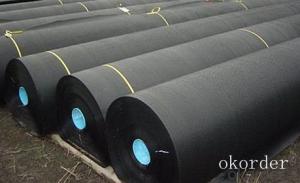

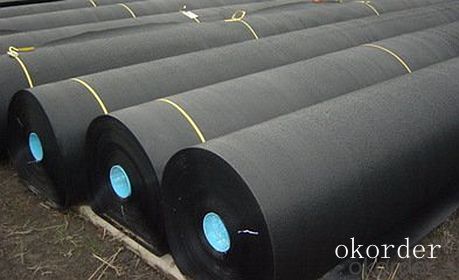

Geotextile Staples Reinforced Environmental Engineering HDPE Geomembrane Roll with High Quality for Potable Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Geomembrane with impermeable plastic film as a substrate, and non-woven geotextile composite made of impermeable material, which depends on the seepage properties of a impermeable plastic film performance. Is a kind of polymer chemistry flexible material, the proportion of small, extensible stronger ability to adapt to high deformation. Corrosion resistance, low temperature, frost good performance. Have better resistance to erosion, are not afraid of acid, alkali and salt erosion.

Thickness:

1mm-3mm

Length:

50-200m as customers' request

Width:

4m~9m

Standard:

ISO, CE

Feature:

Chemical Resistant

Surface:

Textured Surface

Product name:

hdpe geomembrane manufacturers

Keyword:

hdpe geomembrane manufacturers

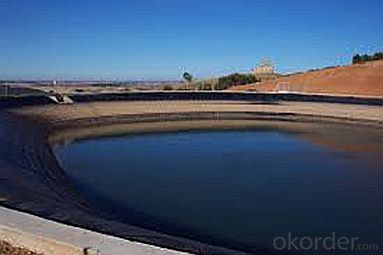

Application

1. high quality hdpe geomembrane use in agriculture

1. high quality hdpe geomembrane use in agriculture farm

3. high quality hdpe geomembrane use in shrimp ponds orLotus

4. high quality hdpe geomembrane use in Slope protection impervious

5. high quality hdpe geomembrane use in Landfill anti-seepage

6. high quality hdpe geomembrane use in Agricultural water reservoir:

7. high quality hdpe geomembrane for roof seepage control

Technical specifications of HDPE geomembrane:

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Where is the non-woven geotextile in the tunnel?

- The nonwoven geotextile is used to isolate the dome between the concrete and the waterproof layer in the tunnel.

- Q: What is the filament single-sided singeing geotextile

- Filament single-sided singeing geotextile is through a series of hot-rolling process will filament geotextile side of the filament fiber roll hot filament geotextile surface of the unity, thereby increasing the filament geotextile non-slip, anti- Tear resistance. Filament singeing geotextile is generally used for landfill, tailings and other projects with rough surface geomembrane with the use of friction coefficient to increase and improve anti-skid performance. Filament single-sided singeing geotextile is the first production of finished filament geotextile, and then through the professional equipment for single-sided singeing.

- Q: What are the key factors affecting the puncture resistance of geotextiles?

- The key factors affecting the puncture resistance of geotextiles include the type and thickness of the geotextile material, the tensile strength of the fibers used, the density of the fabric, and the presence of any protective coatings or additives. Additionally, the installation and construction methods, as well as the conditions and properties of the underlying soil or material, can also influence the puncture resistance of geotextiles.

- Q: What is the size of the filament geotextile? What are the characteristics of the application?

- What is the size of the filament geotextile? What are the characteristics of the application?

- Q: GB waterproof geotextile what price

- GB waterproof geotextile details please see

- Q: What are the different geotextile testing parameters?

- There are several different geotextile testing parameters that are used to evaluate the performance and quality of geotextiles. Some of the common parameters include tensile strength, puncture resistance, tear strength, permeability, apparent opening size, and UV resistance. These tests help determine the suitability of geotextiles for specific applications and ensure their durability and effectiveness in various geotechnical and civil engineering projects.

- Q: How do geotextiles improve the performance of embankments?

- Geotextiles improve the performance of embankments by providing reinforcement and stability to the soil structure. They act as a barrier against soil erosion, preventing the loss of soil particles and maintaining the integrity of the embankment. Geotextiles also allow water to pass through while retaining the soil, enhancing drainage and preventing water buildup that could weaken the embankment. Additionally, geotextiles distribute the load more evenly, reducing the potential for settling and improving overall stability of the embankment.

- Q: What are the different geotextile installation techniques in separation?

- The different geotextile installation techniques in separation include direct placement, trench installation, and overlay installation. Direct placement involves laying the geotextile directly on the subgrade or soil surface, providing separation between different layers of soil or aggregate. Trench installation involves placing the geotextile in a trench dug along the separation line, then backfilling the trench with soil or aggregate. This technique is commonly used in applications like road construction. Overlay installation involves placing the geotextile on top of an existing surface, such as an old road, to provide separation between the existing surface and a new layer of soil or aggregate. Each installation technique has its advantages and is chosen based on the specific project requirements.

- Q: Can geotextiles be used in underground pipe installation?

- Yes, geotextiles can be used in underground pipe installation. Geotextiles are often used as a protective barrier between the pipe and surrounding soil to prevent soil intrusion, enhance drainage, and provide additional support.

Send your message to us

Geotextile Staples Reinforced Environmental Engineering HDPE Geomembrane Roll with High Quality for Potable Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords