rib effect on the fabric surface. Twill weave glass fiber textiles are known for their excellent drapability and drapeability, making them suitable for applications like clothing, upholstery, and reinforcement in curved composite structures. 3. Satin weave: Satin weave glass fiber textiles have a smooth and lustrous surface due to the way the yarns are interlaced. This weaving pattern creates long floats on the fabric surface, resulting in a soft and flexible material. Satin weave glass fiber textiles are commonly used in high-end applications such as luxury apparel, automotive interiors, and decorative fabrics. 4. Leno weave: Leno weave is a unique pattern that involves crossing two warp yarns over each other and then interlacing with the weft yarn. This creates a stable and open fabric structure, often used in applications that require good ventilation and transparency, such as filters, mosquito nets, and curtains. 5. Basket weave: In basket weave, two or more warp yarns are woven together as one, and the weft yarns are interlaced between these pairs. This creates a fabric with a distinctive checkerboard-like appearance. Basket weave glass fiber textiles are commonly used in applications that require a balance between strength and flexibility, such as bags, upholstery, and reinforcement in composite structures. These different weaving patterns offer a variety of properties and characteristics that make them suitable for different applications. The choice of weaving pattern for glass fiber textiles depends on factors such as desired strength, flexibility, drapeability, transparency, and surface appearance.

- Q: Are glass fiber textiles resistant to insects?

- Yes, glass fiber textiles are generally resistant to insects due to the inorganic and non-nutritive nature of glass, which does not attract or provide a food source for insects.

- Q: How do glass fiber textiles contribute to lightweight construction?

- Glass fiber textiles contribute to lightweight construction by providing strength and durability while being significantly lighter than traditional construction materials. The use of glass fiber textiles in building components such as walls, roofs, and facades reduces the overall weight of the structure, making it more efficient and cost-effective. Additionally, the flexibility and versatility of glass fiber textiles allow for design freedom and easy installation, further enhancing their contribution to lightweight construction.

- Q: What are the different applications of glass fiber textiles?

- Glass fiber textiles have a wide range of applications due to their unique properties and versatility. Some of the different applications of glass fiber textiles include: 1. Insulation: Glass fiber textiles are commonly used as insulation materials in various industries such as construction and automotive. They have excellent thermal insulation properties, making them an ideal choice for insulating walls, roofs, pipes, and other structures. 2. Composites: Glass fiber textiles are widely used as reinforcement materials in the manufacturing of composite materials. When combined with resins or polymers, they enhance the strength, stiffness, and durability of the final product. This makes them suitable for applications in aerospace, automotive, marine, and sporting goods industries. 3. Filtration: Glass fiber textiles are commonly used in air and liquid filtration systems. They have a high porosity, which allows them to efficiently trap and remove particles and impurities from fluids and gases. This makes them an essential component in filters for water purification, air conditioning systems, and industrial processes. 4. Electrical insulation: Glass fiber textiles have excellent electrical insulation properties, making them an ideal choice for applications in the electrical and electronics industry. They are used as insulation materials in cables, circuit boards, transformers, and other electrical components to prevent electrical current leakage and ensure safety. 5. Reinforcement: Glass fiber textiles are used as reinforcement materials in various applications where strength and durability are required. They are commonly used in the construction industry for reinforcing concrete structures, such as bridges, buildings, and roads. They can also be found in the manufacturing of fiberglass tanks, pipes, and other structural components. 6. Thermal protection: Glass fiber textiles have excellent resistance to high temperatures, making them suitable for applications requiring thermal protection. They are used as heat shields and fire-resistant barriers in industries such as aerospace, automotive, and firefighting. They can also be found in protective clothing, such as heat-resistant gloves and suits. Overall, glass fiber textiles play a crucial role in numerous industries due to their insulation, reinforcement, filtration, electrical insulation, and thermal protection properties. Their versatility and ability to enhance the performance of various materials make them indispensable in a wide range of applications.

Send your message to us

Glass Fiber Textile Epoxy Glass Cloth Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 800 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords