Glass Fiber Reinforced Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | HCS | Color: | white | Apparent Density: | 220 +/- 10% |

| Heat Conductivity: | 0.060 | Highest Working Temperature: | 1050 | Material: | Xonotlite and reinforced glass fiber |

Packaging & Delivery

| Packaging Details: | Standard Fumigation Wooden pallet or Carton Package with Plastic Sheet inside |

| Delivery Detail: | Generally within 2 weeks after receipt of deposit |

Specifications

Microporous calcium silicate insulation board

experienced manufacturer

Size:1000*600mm,600*150mm

ISO9001:2008

Microporous calcium silicate insulation board

It is mixed with Xonotlite and reinforced glass fibre with high service temp. (1050 celsius),good heat insulation, low bulk density, high strength, good durability and so on.

Product characteristics:

² Good durability, can bear high temperature within the limit of continuous heat load,

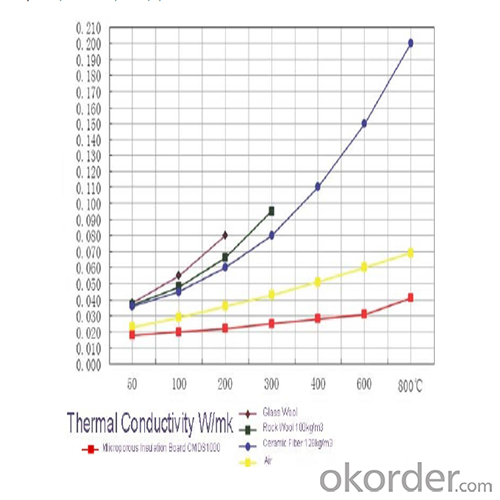

² Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

² Light weight, high strength. It is the highest in these hard thermal insulation products.

² Better durability, use for a long time without powder.

² Construction with ordinary carpenter applicability, tools can be optional cut products.

² Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

² Fear water, but after drying also can be used.

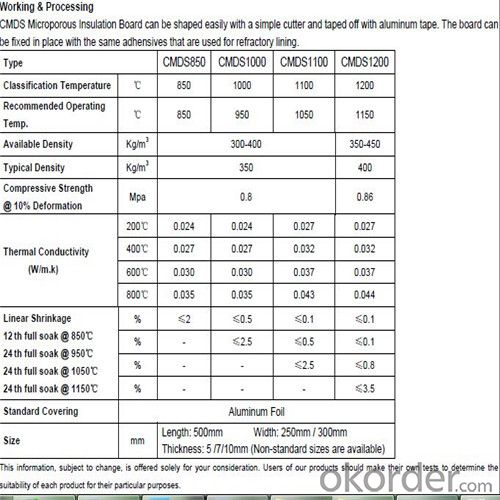

HCS Physical Performance Index

Items | Unit | HCS-170 | HCS-220 | HCS-270 |

Bulk Density | Kg/m3 | 170(±10%) | 220(±10%) | 270(±10%) |

Pressure Strength | MPa | ≥0.40 | ≥0.50 | ≥0.60 |

Flexural Strength | MPa | ≥0.30 | ≥0.35 | ≥0.40 |

Thermal Conductive | W/m.k | ≤0.048 +0.00011t | ≤0.050 +0.00011t | ≤0.056 +0.00011t |

Temp. limit | degrees | 1000 | 1050 | 1050 |

Linear Shrinkage | % | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) |

Block Sizes and Dimensional Tolerances

Length(±3mm) | Width(±3mm) | Thickness(+2mm,—1.5mm) |

610 | 303,300,150 | 25—140 |

600 | 300 | 25—140 |

400 | 250 | 25—140 |

1000 | 500 | 25—140 |

1200 | 600 | 25—140 |

We also supply special size and type.

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q: Can glass fiber textiles be used for reinforcement in ceramics?

- Glass fiber textiles, or fiberglass, possess exceptional characteristics including remarkable tensile strength, resistance to high temperatures, and chemicals. These properties render them appropriate for reinforcing ceramics, thereby augmenting the ceramics' strength and durability. Additionally, glass fiber textiles can be woven effortlessly into different shapes and sizes, providing tailor-made reinforcement solutions for diverse ceramic applications. In summary, glass fiber textiles present an economical and effective means of enhancing the mechanical properties of ceramics, making them a highly favored option for reinforcing ceramic products.

- Q: What are some common applications of glass fiber textiles?

- Some common applications of glass fiber textiles include reinforcement materials in composites, insulation for buildings and pipelines, protective clothing and equipment, filtration systems, and electrical insulation.

- Q: Can glass fiber textile be used in spacecraft construction?

- Glass fiber textiles, also known as fiberglass, are a suitable material for constructing spacecraft. They are lightweight and have high tensile strength, making them ideal for various applications in the aerospace industry. In spacecraft construction, they are commonly used as reinforcement material in composite structures. Using glass fiber textiles in spacecraft construction has several advantages. Firstly, they possess excellent mechanical properties, including a high strength-to-weight ratio and stiffness. These properties are crucial for maintaining structural integrity and reducing the overall weight of the spacecraft. This is particularly important in the aerospace industry, where minimizing weight is a top priority to maximize fuel efficiency. In addition, glass fiber textiles offer good thermal and electrical insulation properties. This makes them suitable for applications that require temperature control and electrical isolation. Such properties are essential in spacecraft construction, as space's extreme temperatures and harsh environments can pose significant challenges to a spacecraft's integrity and performance. Moreover, glass fiber textiles are resistant to corrosion. This is beneficial in space, where exposure to different elements and harsh conditions can degrade materials over time. Their corrosion resistance helps extend the lifespan of spacecraft components, reducing the need for frequent repairs or replacements. Overall, glass fiber textiles provide a reliable and cost-effective solution for constructing spacecraft. They possess the necessary strength, lightweight, thermal insulation, and corrosion resistance properties required for the demanding conditions of space exploration.

- Q: How do glass fiber textiles perform in terms of abrasion resistance?

- Glass fiber textiles have excellent abrasion resistance. Due to their strong and durable nature, they are able to withstand repeated friction and wear without easily deteriorating or losing their integrity. This makes them highly suitable for applications where resistance to abrasion is crucial, such as in protective clothing, industrial fabrics, and reinforcement materials in composites.

- Q: How do glass fiber textiles affect energy consumption?

- Glass fiber textiles can positively impact energy consumption in multiple ways. Firstly, glass fiber textiles have excellent insulation properties, which can help to reduce heat transfer through walls, roofs, and floors. This insulation capability allows for better temperature control inside buildings, reducing the need for heating or cooling systems and subsequently lowering energy consumption. Additionally, glass fiber textiles can also be used as reinforcement materials in the construction of wind turbine blades, helping to improve their efficiency and increase energy production from renewable sources. Overall, glass fiber textiles play a significant role in promoting energy efficiency and reducing energy consumption in various applications.

- Q: Is glass fiber textile waterproof?

- Although glass fiber textile lacks inherent waterproofing properties, it can acquire waterproofness by applying supplementary coatings or treatments. These additional measures aid in water repellency and prevent water infiltration into the fabric. Failure to employ these treatments may result in water absorption and wetting of the glass fiber textile. Hence, to achieve waterproofness, it is crucial to appropriately treat the glass fiber textile to render it water-resistant or waterproof.

- Q: Can glass fiber textiles be used in reinforcement of synthetic fibers?

- Yes, glass fiber textiles can be used in the reinforcement of synthetic fibers. Glass fibers are known for their high strength and stiffness, making them an ideal material for reinforcing synthetic fibers such as nylon, polyester, or polypropylene. The combination of glass fiber textiles with synthetic fibers enhances the overall strength and durability of the resulting composite material.

- Q: Can glass fiber textiles be felted?

- No, glass fiber textiles cannot be felted. Felt is a fabric made by matting, condensing, and pressing fibers together. It is typically made from animal fibers such as wool, which have natural scales that interlock when subjected to heat, moisture, and pressure. Glass fibers, on the other hand, are made from molten glass that is drawn into thin strands. These fibers do not have the same properties as animal fibers and therefore cannot be felted.

- Q: How do glass fiber textiles affect recycling processes?

- Glass fiber textiles can have both positive and negative effects on recycling processes. On one hand, glass fiber textiles are often made from recycled glass, which helps to reduce the amount of waste sent to landfills and conserves natural resources. Additionally, glass fibers are highly durable and resistant to degradation, making them suitable for recycling multiple times without losing their properties. However, glass fiber textiles can also pose challenges in the recycling process. The strong and rigid nature of glass fibers makes it difficult to separate them from other materials during recycling. This can lead to contamination of other recyclable materials, reducing their quality and market value. Furthermore, the small size of glass fibers can make them difficult to collect and handle in recycling facilities, potentially causing operational issues. To overcome these challenges, innovative recycling technologies and processes have been developed. For instance, advanced sorting technologies can help separate glass fibers from other materials more efficiently. Additionally, some recycling facilities use specialized equipment to shred glass fiber textiles into small particles, which can then be blended with other materials to create new products. In conclusion, glass fiber textiles have a mixed impact on recycling processes. While they contribute to the circular economy by using recycled glass and being recyclable themselves, their strong and rigid nature can complicate the recycling process. However, with the use of advanced technologies and proper handling, the recycling of glass fiber textiles can be optimized, leading to increased sustainability and resource conservation.

- Q: Can glass fiber textile be used in sporting goods?

- Glass fiber textiles prove to be a valuable asset in the realm of sporting goods. Their lightweight nature, robustness, and remarkable impact resistance enable them to cater to a wide range of applications within the sports industry. In fact, they find extensive utilization in the production of sports equipment, including tennis rackets, golf club shafts, hockey sticks, and bicycle frames. Incorporating glass fiber textiles in sporting goods serves to heighten performance, bolster durability, and enhance the overall safety of athletes.

Send your message to us

Glass Fiber Reinforced Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords