Geotextile Permeable Silt Fence with Pocket/Weed Barrier/Woven Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Silt Fence Description:

A silt fence, also referred to as a filter fence, is a structure composed primarily of geotechnical fabric and that is used as a form of sediment control.These temporary barriers are relatively low in cost, especially when compared to the damages they can prevent. They keep loose soils from traveling into local bodies of water and they also minimize the impact that various forms of development can have on surrounding wildlife.

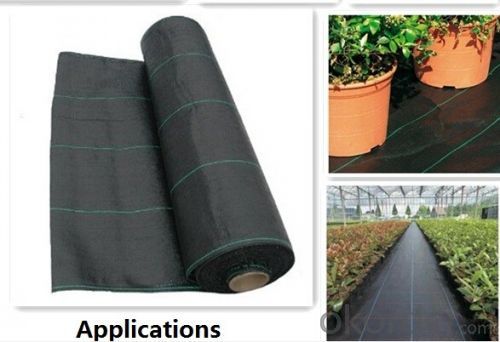

2. Weed Barrier Fabric Specification:

Weight: 80g/m2~400g/m2;

Width: 0.5m ~6m;

Length: 100m or as required;

3.Weed Barrier Fabric Functions and Features:

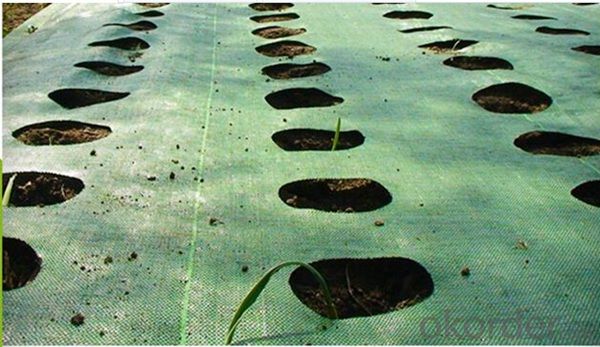

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

9)Fashionable design,high quality,competitive price

10)Long service life

4. Weed Barrier Fabric Usage:

1.Prevent leakage disposal in landfill or waste water or waste dregs disposing field.

2.River bank ,lake dam ,mine remainings ,resevoir ,tunnel ,liquid storage pool(pit ,mine)

3.Preventing leakage in subway ,basement ,tunnel ,hole .

4.Anti-salt leakage in roadbed and other ground sill.

5.The plane direction laying of dam ,the vertical direction laying for ground sill.used in the construction fence and waste material field.

6.Used in ground sill of road ,highway ,railway and waterproof layer of welling clay and wet collapsed loess.

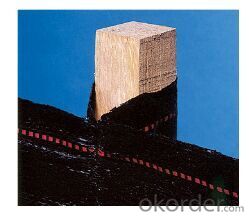

7.Preventing leakage on rooftop.

- Q: What are the key differences between woven and nonwoven geotextiles?

- The key differences between woven and nonwoven geotextiles lie in their manufacturing processes and physical characteristics. Woven geotextiles are made by interlacing yarns or fibers together to create a stable and strong fabric. On the other hand, nonwoven geotextiles are produced by bonding or felting fibers together without any weaving process. In terms of physical characteristics, woven geotextiles generally have higher tensile strength and puncture resistance due to their interlaced structure. They also offer better filtration properties as the open spaces between the woven yarns allow for effective water flow. Nonwoven geotextiles, however, have a higher permittivity, meaning they have a greater ability to allow water to pass through. Another notable difference is their durability. Woven geotextiles tend to be more resistant to UV degradation and offer better long-term performance, making them suitable for applications that require high strength and stability over time. Nonwoven geotextiles, although less durable, are often used for short-term projects or where filtration and separation are the main requirements. Overall, the choice between woven and nonwoven geotextiles depends on the specific application and desired properties. Woven geotextiles are typically favored for their strength and longevity, while nonwoven geotextiles are preferred for their filtration capabilities and cost-effectiveness in certain applications.

- Q: How do geotextiles help in stabilizing railroad tracks?

- Geotextiles help in stabilizing railroad tracks by providing reinforcement and separation between the subgrade and the ballast. They prevent the mixing of fine particles from the subgrade with the ballast, maintaining its stability and preventing track settlement. Additionally, geotextiles enhance drainage, reducing water accumulation and increasing the overall stability of the railroad tracks.

- Q: What are the advantages of using geotextiles in shoreline stabilization projects?

- There are several advantages of using geotextiles in shoreline stabilization projects. Firstly, geotextiles provide effective erosion control by preventing soil erosion and sedimentation. They act as a barrier that stabilizes the shoreline and prevents the loss of valuable land. Secondly, geotextiles are permeable, allowing water to pass through while still retaining soil particles. This promotes natural drainage and prevents the accumulation of water behind the shoreline, which can cause further erosion. Additionally, geotextiles are durable and resistant to degradation from environmental factors such as UV radiation and chemicals. This ensures a long-lasting solution for shoreline stabilization. Lastly, geotextiles are cost-effective compared to traditional methods like concrete or riprap. They require less maintenance and are easier to install, making them a more practical and efficient choice for shoreline stabilization projects.

- Q: What are the different types of geotextile installation equipment?

- Some common types of geotextile installation equipment include geotextile rollers, geotextile stitchers, geotextile spreaders, geotextile staplers, and geotextile tensioners. These tools are used to efficiently and effectively install geotextiles in various applications such as erosion control, soil stabilization, and drainage systems.

- Q: What are the different geotextile filter criteria?

- Some of the different geotextile filter criteria include permeability, pore size distribution, puncture resistance, durability, and chemical resistance. These criteria help determine the effectiveness of a geotextile in filtering water and preventing soil erosion.

- Q: Can geotextiles be used in landfill construction?

- Yes, geotextiles can be used in landfill construction. They are commonly used as liners, covers, and drainage materials in landfills to prevent soil erosion, control water flow, and improve stability and performance of the landfill structure.

- Q: How do geotextiles contribute to soil stabilization?

- Geotextiles contribute to soil stabilization by providing a barrier that prevents soil erosion, while still allowing water to drain through. They distribute the weight of the load evenly, reducing the chances of soil compaction and settling. Additionally, geotextiles help in reinforcing the soil, increasing its shear strength and stability.

- Q: Will the HDPE geomembrane, non-woven geotextile re-examination to detect what project? Is there a basis for testing? Thank you, hurry! The The

- CBR top breaking strength, vertical permeability coefficient ,,

- Q: Are geotextiles resistant to insect infestation?

- Yes, geotextiles are generally resistant to insect infestation. Their synthetic materials and tightly woven structure make it difficult for insects to penetrate and nest within the fabric. However, some types of geotextiles may still be susceptible to infestation in certain conditions, so it is recommended to choose insect-resistant variants or take appropriate preventive measures if necessary.

- Q: What are the different methods of geotextile testing for strength and durability?

- Some of the different methods of geotextile testing for strength and durability include grab tensile testing, wide-width tensile testing, puncture testing, tear resistance testing, and abrasion resistance testing. These tests help determine the mechanical properties of geotextiles and assess their ability to withstand forces and maintain their integrity over time.

Send your message to us

Geotextile Permeable Silt Fence with Pocket/Weed Barrier/Woven Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords