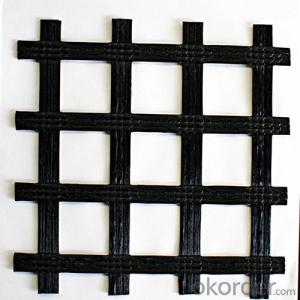

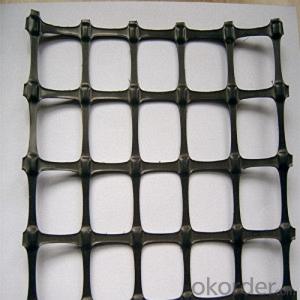

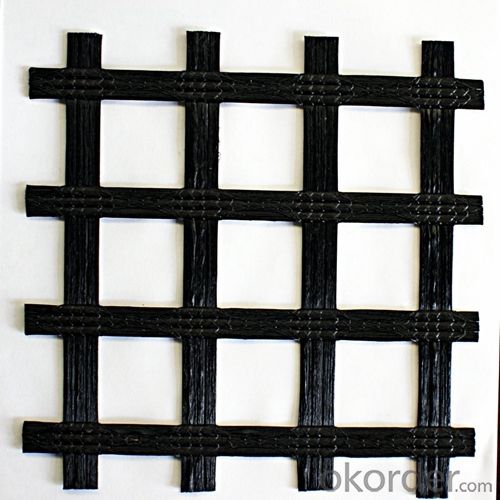

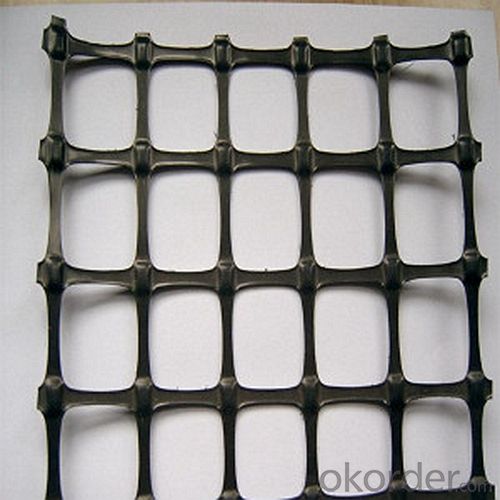

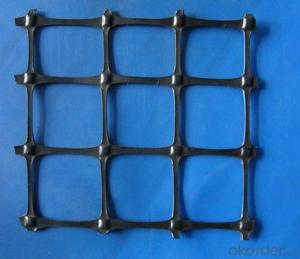

Geotextile Paper Fiberglass Geogrid for Roadbed Reinforcement in Highway, Railway, and Municipal Road

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Model Number:

EGA50-50, EGA80-80, EGA100-100

Material:

Fiberglass

Coating:

asphalt

feature:

High flexibility and large range

Fiberglass Geogrid Application

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FQR:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures

- Q: Where is the geotextile

- Essence is also the beauty of the latest brand of science and technology crystallization of the product

- Q: Characteristics of filament geotextile

- It can replace the traditional engineering materials and construction methods, construction safer, and contribute to environmental protection, can be more economical, effective and lasting solution to the basic problems in the construction. Filament geotextile has good mechanical function, good water permeability, and can be anti-corrosion, anti-aging, with isolation, filtration, drainage, protection, stability, reinforcement and other functions, to adapt to uneven grass-roots, Damage, creep small, long-term load can still maintain the original function. Filament geotextile characteristics: strength - the same weight under the specifications, the tensile strength are higher than other acupuncture non-woven fabrics; anti-ultraviolet light - with high UV resistance; high temperature resistance - resistance High temperature up to 230 ℃, high temperature remains structural integrity and the original physical properties; permeability and flat drainage - geotextile thick and is needle-shaped, with good surface drainage and vertical permeability, years later Can maintain this performance; creep resistance - geotextile creep resistance is better than other geotextiles, so long effect is good. It can resist the erosion of common chemical substances in soil and resistance to gasoline, diesel and other corrosion; ductility - geotextile under a certain stress has a good elongation, so that it can adapt to uneven irregular base; Cloth technical features: thick geotextile, geotextile can guarantee the three-dimensional porosity, is conducive to the realization of excellent hydraulic performance. Geotextile break strength has a great advantage, especially for retaining walls and embankment reinforcement. Geotextile indicators are more than the national standard, is an excellent geotextile reinforced materials.

- Q: How do geotextiles help in preventing the growth of weeds?

- Geotextiles help in preventing the growth of weeds by acting as a physical barrier between the soil and the environment. These permeable fabrics are designed to allow water and air to pass through but inhibit the growth of weeds by blocking sunlight, which is essential for weed germination and growth. Additionally, geotextiles can also prevent weed seeds from reaching the soil, thus minimizing the potential for weed growth.

- Q: Are geotextiles resistant to biological clogging?

- Yes, geotextiles are generally resistant to biological clogging. They are designed to have a high permeability and filtration properties, which help prevent the accumulation of organic matter and clogging by biological agents such as bacteria and algae.

- Q: What are the key factors to consider when selecting a geotextile?

- When selecting a geotextile, some key factors to consider are the specific application requirements, the type and strength of the geotextile, its permeability, durability, and compatibility with the surrounding soil or materials. Additionally, factors such as the installation method, environmental conditions, and budget should also be taken into account.

- Q: What glue can clay stickers glue?

- Geotextiles generally do not need to glue glue, because the geotextile is made of polyester staple fiber acupuncture, the product itself has a lot of small pores, the use of glue bonding not only a waste of glue, bonding effect is not good. Geotextile in the project is generally used in the hand-type sewing machine suture, suture geotextile not only glue glue than the geotextile solid and reliable, and the construction of geotextile suture is also much higher than the construction of glue with geotextile Speed, while the cost of sewing geotextile is also much lower than the cost of glue bonding geotextile. Generally in the project to play the effect of impervious geomembrane, composite geomembrane (also known as composite geotextile) can use glue bonding. Adhesive glue can be purchased in the geomembrane manufacturer, of course, you can also buy in the local building materials market, waterproof plastic or KS geomembrane special glue. These two glue can also be used to bond geotextiles.

- Q: Geotextile wholesale price of how much money, geotextile fabric manufacturers latest offer

- Geotextile wholesale, ranging from 5000-9000 yuan a ton. Geotextile manufacturers to answer your questions

- Q: What are the specifications for geotextiles and geogrids commonly used on expressways?

- You are the production, or sales, or procurement, the question asked, what model is the designer's decision

- Q: Do you have to have a mattress on the geotextile?

- 1, geotextile must be washed back to fill or sand protective layer and light compaction to prevent the subsequent construction of the destruction of geotextile, punctured and so on. But also a transition zone, to ease the upper load on the geotextile extrusion, tensile force and so on. 2, "Geotextile Construction Code QB / SNGSG-2004" and "Geosynthetics Application Technical Specifications GB / T-2017" backfill requirements: 1) timely backfill materials, backfill stone maximum drop of not more than 300mm, Heavy earth stones should not roll on the slope of the rolling; 2) fill the compaction should meet the design requirements, backfill 300mm loose layer, light compaction. 3, geotextile introduction: 1), geotextile by synthetic fiber through acupuncture or weaving made of permeable geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Advantages: geotextile with excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with a light weight, high tensile strength, good permeability, high temperature, resistance to Freezing, anti-aging, corrosion-resistant advantages. 2), Disadvantages: in the rigid base waterproof requirements are not applicable (tensile rate does not meet the requirements), easy to break, scratches and so on.

- Q: Can the geotextile of the filter layer be constructed?

- Light rain laying fast enough to be careful supervision Oh

Send your message to us

Geotextile Paper Fiberglass Geogrid for Roadbed Reinforcement in Highway, Railway, and Municipal Road

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords